Main specifications

| Items | Specifications |

| Material Thickness |

0.4-0.8 mm galvanized sheet G550

|

| Rolling Speed |

About 20 m/min line speed

|

| Roller Stations |

About 9 stations

|

| Roller Material |

45# Steel with quenching 60mm shaft

|

| Maim Motor Power | 5.5 kw |

| hydraulic station Power | 4 kw |

| Material Of Cutting |

CR12 with quench treatment

|

| Hardness | HRC58-62 |

| Tolerance | ±1.5mm |

| Electric Source |

380V, 50HZ,3 phase

Also can satisfy Customer’s require |

| Control System |

PLC control system

|

| Weight | About 2.5 tons |

| Way Of Drive |

1 inch single chain

|

| Size of machine |

Length 4500mm* Width 500mm* Height 800m

|

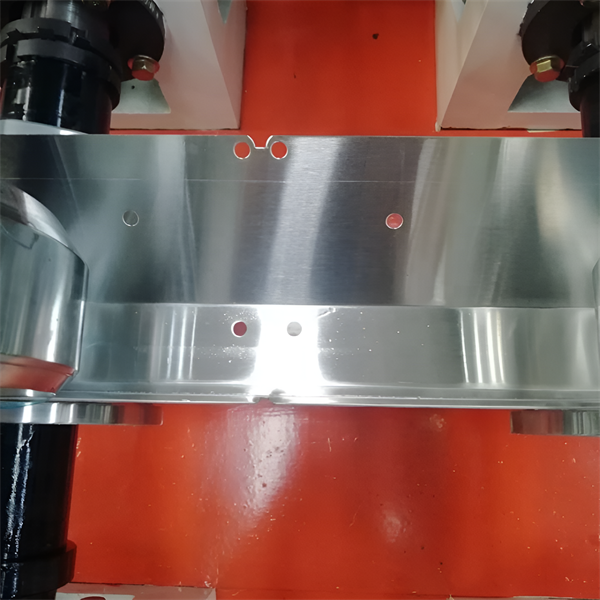

Profile Drawing

Machine List

| 3 ton passive de-coiler | 1 set |

| Main roll forming machine | 1 set |

| Cutting device | 1 set |

| PLC Control box | 1 unit |

| Hydraulic station | 1 unit |

| Out table | 1 unit |

| Safety cover | 1 Set |

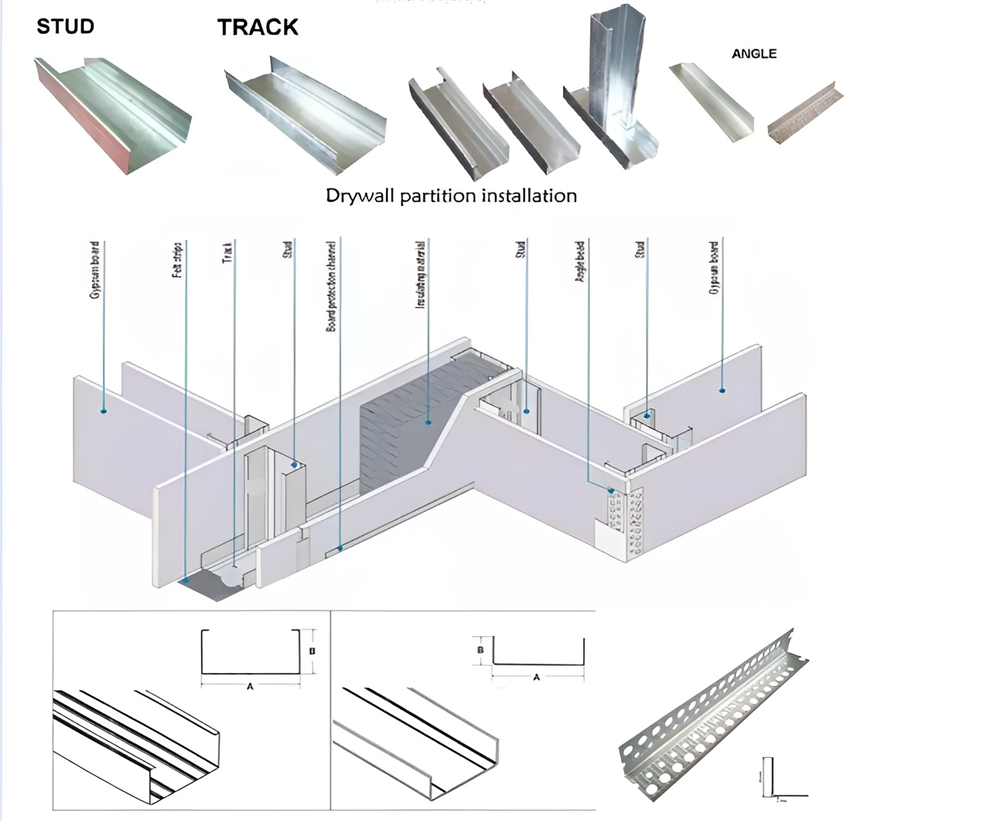

Application

Pratical Application

Steel building is a metal structure fabricated with steel for the internal support and for exterior cladding, as opposed tosteel framed buildings which generally use other materials for floors, walls, and external envelope. Steel buildings are used for a variety of purposes including storage, work spaces and living accommodation. They are classified into specific types depending on how they are used.

Steel provides several advantages over other building materials, such as wood:

• Steel is a “green” product; it is structurally sound and manufactured to strict specifications and tolerances. It is also energy efficient. Any excess material is 100% recyclable.

• Steel does not easily warp, buckle, twist or bend, and is therefore easy to modify and offers design flexibility. Steel is also easy to install.

• Steel is cost-effective and rarely fluctuates in price.

• Steel allows for improved quality of construction and less maintenance, while offering improved safety and resistance.

• With the propagation of mold and mildew in residential buildings, using steel minimizes these infestations. Mold needs moist, porous material to grow. Steel studs do not have those problems.

what is wall angle roll forming machine?

A wall angle roll forming machine is a type of industrial equipment used for manufacturing wall angles or corner beads. Wall angles are L-shaped profiles typically made from metal, such as steel or aluminum. They are used in construction to provide structural support and create clean corners between walls and ceilings.

The wall angle roll forming machine is designed to continuously form metal strips into the desired shape of wall angles. It consists of a series of rollers that gradually bend the metal strip, shaping it into the L-shaped profile. The machine may also include additional features such as cutting mechanisms to create precise lengths of wall angles.

The process starts with a metal strip being fed into the machine, which passes through the rollers where it is gradually formed into the desired profile. The rollers exert pressure and bend the metal strip according to the predefined design specifications. Once the strip has been fully formed, it is cut into individual lengths, ready for further use in construction projects.

Wall angle roll forming machines are often automated and controlled by computer systems, ensuring accuracy and efficiency in the manufacturing process. They can produce wall angles in large quantities, offering a cost-effective solution for construction companies or metal fabrication facilities.

function of angle iron roll forming machine

An angle iron roll forming machine is a specialized industrial equipment used for manufacturing angle iron profiles. Angle iron, also known as L-shaped or angle steel, is a structural steel or iron profile with a 90-degree angle.

The primary function of an angle iron roll forming machine is to transform flat metal strips or coils into angle iron profiles with precise dimensions. Here are the key functions and features of an angle iron roll forming machine:

- Material Feeding: The machine is equipped with a material feeding system that accepts metal strips or coils. The material is fed into the machine, typically through a set of rollers, and advanced to the forming section.

- Forming Section: The forming section consists of a series of rollers or roll tooling sets that gradually shape the metal strip into the desired angle iron profile. The rollers apply bending and shaping forces to the material, resulting in the formation of the 90-degree angle.

- Roll Tooling Design: The machine’s roll tooling sets are designed according to the specific dimensions and profile requirements of the angle iron. Different sets of rolls are used to create different angle iron sizes and shapes, such as unequal angles or rounded edges.

- Cutting Mechanism: Once the angle iron profile has been formed, the machine may include a cutting mechanism to cut the formed profile into individual lengths. This ensures precise and consistent dimensions for each angle iron piece.

- Speed and Control: Angle iron roll forming machines are often equipped with adjustable speed controls, allowing operators to set the desired production rate. Computerized control systems monitor and regulate the machine’s functions, ensuring accuracy and efficiency.

- Post-Processing Options: Depending on the specific requirements, an angle iron roll forming machine may have additional features or options. These can include punching holes, embossing patterns, or adding notches to the angle iron profiles.

The overall function of an angle iron roll forming machine is to automate and streamline the manufacturing process of angle iron profiles. By utilizing precise roll tooling and efficient material handling, these machines offer high productivity, consistency, and cost-effectiveness for producing angle iron for various applications in construction, manufacturing, and other industries.

how much does angle roll forming machine?

The cost of an angle roll forming machine can vary significantly depending on several factors, including the machine’s specifications, capabilities, complexity, brand, and the region in which it is purchased. Additionally, the market conditions and fluctuations in raw material costs can also impact the machine’s price.

Generally, angle roll forming machines can range in price from thousands of dollars for smaller, basic models to hundreds of thousands of dollars for larger, high-capacity, and technologically advanced machines.

It’s important to note that the cost of the machine itself is just one aspect of the overall investment. Other factors to consider include shipping or delivery fees, installation and setup costs, training and maintenance expenses, and any additional tooling or accessories required.

To get an accurate and up-to-date price for an angle roll forming machine, it is recommended to contact specific manufacturers or suppliers that specialize in roll forming machinery. They can provide you with detailed information about their products, pricing, and any customization options available to suit your specific needs.

What Is An Angle Roll Forming Machine And Why Would You Want One?

Reviews

There are no reviews yet.