Looking for the right roof panel roll forming machine can be a daunting task. There are many nuances to take into consideration when you’re deciding which one will be best for your needs. But don’t worry! We have all the information you need to make an informed decision about what kind of roof panel roll forming machine is best for you.

What is a roof panel roll forming machine?

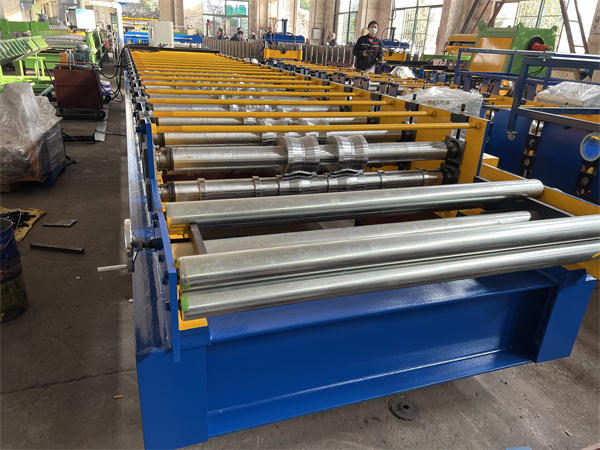

A roof panel roll forming machine is a piece of equipment that is used to create long, continuous sheets of metal roofing. These machines typically have a series of rollers that progressively shape the metal as it passes through them. In order to produce high-quality panels, it is important to select a machine with well-designed rollers and sturdy construction.

When shopping for a roof panel roll forming machine, there are several factors to keep in mind. First, consider the size and weight capacity of the machine. It should be large enough to accommodate the panels you plan to produce, but not so large that it is difficult to move or set up. Second, look at the quality of the rollers. They should be made from durable materials and designed to minimize wear and tear. Finally, make sure the machine is backed by a good warranty in case any parts break or malfunction.

What are the different types of roof panel roll forming machines?

When it comes to choosing a roof panel roll forming machine, there are a few different factors that you’ll need to consider. Here are the different types of machines that you’ll need to choose from:

- Single-Pass Roof Panel Roll Forming Machine: This type of machine is best suited for projects that require a high degree of accuracy and consistency. With this machine, the metal sheets are fed into the machine in a single pass, which helps to ensure that each sheet is formed correctly.

- Multi-Pass Roof Panel Roll Forming Machine: This type of machine is best suited for projects that require a higher degree of flexibility. With this machine, the metal sheets are fed into the machine in multiple passes, which allows for more customization and flexibility when it comes to the final product.

- Continuous Roof Panel Roll Forming Machine: This type of machine is best suited for projects that require a high volume of production. With this machine, the metal sheets are fed into the machine continuously, which helps to increase productivity and efficiency.

-

Double deck roll forming machine

Double deck roll forming machine -

Color steel roll forming machine

Color steel roll forming machine -

Wall panel roll forming machine

Wall panel roll forming machine -

IBR roll forming machine

IBR roll forming machine -

Half round glazed tile roll forming machine

Half round glazed tile roll forming machine -

R panel roll forming machine

R panel roll forming machine -

Automatic roof curving machine

Automatic roof curving machine -

snap clip lock metal roof panel roll forming machine

snap clip lock metal roof panel roll forming machine -

shipping container board panel Roll Forming Machine

shipping container board panel Roll Forming Machine

How much do roof panel roll forming machines cost?

The cost of roof panel roll forming machines can vary depending on the manufacturer and the specific features and capabilities that you need. However, you can typically expect to pay between $25,000 and $75,000 for a quality machine. When choosing a machine, it’s important to consider the initial investment as well as the long-term costs of ownership and operation.

How to pick the right roof panel roll forming machine for your needs?

When it comes to choosing the right roof panel roll forming machine, there are a few things you need to take into account. In this article, we will guide you through everything you need to know in order to make the best decision for your business.

The first thing you need to consider is the type of roof panels you will be manufacturing. There are many different types of roof panels on the market, and each one has its own specific set of requirements. Once you know the type of roof panel you need to produce, you can narrow down your choices of machines.

Another important factor to consider is the speed at which you need the machine to operate. Some machines are designed for high-speed production, while others are better suited for lower speeds. You should also consider the amount of space you have available for the machine. If you have a limited amount of space, then a compact machine may be your best option.

Finally, you need to think about the budget you have available for the machine. There are many different models on the market, and they all come with different price tags. It is important to find a machine that fits within your budget so that you don’t overspend on something that isn’t necessary.

By following these simple tips, you should be able to find the perfect roof panel roll forming machine for your business.

Conclusion

Picking the right roof panel roll forming machine is essential to ensuring that your business runs smoothly. With so many options on the market, it can be difficult to know which one is right for you. However, by taking into account your specific needs and budget, you can narrow down your options and find the perfect machine for your business. We hope that our tips have helped you pick the right roof panel roll forming machine for your needs.

FAQ

What industries use roll forming?

Many industries use roll formed parts such as the automobile industry, tools, and dyes industry, metal furniture industry, construction, railways and others. There are also several types of roll forming processes such as roll bending, flat rolling, foil rolling, ring rolling and controlled rolling.