Choosing the right roofing sheet roll forming machine for your needs can be a tricky task. You need to know what you are looking for and become familiar with the various types of machines on the market. This article will give you an overview of the different types of machines available, as well as some helpful tips on making your decision.

Benefits of a Roofing sheets Roll Forming Machine

A roofing sheets roll forming machine can offer a number of benefits for your business. Perhaps the most significant benefit is the speed at which these machines can produce roof panels. A good quality machine can produce up to 30 feet of roof panel per minute, which is a huge time-saver compared to traditional methods of manufacturing roof panels.

Another big benefit is the consistency that a roll forming machine can provide. When you’re manually fabricating roof panels, it’s very easy to end up with inconsistencies in the finished product. But when you use a roll forming machine, the panels will all be exactly the same size and shape, every single time. This leads to a much higher quality final product that your customers will be happier with.

Finally, using a roll forming machine can help to reduce your material costs. Because the panels are produced so quickly and accurately, there is very little waste material left over at the end of the process. This means that you can save money on your raw materials, and ultimately pass those savings on to your customers.

The Right Type of Roofing sheets Roll Forming Machine for You

There are a few factors you should consider when choosing a roofing sheets roll forming machine. The first is the type of roofing material you’ll be using. If you’re using a standard asphalt shingle, you’ll need a different machine than if you’re using a metal roofing panel. The second factor is the width of your roof. A wider roof will require a different machine than a narrower one. Finally, consider the speed at which you want your machine to operate. A faster machine will be more expensive, but it will also get the job done quicker.

Once you’ve considered all of these factors, you can start looking at specific models of machines. There are a few reputable brands that make roofing roll forming machines, so do some research to see which one is right for you. Once you’ve found the perfect machine, be sure to read the instructions carefully before operating it. With proper care and maintenance, your new roofing sheets roll forming machine will provide years of service.

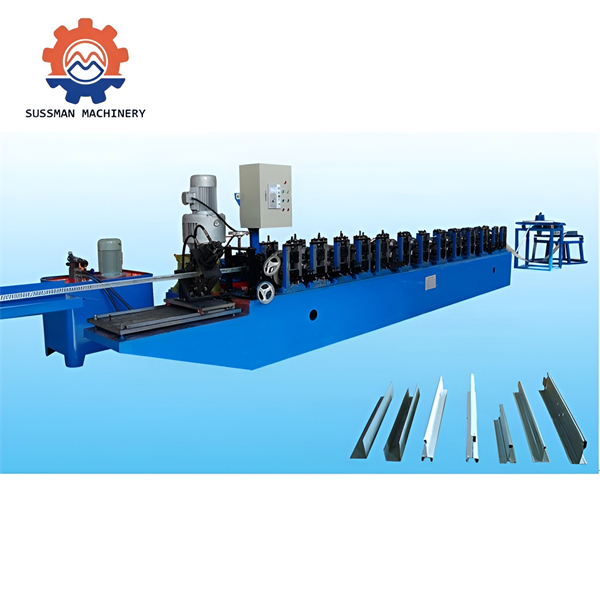

Different Types of Roofing sheets Roll Forming Machines

There are many different types of roofing sheets roll forming machines on the market today. Each type of machine has its own strengths and weaknesses, so it’s important to choose the right machine for your particular application. Here are some of the most common types of roofing roll forming machines:

- Single-pass Roofing Roll Forming Machine: This type of machine is ideal for small jobs or production runs. It can produce a variety of shapes and sizes, and it’s relatively easy to operate. However, it can be slower than other types of machines, and it may not be able to produce as large or complex shapes.

- Multi-pass Roofing Roll Forming Machine: This type of machine is designed for larger jobs or production runs. It can produce a variety of shapes and sizes, and it can be faster than a single-pass machine. However, it may be more difficult to operate, and it may not be able to produce as large or complex shapes.

- Continuous Roofing Roll Forming Machine: This type of machine is designed for large jobs or continuous production runs. It can produce a variety of shapes and sizes, and it can be very fast. However, it may be more difficult to operate, and it may not be able to produce as large or complex shapes.

-

Double deck roll forming machine

Double deck roll forming machine -

Color steel roll forming machine

Color steel roll forming machine -

Wall panel roll forming machine

Wall panel roll forming machine -

IBR roll forming machine

IBR roll forming machine -

Half round glazed tile roll forming machine

Half round glazed tile roll forming machine -

R panel roll forming machine

R panel roll forming machine -

Automatic roof curving machine

Automatic roof curving machine -

snap clip lock metal roof panel roll forming machine

snap clip lock metal roof panel roll forming machine -

shipping container board panel Roll Forming Machine

shipping container board panel Roll Forming Machine

Comparisons Between Brands

When it comes to choosing a roofing sheets roll forming machine, there are a few key things to keep in mind. First, you need to decide what type of metal roofing you want to use. There are machines that can handle both aluminum and steel, but if you have a preference, it’s important to choose a machine that can accommodate your preferred material.

Once you’ve decided on the type of metal roofing you want to use, you need to compare different brands of machines. There are a few key factors to consider when making your decision:

- The price of the machine: Be sure to get quotes from multiple manufacturers before making your final decision.

- The quality of the machine: It’s important to choose a well-made machine that will last for years. Ask around for recommendations or read online reviews before making your purchase.

- The warranty: Make sure the manufacturer offers a good warranty in case anything goes wrong with the machine.

By keeping these factors in mind, you’ll be able to find the best roofing sheets roll forming machine for your needs.

Conclusion

When it comes to choosing the right roofing sheets roll forming machine, it is important to consider your specific needs and requirements. There are many different types and models of machines on the market, so it is important to do your research in order to find the one that best suits your needs. With a little bit of time and effort, you can find the perfect machine for your business, ensuring that your roofing projects are completed efficiently and effectively.

FAQ

What is roll forming machine?

A roll forming machine (or metal forming machine) fabricates specific configurations out of long strips of metal, most commonly coiled steel. In most applications, the required cross-section profile of the piece is specifically designed for the machine to bend the metal as necessary.