If you are in the construction or roofing business, you might have heard of the gutter roll forming machine. A gutter roll forming machine is a specialized piece of equipment used to fabricate gutters for residential and commercial buildings. It is an essential tool that helps contractors produce high-quality and custom-made gutters to meet their clients’ unique needs.

In this article, we will provide a comprehensive guide on the gutter roll forming machine. We will discuss what it is, how it works, the types of gutter roll forming machines available in the market, and their applications. We will also touch on the benefits of using a gutter roll forming machine, its maintenance, and safety measures to consider when using the machine.

1 परिचय

Gutters are an essential component of any building, as they help protect the roof, walls, and foundation from water damage. Gutter installation requires accuracy and precision, which is why the use of a gutter roll forming machine is crucial. A gutter roll forming machine is a specialized equipment that produces custom-made gutters with minimal waste and high efficiency.

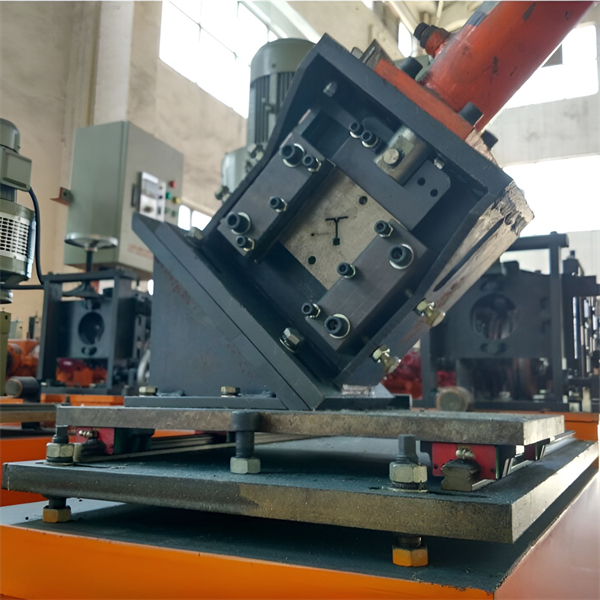

A gutter roll forming machine is a specialized piece of equipment used in the construction and roofing industry to fabricate gutters for residential and commercial buildings. The machine operates by passing a continuous strip of metal through a series of rollers, which bend and shape the metal into a gutter profile. The gutter profile can be customized according to the client’s specifications, such as the size, shape, and color. Gutter roll forming machines are essential tools that help contractors produce high-quality and custom-made gutters to meet their clients’ unique needs.

2. How Does a Gutter Roll Forming Machine Work?

The operation of a gutter roll forming machine is relatively simple. The machine consists of a series of rollers arranged in a particular sequence, which bend and shape the metal into a specific gutter profile. The rollers are usually adjustable to allow for the production of different gutter sizes and shapes.

The process begins with the insertion of a continuous strip of metal into the machine. The metal strip passes through a series of rollers that gradually bend and shape it into the desired profile. The finished product is then cut to the desired length and shape.

3. Types of Gutter Roll Forming Machines

There are several types of gutter roll forming machines available in the market, each with unique features and capabilities. The most common types of gutter roll forming machines are:1. Single Profile Machines

Single profile machines are the simplest type of gutter roll forming machines. They are designed to produce a single gutter profile at a time. These machines are ideal for small to medium-sized businesses that require a limited number of gutter profiles.

2. Dual Profile Machines

Dual profile machines can produce two different gutter profiles at the same time. They are ideal for businesses that require more than one type of gutter profile.

3. Multiple Profile Machines

Multiple profile machines can produce multiple gutter profiles simultaneously. They are ideal for large businesses that require a wide range of gutter profiles.

4. Applications of Gutter Roll Forming Machines

Gutter roll forming machines have a wide range of applications in the construction and roofing industry. Some of the common applications of gutter roll forming machines include:

1. Residential and Commercial Gutter Installation

Gutter roll forming machines are commonly used in the installation of gutters in residential and commercial buildings. The machines produce custom-made gutters that fit perfectly and efficiently.

2. Industrial Applications

Gutter roll forming machines are also used in various industrial applications, such as the production of ducts, pipes, and other metal products.

5. Benefits of Using a Gutter Roll Forming Machine

There are several benefits to using a gutter roll forming machine, including:

1. Customization

Gutter roll forming machines allow for the production of custom-made gutters to meet the unique needs of the client.

2. Speed and Efficiency

Gutter roll forming machines are capable of producing gutters quickly and efficiently, which helps to save time and money.

3. Cost-Effective

Gutter roll forming machines are cost-effective in the long run, as they reduce material waste and improve efficiency.

4. Consistency and Accuracy

Gutter roll forming machines produce gutters with consistent quality and accuracy, which helps to ensure customer satisfaction.

6. Maintenance of Gutter Roll Forming Machines

To ensure the longevity and efficiency of the gutter roll forming machine, regular maintenance is crucial. Some of the maintenance practices to consider include:

1. Regular Cleaning

The machine should be regularly cleaned to prevent the accumulation of debris and dirt.

2. Lubrication

The machine should be well lubricated to ensure smooth operation and prevent wear and tear.

3. Inspection and Repairs

Regular inspection and repairs are necessary to identify and fix any mechanical issues before they escalate.

7. Safety Measures to Consider When Using Gutter Roll Forming Machines

When using a gutter roll forming machine, it is essential to consider the following safety measures:

- Always wear protective gear, such as gloves, eye protection, and ear protection.

- Avoid loose clothing and tie back long hair to prevent entanglement in the machine.

- Always operate the machine according to the manufacturer’s instructions.

- Keep the work area clean and free of clutter.

- Never place hands or fingers near the rollers while the machine is in operation.

8. Conclusion

Gutter roll forming machines are an essential tool in the construction and roofing industry. They produce high-quality, custom-made gutters quickly and efficiently, reducing material waste and improving efficiency. Proper maintenance and safety measures are crucial to ensure the longevity and safety of the machine.

9. FAQs

- What types of materials can be used with a gutter roll forming machine?

- Gutter roll forming machines can be used with a wide range of materials, including aluminum, steel, and copper.

- How long does it take to produce gutters with a gutter roll forming machine?

- The production time depends on the size and complexity of the gutter profile. However, gutter roll forming machines are generally fast and efficient, producing gutters within minutes.

- Can gutter roll forming machines produce gutters of different shapes and sizes?

- Yes, gutter roll forming machines are highly customizable and can produce gutters of different shapes, sizes, and colors.

- Is it safe to operate a gutter roll forming machine?

- Yes, it is safe to operate a gutter roll forming machine if proper safety measures are followed.

- How often should a gutter roll forming machine be inspected?

- A gutter roll forming machine should be inspected regularly, at least once a month, to identify and fix any mechanical issues before they escalate.