China has been renowned for their manufacturing skills and quality products. China rolls, which are thin sheets of metal that are bent into a circular shape in the middle and rolled outward to form a tube, are one such example. This new metal roof roll forming machine is a tool that makes bending these thin sheets of metal easy. The machine does not require hand-operated tools or other machines, just one operator. In addition, the machine can be run unattended.

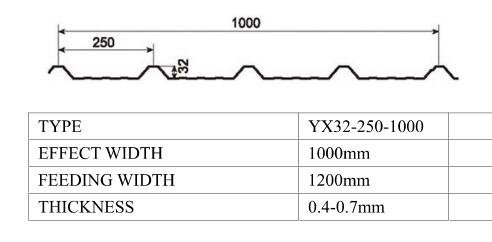

Profile Drawing of roof panel China roll forming machine

Technical process of roof panel China roll forming machine

Decoiler→ feeding with guide→roll forming→servo following cutting→conveyor belt→Stackers

Technical parameter of roof panel China roll forming machine

- Rolling Speed: about 30-40m/min

- Materials to be processed: Galvanized steel, Aluzinc, PPGI from 0.3 mm to 0.8 mm

- Maximum length of the sheet to be unloaded: 6 m

- Control System: PLC with touch screen

- Roller Stations: about 20 stations

- Roller Material : 45# forge steel, coated with chrome

- Shaft Material and DIA: ¢76mm,material is 45# forge steel, Chrome with quenching

- Motor Power: 22kw main motor

- Hydraulic power:7.5kw

- Power supplier:380V, 50HZ,3 phase

- Way Of Drive:Gearbox

- The size of the forming machine: About 11,500*1700*1200mm

- Machine weight: about 10 tons

Machine List of roof panel roll forming machine

|

Machine list

|

10 tons de-coiler with arm device | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| Servo following cutting | 1 set | |

| Control box | 1 unit | |

| Hydraulic station | 1 unit | |

| 3 meters conveyor belt | 1 set | |

| 6m auto stacker | 1 set | |

| Safety cover | 1 set | |

| Spare parts | 1 package |

Technical Data of roof panel roll forming machine:

10 tons hydraulic de-coiler with coil car

- Coil inner Diameter: ¢508-610mm

- Max out diameter of the coil: ¢1250mm

- Max Coil Width: 1250mm

Main roll forming machine

Servo following Cutting device

- Cutting motion: Servo following cutting

- Material of blade: CR12mov with heat treatment

- Length & quantity measurement automatically;

- The cutting thickness: 0.2- 0.6mm

- Hydraulic Station Power: .5 KW

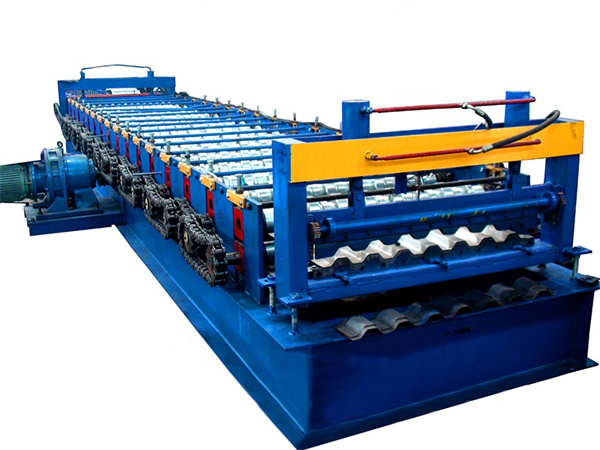

what is metal roof roll forming machine?

A metal roof roll forming machine is a specialized piece of equipment used in the manufacturing process of metal roofs. It is designed to efficiently and accurately shape flat metal sheets into specific roof profiles through a continuous roll forming process.

The machine typically consists of a series of rollers and tooling sets that gradually bend and shape the metal sheet to the desired profile. The metal sheet is fed into the machine, and as it passes through the rollers, it undergoes a series of forming operations, including bending, folding, and cutting. The rollers and tooling sets are carefully designed to achieve precise dimensions and shapes for the final metal roof panels.

Metal roof roll forming machines are available in various configurations to accommodate different roof profiles, materials, and production capacities. They can handle different types of metal sheets, such as steel, aluminum, or copper, with varying thicknesses. The machines may also include additional features such as automatic feeding systems, cutting mechanisms, and control systems for efficient and automated production.

The use of a metal roof roll forming machine offers several advantages, including high production speed, consistent quality, precise dimensions, and reduced labor costs. It allows for the mass production of metal roof panels with uniform profiles and ensures faster installation on construction sites. These machines are widely used in the roofing industry for residential, commercial, and industrial applications.

Benefits of China roof roll forming machine

- Cost-effectiveness: China is known for its competitive pricing in manufacturing. Chinese roof roll forming machines are often more affordable compared to machines from other countries. This cost advantage allows businesses to invest in high-quality equipment while minimizing their expenses.

- Wide range of options: China has a vast and diverse manufacturing industry, offering a wide range of roof roll forming machines. You can find machines with different specifications, capacities, and features to suit your specific needs. Whether you require machines for small-scale operations or large-scale industrial production, China can provide suitable options.

- Advanced technology: China has made significant strides in adopting and innovating manufacturing technologies. Chinese roof roll forming machines often incorporate advanced automation, precision engineering, and efficient control systems. These technological advancements enhance productivity, accuracy, and overall performance, leading to higher efficiency and better product quality.

- Customization capabilities: Chinese manufacturers understand the importance of meeting specific customer requirements. They offer customization options for roof roll forming machines, allowing you to tailor the machine according to your unique needs. Whether it’s adjusting the dimensions, profiles, or materials, Chinese manufacturers can often accommodate customization requests.

- Quality construction: Chinese manufacturers prioritize the quality and durability of their products. They utilize high-quality materials, employ skilled technicians, and adhere to strict quality control measures during the manufacturing process. As a result, China roof roll forming machines are built to withstand heavy use, provide consistent performance, and have a longer lifespan.

- After-sales support: Many Chinese manufacturers provide comprehensive after-sales support, including technical assistance, training, and spare parts availability. This ensures that customers can receive timely support and maintenance services when needed, minimizing downtime and maximizing the efficiency of the machines.

- Global presence and reputation: Chinese manufacturers have established a strong presence in the global market for roof roll forming machines. They have gained a reputation for producing reliable equipment and delivering quality service. Their extensive distribution networks and global partnerships make it easier to access their products and services worldwide.

Where can I buy a china r panel roll forming machine?

If you’re looking for a China r panel roll forming machine, your best bet is to check out online retailers or physical stores that sell machine tools, such as Sussman roll forming machine. Additionally, many industrial supply stores have machines on display that they may be able to rent or sell.

Keep in mind that the price of a China r panel roll forming machine can vary significantly depending on the model and brand. Some models are cheaper than others, but all of them offer high quality Results. The best way to determine if a China r panel roll forming machine is right for you is to try it out in person.

top 5 China metal roof roll forming machine supplier

- Sussman Machinery(Wuxi)Co., Ltd. is specialized in manufacturing shape steel cold roll forming machines about 20 years, exporting slitting line and whole group international trade business. We have high technological background, advanced production equipment, strict inspection, matured after-sales work and thoughtful service.

- Liming Stamping Forming Machine Manufacture Co., Ltd.: Liming Stamping is another reputable manufacturer specializing in the production of roll forming machines. They offer various models suitable for car panel production and have been supplying their machines to both domestic and international markets.

- Haixing Industrial Group Co., Ltd.: Haixing Industrial Group is a well-established manufacturer of roll forming machines and has experience in producing car panel roll forming machines. They have a wide range of products and are known for their technical expertise and customer support.

- Botou Golden Integrity Roll Forming Machine Co., Ltd.: Golden Integrity is a reliable manufacturer of roll forming machines, including car panel roll forming machines. They have a strong presence in the Chinese market and have been exporting their machines to different countries.

- Xiamen Bogong Machinery Manufacturing Co., Ltd.: Bogong Machinery is a professional manufacturer of roll forming machines, and they offer a range of options for car panel production. They have gained a good reputation for their quality products and efficient customer service.

Reviews

There are no reviews yet.