Что такое машина для производства металлических жалюзи?

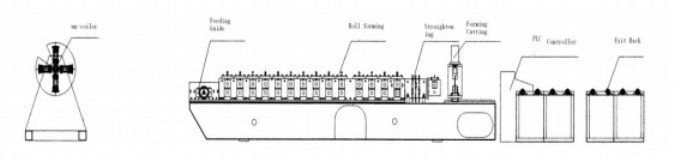

Профилегибочная машина для металлических жалюзи представляет собой специализированное оборудование, предназначенное для производства профилегибочных машин для металлических ставней. В нем используется передовая технология профилирования для придания металлическим листам нужного профиля для рулонных ворот. Машина обычно включает в себя разматыватель для подачи металлического листа, роликоформирующий станок с рядом роликов, которые постепенно придают металлу форму, и резак для резки металла до нужной длины.

Наше профилегибочное оборудование для производства металлических жалюзи спроектировано с учетом точности и эффективности, что позволяет производить продукцию высокого качества в короткие сроки. Он оснащен передовыми системами управления для обеспечения точности и постоянства процесса формования. В результате получаются прочные и долговечные рулонные ворота, обеспечивающие безопасность, изоляцию и другие преимущества для коммерческого и промышленного применения.

Наше профилегибочное оборудование для производства металлических жалюзи может работать с металлическими листами различной толщины и ширины, что делает его очень универсальным и адаптируемым к различным производственным потребностям. Кроме того, мы предлагаем варианты настройки, чтобы адаптировать машину к конкретным требованиям, обеспечивая оптимальную производительность и производительность.

Как работает профилегибочная машина для жалюзи?

Профилегибочная машина для жалюзийных дверей непрерывно изгибает и формирует длинную металлическую полосу в желаемый профиль жалюзийной двери. Вот пошаговое объяснение того, как обычно работает машина:

- Подача материала: металлическая полоса, обычно в виде рулона, загружается на разматыватель в начале линии профилирования. Разматыватель разматывает полосу, позволяя ей плавно проходить через машину.

- Направление и выравнивание: полоса проходит через серию направляющих и выравнивающих устройств, чтобы гарантировать, что она остается в правильном положении и правильно выровнена, когда она входит в секцию профилирования.

- Профилегибочная секция: Сердцем машины является секция профилирования. Эта секция состоит из ряда роликов, которые стратегически расположены таким образом, чтобы постепенно формировать металлическую полосу. Каждый набор роликов выполняет определенную операцию гибки, постепенно превращая полосу в желаемый профиль двери-жалюзи. Ролики обычно приводятся в действие электродвигателями и могут регулироваться для достижения точных размеров и требуемых форм.

- Резка: после того, как металлическая полоса полностью сформирована, используется режущий механизм, чтобы отделить сформированные двери жалюзи от оставшейся полосы. Это можно сделать с помощью различных методов резки, таких как резка, штамповка или распиловка, в зависимости от конкретной конструкции и требований.

- Дополнительные операции: В зависимости от конструкции и технических характеристик жалюзийной двери машина может включать дополнительные станции для выполнения таких операций, как пробивка отверстий, тиснение узоров или логотипов, добавление замков или петель, а также нанесение защитных покрытий или отделки. Эти станции часто интегрированы в линию профилирования, что обеспечивает непрерывный и автоматизированный производственный процесс.

- Сбор и штабелирование: после того, как жалюзийные двери были вырезаны и выполнены все дополнительные операции, они собираются и складываются для дальнейшей обработки или упаковки. Это можно сделать с помощью автоматизированных систем или вручную, в зависимости от размера и веса готовой продукции.

На протяжении всего процесса машина обычно управляется компьютеризированной системой, которая обеспечивает точное и постоянное формирование металлической полосы. Датчики и механизмы обратной связи могут использоваться для контроля параметров производства и внесения необходимых корректировок для поддержания точности и качества.

Используя профилегибочную машину для производства ставней, производители могут эффективно производить высококачественные ставни различных размеров и конструкций, удовлетворяя особые потребности своих клиентов.

Технические данные машины для производства металлических рулонных жалюзи

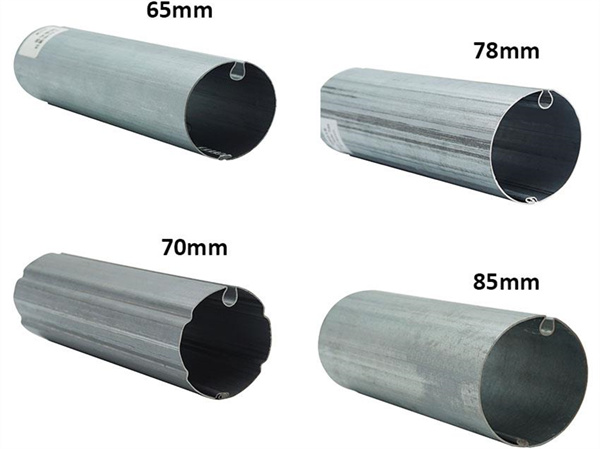

- Материалы для изготовления металлических рулонных ворот. Машина: оцинкованные рулоны 0,7-1,2 мм. Ширина подачи: 184 мм.

- Шаги формирования: около 12 шагов

- Материал роликов: сталь GCr15 прецизионной высокочастотной закалки HRC58-62 диаметр роликов: 150

- Материал главного вала: высококачественная сталь 45#.

- Материал цепи: сталь 45# высокочастотной закалки, круговой шаг: 38,1 количество зубьев: 13

- Резка: гидравлическая резка с закалкой HRC58-62

- Электронное управление: управление ПЛК Panasonic Brand

- Размер машины: 4500ммX500ммX800мм

- Рабочая скорость: 12-15 м/мин.

- Система привода: цепной привод

- Мощность главного двигателя: 7,5 кВт

Профилегибочная машина для металлических рулонных ворот предназначена для формирования рулонов оцинкованного металла толщиной от 0,7 до 1,2 мм в рулонные ворота. Ширина подачи металлического листа составляет 184 мм, и машина имеет около 12 шагов формовки.

Валки станка изготовлены из стали GCr15 и прошли прецизионную обработку с высокочастотной закалкой, что обеспечивает твердость HRC58-62. Диаметр роликов составляет 150 мм, что обеспечивает эффективную и равномерную формовку.

Главный вал машины изготовлен из высококачественной стали 451ТП5Т, а материал цепи – из стали 451ТП5Т, прошедшей высокочастотную закалку. Круговой шаг цепи 38,1, а количество зубьев 13, что обеспечивает плавную и стабильную работу.

Станок оснащен гидравлической системой резки, прошедшей закалку с твердостью HRC58-62, что обеспечивает эффективную и точную резку. Электронная система управления представляет собой ПЛК от известного бренда Panasonic.

Размеры машины составляют 4500 мм X 500 мм X 800 мм, а рабочая скорость составляет 12-15 м/мин. Система привода - цепная передача, обеспечивающая надежную и эффективную передачу мощности. Мощность основного двигателя машины составляет 7,5 кВт, что делает ее мощной и функциональной машиной для производства рулонных ворот.

Мы стремимся предоставить нашим покупателям подробную и точную информацию о нашей машине для производства металлических рулонных ставней, и мы приветствуем любые дополнительные вопросы или запросы.

Рабочий поток машины для производства металлических рулонных жалюзи

Разматыватель—→устройство выравнивания—→основной профилегибочный станок—→ гидравлическая резка—→ выходной стол

Рабочий процесс машины для производства металлических рулонных жалюзи можно описать следующим образом:

- Размотка: Рулон металла загружается на разматыватель и разматывается, обеспечивая непрерывную подачу материала для машины.

- Направление и подача: металлический лист направляется и подается в профилегибочную машину через ряд роликов, которые придают ему желаемый профиль.

- Профилирование: металлический лист пропускается через ряд роликов, которые постепенно придают ему желаемый профиль для рулонных ворот. Форма роликов определяет окончательную форму металлического листа, и машина может иметь несколько наборов роликов для создания сложных профилей или для обработки металлических листов различной ширины.

- Резка: Фасонный металлический лист режется на нужную длину с помощью гидравлической системы резки, которая прошла закалку с твердостью HRC58-62, что обеспечивает эффективную и точную резку.

- Сбор: Готовое изделие, рулонные ворота с прочным и долговечным металлическим профилем, собирается в конце машины.

На протяжении всего процесса усовершенствованные системы управления станка контролируют и регулируют скорость и давление роликов и режущего инструмента, чтобы обеспечить точность и постоянство процесса формования.

Части машины для производства металлических рулонных жалюзи

| Имя | Количество (набор) |

| Разматыватель | 1 комплект |

| Устройство уровня | 1 комплект |

| Гидравлическая машина для резки | 1 комплект |

| Основная профилегибочная машина | 1 комплект |

| Выполнить стол | 2 комплекта |

| Панель управления | 1 комплект |

Профилегибочная машина для производства металлических рулонных ворот состоит из следующих частей:

- Разматыватель: это первый компонент машины, который используется для удержания рулона металла, который будет подаваться в профилегибочную машину.

- Устройство выравнивания: Это устройство используется для обеспечения ровности и прямолинейности металлического листа перед его подачей в профилегибочную машину. Это помогает предотвратить любое искажение или изгиб конечного продукта.

- Гидравлический отрезной станок: этот компонент станка используется для резки металлического листа до нужной длины после того, как он был сформирован в нужный профиль на профилегибочном станке.

- Профилегибочная машина для основного профиля: это основной компонент машины, который отвечает за постепенное придание металлическому листу желаемого профиля для рулонных ворот. Обычно он включает в себя ряд роликов, которые изгибают и формируют металлический лист по мере его прохождения.

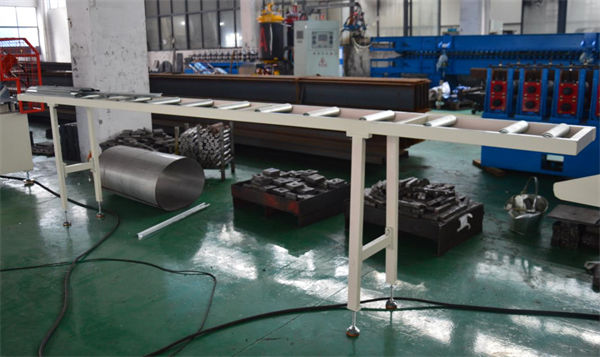

- Выходной стол: этот компонент машины обеспечивает поддержку готового продукта на выходе из профилегибочной машины. Обычно он состоит из двух наборов столов, которые помогают гарантировать, что готовый продукт останется ровным и прямым.

- Панель управления: Этот компонент машины используется для контроля и мониторинга работы всей системы. Обычно он включает в себя систему управления ПЛК от известного бренда, такого как Panasonic.

В целом, наша машина для производства металлических рулонных ставней представляет собой сложную систему, которая включает в себя несколько ключевых компонентов, каждый из которых играет решающую роль в общей работе машины. Работая вместе, эти компоненты позволяют эффективно и точно производить высококачественные рулонные ворота из металла.

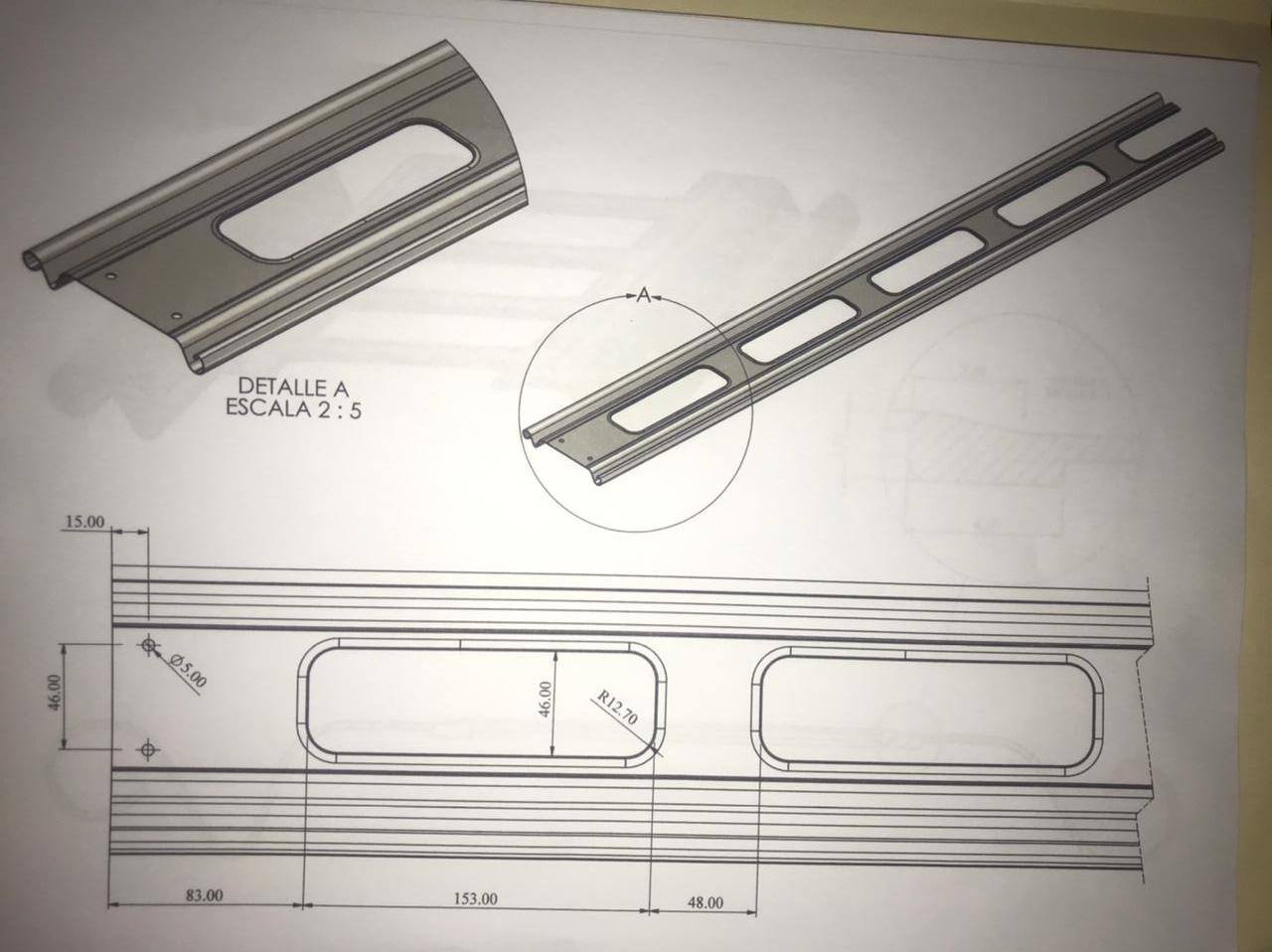

Чертеж профиля машины для производства рулонных ворот из металла

Применение профилегибочной машины для производства металлических жалюзи

Профилегибочная машина для металлических ставней представляет собой универсальное оборудование, широко используемое в обрабатывающей промышленности для производства ворот из металла. Эти двери имеют множество применений, в том числе обеспечивают прочный и долговечный барьер против несанкционированного доступа в коммерческих и промышленных помещениях, таких как витрины, склады, фабрики и гаражи.

Рулонные ворота также обеспечивают дополнительный уровень безопасности и защиты от краж, вандализма и стихийных бедствий, таких как штормы и ураганы. Они могут быть изолированы для обеспечения теплоизоляции, снижения затрат на энергию для зданий, требующих контроля температуры, таких как склады для пищевых продуктов или холодильные камеры. Кроме того, рольставни могут снизить уровень шума в зданиях, расположенных в шумных местах, например, вблизи аэропортов или автомагистралей.

Наше профилегибочное оборудование для производства металлических жалюзи отличается высокой универсальностью и может производить различные профили роллетных дверей, в том числе с изоляцией или другими специальными характеристиками. Он оснащен передовыми системами управления для обеспечения точности и постоянства процесса формования, в результате чего получается высококачественная продукция, отвечающая потребностям различных клиентов.

Подробная информация о каждой машине для производства металлических рулонных жалюзи

1.3 тонны пассивный разматыватель

- Пассивный разматыватель 3 тонны

- Внутренний диаметр катушки: ¢460-520 мм

Машина поставляется с 1,3-тонным или 3-тонным пассивным разматывателем, который используется для удержания рулона металла, который будет подаваться в профилегибочную машину. Внутренний диаметр катушки должен быть в пределах ¢460-520 мм.

2. Устройство уровня

Устройство уровня используется для обеспечения того, чтобы металлический лист был ровным и прямым перед его подачей в профилегибочную машину. Это помогает предотвратить любое искажение или изгиб конечного продукта.

3. Гидравлическая резка

- Резка после формовки: Разрежьте лист после формовки на необходимую длину.

- Движение резки: основная машина автоматически останавливается, и начинается резка. После резки основная машина запустится автоматически.

- Материал лезвия: CR12mov с термообработкой

- Измерение длины: Автоматическое измерение длины

- Допустимое отклонение длины: 10 м +/- 2 мм

Гидравлическая система резки отвечает за обрезку металлического листа до нужной длины после того, как он был сформирован в нужный профиль на профилегибочном станке. Движение резки автоматическое и происходит после остановки основного станка. Клинок изготовлен из CR12мов с термообработкой. Длина измеряется автоматически, допуск на длину составляет 10 м +/- 2 мм.

4. Внешний стол

- Длина: 6 метров

- Количество: 1 шт.

Выходной стол поддерживает готовый продукт на выходе из профилегибочной машины. Длина 6 метров, и есть одна единица.

5. Блок управления: торговая марка Delta

- Источник питания: 380 В, 50 Гц, 3 фазы (регулируется по запросу)

- Автоматическое измерение длины и количества;

- Длина и количество контролируются ПЛК,

- Неточность длины можно легко исправить.

- Панель управления: кнопочный переключатель и сенсорный экран

- Язык сенсорного экрана: английский и китайский.

- Единица длины: миллиметр (включается на панели управления)

Блок управления отвечает за контроль и мониторинг работы всей системы. Он оснащен источником питания марки Delta, который настраивается в соответствии с требуемыми характеристиками. Длина и количество автоматически измеряются и контролируются системой ПЛК, а погрешность длины может быть легко изменена. Панель управления включает в себя кнопочный переключатель и сенсорный экран, а язык на сенсорном экране можно переключать между английским и китайским языками. Единицей длины являются миллиметры.

В целом, наша машина для производства металлических рулонных ставней представляет собой сложную систему, которая включает в себя несколько ключевых компонентов, каждый из которых играет решающую роль в общей работе машины. Работая вместе, эти компоненты позволяют эффективно и точно производить высококачественные рулонные ворота из металла.

5 лучших производителей рулонных профилегибочных машин в Китае

- Sussman Machinery(Wuxi)Co., Ltd. экспортирует свою продукцию в более чем 100 стран, и наши клиенты находятся по всему миру, особенно в Австралии, Южной Америке, Европе, Индии, на Ближнем Востоке, в Северной Европе и Северной Африке. Кроме того, мы хотим создать лучшую машину для клиентов, нашими основными ценностями являются «Качество, эффективность, надежность и честность», которые могут твердо и твердо поддерживать нас, чтобы идти далеко.

- Hangzhou Zhongyuan Machinery Factory: производит профилегибочные машины с 2003 года и предлагает широкий спектр оборудования, включая профилегибочные машины для ставней и дверей.

- Liming Stamping Form Machine Co., Ltd. Обладая более чем 20-летним опытом, компания Liming является авторитетным производителем, специализирующимся на профилегибочных машинах, в том числе для изготовления жалюзийных дверей.

- Botou Golden Integrity Roll Forming Machine Co., Ltd: Компания Golden Integrity, основанная в 1993 году, является известным производителем профилегибочных машин, в том числе для изготовления жалюзийных дверей, уделяя особое внимание качеству и удовлетворенности клиентов.

- Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd: Компания производит профилегибочные машины уже более 20 лет и предлагает широкий спектр машин, в том числе профилегибочные машины для ставней и дверей.

Отзывы

Отзывов пока нет.