High speed Guard Railway Crash barrier roll forming machine is to produce galvanized container body sheet, this line is composed by uncolier with coil car, guiding & feeding device, roll forming machine, welding device, hydraulic cutter, receiving table, hydraulic system, electric control system, this machine is to make material thickness 2.0-2.5mm.

Profile is according to the customer’s requirement.

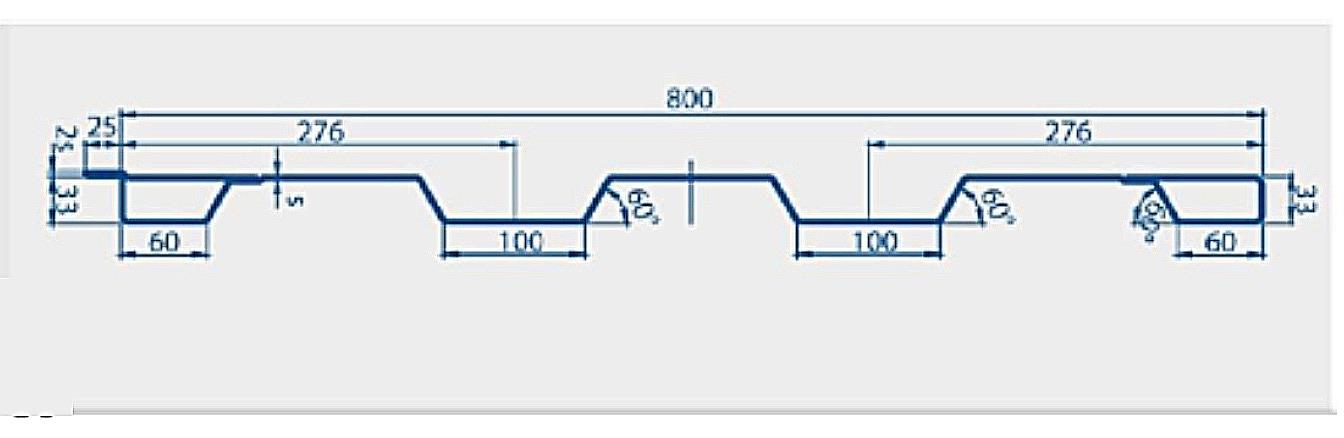

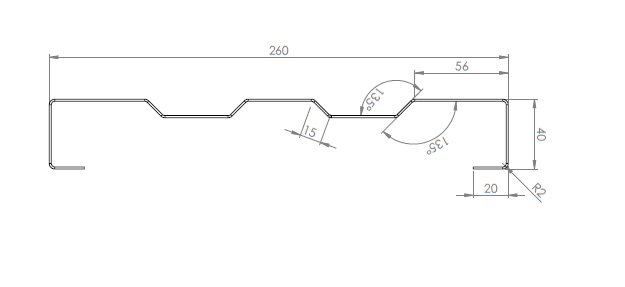

Profile Drawing of High speed Guard Railway Crash barrier roll forming machine

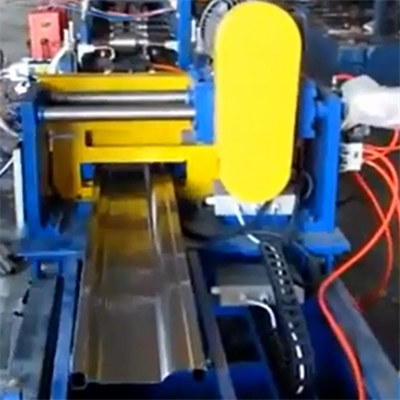

Sample made before

Working flow of High speed Guard Railway Crash barrier roll forming machine

Uncoiling—feeding& leveling—Roll forming—welding—-Saw cutting—Products collecting

| S.N | Equipment name | Quantity |

| 1 | 5T hydraulic un-coiler | 1 set |

| 2 | Feeding&leveling | 1 set |

| 3 | Main roll forming machine | 1 set |

| 4 | Laser welding device | 1 set |

| 5 | Stop saw cutting | 1 set |

| 6 | Control box system | 1 set |

| 7 | Out table | 1 unit |

| 8 | Spare parts | 1 package |

| 9 | Safety cover | 1 set |

Details of each composition

1. 5 tons hydraulic decoiler

- Coil inner Diameter: ¢460-520mm

- Max out diameter of the coil: ¢1500mm

- Max Coil Width: 1250mm

2. Leveling and feeding

- 7 rolls leveling, 3 rolls up and 4 rolls down, roller leveler rolls are smaller, get flatting better

- Diameter is Ø 70mm, chrome and HRC60 heat treatment to secure the smooth surface

3. Main Roll forming machine technique data

- Suitable Plate Material: thickness: 2.0-2.5mm, Galvanized steel or blank steel 250mpa-550mpa

- Working Speed: About 3-5 meters / min

- Forming machine: about 35 stations

- Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

- Material of Shaft: 45# Advanced Steel (Diameter: 75mm), thermal refining

- Driven system: Gearbox

- Main Power with reducer: 2*11KW Chinese Famous

- Cutting method: Stop saw cutting

- The whole machine is controlled by PLC.

- PLC–Delta, English and Chinese Language

- Encoder–Omron, Japan

- Electric parts–Schneider

4. Laser welding

5. Saw Cutting

- Blade number: 1 set

- Cutting after forming: Cut the sheet after roll forming to required length

- Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

- Length measuring: Automatic length measuring

- Tolerance of length: 6m±1.0mm

6. Out tables

- Length: 4 meters

- Number: 1 unit

What is crash barrier roll forming machine?

A crash barrier roll forming machine is a specialized industrial machine used to manufacture crash barriers, also known as guardrails or safety barriers. Crash barriers are protective barriers typically installed on roads, highways, bridges, and other transportation infrastructure to prevent vehicles from veering off the road, colliding with obstacles, or crossing into opposing traffic lanes.

The roll forming machine is designed to efficiently produce crash barriers by continuously shaping and forming metal sheets into the desired profile. The machine operates by feeding a coil of metal, usually steel, into the system. The metal sheet passes through a series of rollers and dies that gradually shape it into the specific cross-sectional profile of the crash barrier.

The roll forming process allows for precise and consistent production of crash barriers with uniform dimensions and structural integrity. The machine can also incorporate various features, such as corrugations or perforations, for improved strength and performance. Additionally, the machine may have provisions for cutting the formed barrier into the required lengths.

Crash barrier roll forming machines are often used in the manufacturing industry and are capable of producing high volumes of crash barriers efficiently. The resulting crash barriers are durable, impact-resistant, and designed to enhance road safety by redirecting or absorbing the energy of a vehicle during a collision.

What is the purpose of a guard rail roll forming machine?

A guardrail roll forming machine serves the purpose of manufacturing guardrails, also known as guard rails or safety barriers. Guardrails are protective barriers typically installed along roads, highways, bridges, and other transportation infrastructure to enhance safety and prevent vehicles from leaving the roadway or colliding with obstacles.

The roll forming machine specifically designed for guardrails allows for efficient and continuous production of these safety barriers. The machine takes in a coil of metal, often steel, and processes it through a series of rollers and dies. These components shape the metal into the desired cross-sectional profile of the guardrail.

The primary purpose of a guardrail roll forming machine is to produce guardrails with consistent dimensions, structural integrity, and high manufacturing precision. The roll forming process ensures that the guardrails have uniform shapes, sizes, and strength throughout their length. This uniformity is crucial for the proper installation and performance of the guardrails.

Guardrail roll forming machines can produce various types of guardrail profiles depending on the specific requirements of the road or highway project. The profiles may include W-beam guardrails, thrie-beam guardrails, or other custom profiles. These profiles are designed to effectively redirect or absorb the impact energy of a vehicle during a collision, minimizing the risk of severe accidents or vehicle rollovers.

By utilizing a guardrail roll forming machine, manufacturers can streamline the production process, increase efficiency, and ensure the availability of high-quality guardrails for road safety installations.

top 5 highway guardrail roll forming machine manufacturers in China

- Sussman Machinery(Wuxi)Co., Ltd. is specialized in manufacturing shape steel cold roll forming machines about 20 years, exporting slitting line and whole group international trade business.We export to more than 100 countries, and our customers are around the world, especially Australia, South America, Europe, India, Middle East, Northern Europe and North Africa. Furthermore, we wish to build the best machine for customers, our core values are “Quality, Efficiency, Credibility & Integrity”, which can firmly and solidly support us to go far.

- Tianjin Haixing Imp & Exp Co., Ltd: Tianjin Haixing is a well-known manufacturer and exporter of roll forming machines, including highway guardrail roll forming machines. They offer a range of equipment with advanced technology and reliable performance.

- Jiangsu Huazhong Roll Forming Machine Co., Ltd: Jiangsu Huazhong specializes in the production of roll forming machines for various applications, including highway guardrails. They have a strong focus on quality control and have gained a good reputation in the industry.

- Wuxi Suhang Machinery Manufacturing Co., Ltd: Wuxi Suhang is a leading manufacturer of roll forming machines, offering a comprehensive range of equipment, including highway guardrail roll forming machines. They are known for their innovative designs and high-quality manufacturing.

- Hangzhou Roll Forming Machinery Co., Ltd: Hangzhou Roll Forming Machinery is a well-established manufacturer of roll forming equipment, including highway guardrail roll forming machines. They have extensive experience in the industry and provide reliable and efficient machines.

Reviews

There are no reviews yet.