Vous êtes à la recherche de la meilleure profileuse pour quilles en acier léger ? Vous êtes au bon endroit ! Dans cet article, nous allons examiner quelques-unes des meilleures profileuses pour quilles en acier léger disponibles sur le marché. Après avoir lu cet article, vous serez en mesure de prendre une décision éclairée quant à la machine la mieux adaptée à vos besoins.

Introduction

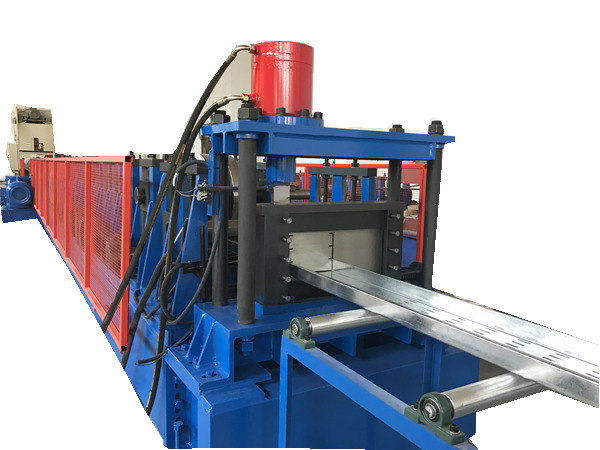

La profileuse pour quilles en acier léger est un type de laminoir destiné à la production de barres d'acier léger. Il a été développé ces dernières années comme un nouveau type de laminoir pour la production de feuilles et de plaques d'acier léger. Les principaux avantages de cette machine sont sa grande capacité de production, ses faibles coûts d'exploitation et la bonne qualité du produit.

Cette machine est dotée d'un système de laminage à ondes continues et peut produire des barres d'un diamètre de 0,1 à 2 mètres et d'une longueur maximale de 3,2 mètres. Elle peut laminer des tôles d'acier léger à raison de 600 à 800 mètres par heure et produire des barres rondes d'un diamètre interne moyen de 0,8 à 1,2 mètre.

Qu'est-ce qu'une profileuse pour quilles en acier léger ?

Une profileuse pour quilles en acier léger est une machine utilisée pour former des quilles en acier léger. Ces machines sont généralement utilisées dans l'industrie de la construction navale, car elles permettent de créer des quilles beaucoup plus légères que les quilles en acier traditionnelles. Elles sont également beaucoup plus faciles à souder, ce qui en fait une option plus rentable que les techniques traditionnelles de formage de quilles.

Pourquoi avez-vous besoin d'une profileuse pour quilles en acier léger ?

Il existe de nombreuses raisons pour lesquelles vous pourriez avoir besoin d'une quille en acier léger forme rouleau machine. Peut-être cherchez-vous à créer un nouveau modèle de bateau qui nécessite une coque plus légère, ou souhaitez-vous réduire le poids d'un bateau existant. Quelle que soit votre raison, une profileuse pour quilles en acier léger peut vous aider à réaliser le travail rapidement et facilement.

Une quille en acier léger est l'une des parties les plus importantes d'un bateau. Elle assure la stabilité du bateau et l'empêche de chavirer. Pour créer une quille en acier léger, il faut commencer par une base solide. C'est là qu'une profileuse pour quilles en acier léger peut s'avérer utile.

En utilisant cet outil, vous pouvez rapidement et facilement créer une base légère mais solide pour votre quille. Vous n'avez pas à vous soucier des erreurs : la machine guide automatiquement le métal dans des formes précises. Et comme la pression exercée est minime, il n'y a pratiquement aucun risque de dommage ou de déformation.

-

Machine de formage de rouleaux à deux étages

Machine de formage de rouleaux à deux étages -

Machine de formage de rouleaux d'acier de couleur

Machine de formage de rouleaux d'acier de couleur -

Machine de formage de panneaux muraux

Machine de formage de panneaux muraux -

Machine de formage de rouleaux IBR

Machine de formage de rouleaux IBR -

Machine de formage de rouleaux de carreaux émaillés demi-ronds

Machine de formage de rouleaux de carreaux émaillés demi-ronds -

Machine de formage de rouleaux de panneaux R

Machine de formage de rouleaux de panneaux R -

Cintreuse de toit automatique

Cintreuse de toit automatique -

Snap clip lock panneau de toit en métal formant la machine

Snap clip lock panneau de toit en métal formant la machine -

panneau de panneau de conteneur d'expédition formant la machine

panneau de panneau de conteneur d'expédition formant la machine

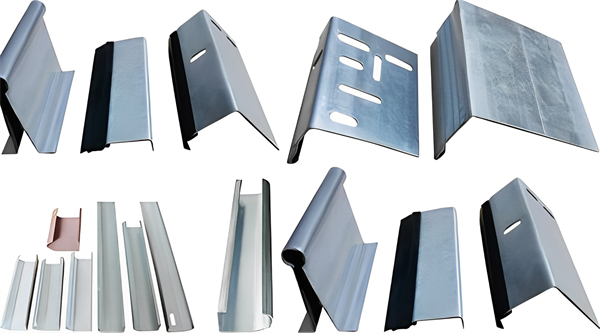

Types de profileuses pour quilles en acier léger

Il existe trois types de profileuses pour quilles en acier léger : hydraulique, pneumatique et électrique. Chacune a ses propres avantages et inconvénients.

Les profileuses hydrauliques utilisent la pression hydraulique pour forcer le métal autour d'une matrice cylindrique. Il s'agit du type de profileuse de quille le plus courant et le moins coûteux à l'achat et à l'utilisation.

Les profileuses pneumatiques utilisent de l'air comprimé pour former l'acier autour d'une matrice cylindrique. Elles sont plus chères à l'achat que les machines hydrauliques, mais elles sont plus rapides et plus faciles à utiliser.

Les profileuses électriques utilisent un moteur électrique pour former l'acier autour d'une matrice cylindrique. Elles sont plus chères que les machines pneumatiques ou hydrauliques, mais elles sont plus rapides et comportent moins de pièces mobiles.

Quels sont les avantages de posséder une profileuse pour quilles ?

Posséder une profileuse pour quilles en acier léger présente de nombreux avantages. La machine est très fiable et facile à utiliser, ce qui en fait un choix idéal pour les petites entreprises ou les entrepreneurs. Voici cinq des principaux avantages :

- Fiabilité - La profileuse pour quilles en acier léger est très fiable et facile à utiliser, ce qui en fait un choix idéal pour les petites entreprises ou les entrepreneurs.

- Vitesse - La machine est très rapide, ce qui la rend idéale pour la production de produits en acier de haute qualité.

- Coût - L'acquisition d'une profileuse pour quilles en acier léger est relativement abordable, ce qui en fait une bonne option pour les acheteurs soucieux de leur budget.

- Durabilité - La machine est conçue pour durer, ce qui signifie qu'elle durera longtemps et qu'elle vous offrira des années d'utilisation sans problème.

- Efficacité - La profileuse pour quilles en acier léger est très efficace, ce qui signifie que vous obtiendrez des produits de haute qualité à faible coût.

Quels sont les inconvénients d'une profileuse pour quilles ?

L'utilisation d'une profileuse pour quilles en acier léger présente des inconvénients. Tout d'abord, l'acier n'est pas aussi résistant que les aciers plus lourds. Cela peut entraîner des ruptures lors de l'utilisation de la machine. Ensuite, il est difficile de produire de grandes formes avec ce type de machine. Enfin, le processus est lent et difficile, ce qui peut entraîner des retards de production.

Conclusion

Merci de lire notre article sur la meilleure profileuse pour quilles en acier léger. Dans cet article, nous avons partagé nos meilleurs choix pour les meilleures profileuses pour quilles en acier léger sur le marché aujourd'hui. Nous espérons que ces informations vous ont été utiles et qu'elles vous aideront à prendre une décision plus éclairée lors de la sélection de la profileuse idéale pour vos besoins. N'hésitez pas à nous contacter si vous avez besoin d'aide pour trouver la bonne machine pour votre entreprise ou votre projet !