When it comes to the construction industry, time is money – and the purlin roll forming machine allows you to save both! This blog article discusses how this machine can allow your company to save time and increase efficiency.

Introduction

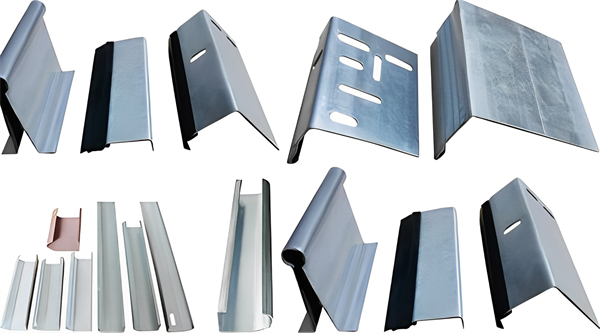

The purlin roll forming machine is a time-saving and efficient way to produce metal sheet products. The machine has a number of features that make it an ideal choice for producing metal sheet products, such as its ease of use and its ability to cut production time by up to 50%.

The purlin roll forming machine is made up of several parts that are linked together by a mechanism. This mechanism allows the machine to move the metal sheets from one end to the other, forming them into the desired shape. The machine can also be programmed to automatically cut the metal sheets into the appropriate size.

This type of machine is ideal for producing metal sheet products, such as roofing panels, car parts, and agricultural equipment. It can save you time by cutting production time by up to 50% and increasing efficiency by allowing you to create products with precision accuracy.

Purlin Roll Forming Machine History

The Purlin Roll Forming Machine is a machine that cuts time and increases efficiency in the production of steel rolls. The machine uses roll forming to create steel plates or coils. It was first developed in the 1950s by Raymond Loewy, who was looking for a more efficient way to produce steel rolls.

The Purlin Roll Forming Machine is made up of several parts: the die, the mandrel, the press brake, and the motor. The die is a v-shaped piece of metal that forms the steel plate or coil. The mandrel is a round piece of metal that sits inside of the die and helps to shape the steel plate or coil. The press brake applies pressure to the steel plate or coil as it is being formed, which helps to keep it together and prevent it from stretching. The motor powers the press brake, and allows you to make different sizes and shapes of steel plates or coils.

-

Garage door panel roll forming machine

Garage door panel roll forming machine -

Green modern Agriculture gutter panel roll forming machine with tank chain

Green modern Agriculture gutter panel roll forming machine with tank chain -

Roll forming machine China for Automatically PPGI Fence Panel

Roll forming machine China for Automatically PPGI Fence Panel -

Roll forming machine company for Fence guide Rail

Roll forming machine company for Fence guide Rail -

Roll forming machine cost for Fence post guide rail good price

Roll forming machine cost for Fence post guide rail good price -

Stainless U Channel for Glass Window Supporter Machine

Stainless U Channel for Glass Window Supporter Machine -

Shutters Box Series Forming Machines

Shutters Box Series Forming Machines -

Awning Tube Roll forming machine

Awning Tube Roll forming machine -

Metal door frame roll forming machine Double rebate

Metal door frame roll forming machine Double rebate

How Does the Purlin Roll Forming Machine Work?

The purlin roll forming machine is a unique and efficient way to create custom-shaped fabric products. It works by cutting fabric sheets into small, uniform rolls using a rotating blade. This makes it a faster and more accurate way to produce products than traditional methods such as sewing or knitting.

The machine has two main sections: the presser bar and the blade. The presser bar is where the fabric is laid down and the blade cuts it into small rolls. The blade moves in a circular pattern and can cut through several layers of fabric at once. This makes it very fast and efficient, which is why it’s so popular for manufacturing custom-sized fabrics.

The purlin roll forming machine also has some other advantages over other methods of manufacturing fabric products. For example, it doesn’t require any special tools or machines, which means that it can be used by anyone with basic sewing skills. Additionally, it can be moved around easily, which allows you to use it in multiple locations without having to invest in expensive equipment or facilities. This makes it an ideal choice for businesses that need to quickly produce large quantities of custom-sized fabric products.

How to cut Time and Increase Efficiency with purlin roll forming machine?

The purlin roll forming machine is a cutting-edge device that efficiently forms rolls of PURLIN fabric. The machine uses a number of cutting and shaping mechanisms to quickly form the purlins, which are essential in the production of textile products.

The purlin roll forming machine is designed to speed up the production process by forming rolls of PURLIN fabric quickly and accurately. It features several cutting and shaping mechanisms that allow for quick and accurate creation of the purlins. The result is increased efficiency and time savings for your business.

Advantages of a purlin roll forming machine

Purlin rolls form high-quality plastic parts with accurate tolerances and repeatable shapes. Advantages of using a purlin roll forming machine include:

- Reduced manufacturing time: Purlin rolls can be formed quickly and easily, eliminating the need for skilled labor.

- Precise tolerances: Purlin rolls produce parts with accurate tolerances, ensuring that the finished product meets your specifications.

- Fine details: With a purlin roll forming machine, you can create delicate or intricate details in your parts, without having to use separate machines for each step.

Conclusion

Purlin rolls are a valuable tool in the metalworking arsenal, and with good reason. They can be used to form almost any shape you could dream up, quickly and easily. However, like most things in life, there is always room for improvement. By using a purlin roll forming machine, you can cut down on your time spent forming parts by leaps and bounds. Not to mention, this type of machine is incredibly efficient, meaning that you’ll be able to produce more parts in less time than ever before. If you’re looking for an edge on your competition, get yourself a purlin roll forming machine today!