परिचय

Imagine driving down a highway, enjoying the scenery, confident that you’re protected in case of an unexpected swerve or mishap. This sense of security largely stems from the unsung heroes of road safety: highway guardrails. These seemingly simple metal barriers play a vital role in preventing vehicles from straying off the road and mitigating the severity of accidents. But how are these ubiquitous guardrails actually made? Enter the highway guardrail forming machine, a marvel of engineering that efficiently shapes metal coils into the distinctive guardrail profiles we see lining our roads.

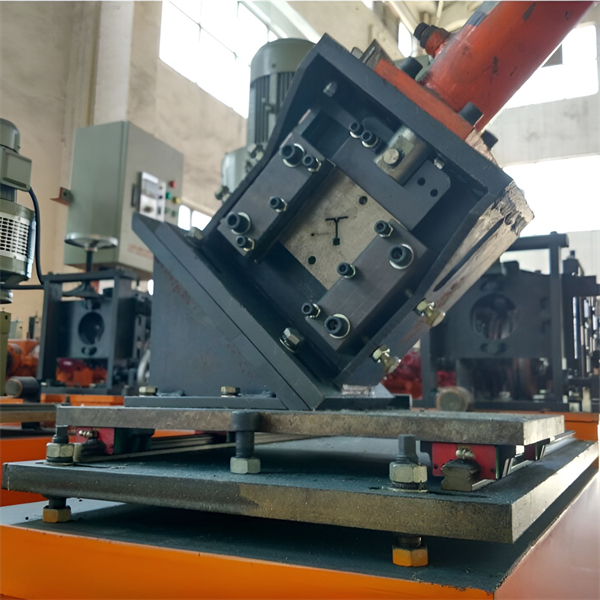

Understanding the Machine

Specifications of Highway Guardrail Forming Machine:

| Feature | विवरण |

|---|---|

| Material | High-strength steel |

| Power Source | Electric motor (typically ranging from 30 kW to 100 kW) |

| बनाने की गति | 5 – 10 meters per minute |

| Roll Forming Stations | 8 – 14 stations (depending on guardrail profile complexity) |

| नियंत्रण प्रणाली | PLC (Programmable Logic Controller) for automated operation |

| Dimensions (L x W x H) | Varies depending on the manufacturer and machine capacity, typically ranging from 8 meters to 15 meters in length, 2 meters to 3 meters in width, and 2 meters to 3 meters in height. |

| वज़न | 15,000 kg to 30,000 kg |

Operation Process of Highway Guardrail Forming Machine

- Coil Loading: A metal coil, typically made of high-strength steel with a thickness ranging from 2.0 mm to 4.0 mm, is loaded onto the uncoiler at the beginning of the machine.

- Straightening: The metal sheet is fed through a series of rollers that straighten any bends or unevenness from the coil.

- Roll Forming: The straightened sheet enters the heart of the machine – the roll forming stations. Each station comprises a set of precisely shaped rollers that progressively bend the metal sheet into the desired guardrail profile. The number of stations and their specific configurations determine the final shape of the guardrail.

- Punching and Shearing: Depending on the specific guardrail design, the machine may incorporate additional stations for punching holes for fasteners or shearing the formed profile to the desired length.

- Stacking or Coiling: The finished guardrail sections are either automatically stacked on a pallet or recoiled for further processing or transportation.

Types of Highway Guardrail Forming Machine

Highway guardrail forming machines play a crucial role in ensuring road safety by producing the metal barriers that line our highways. These machines are capable of manufacturing various types of guardrail boards, each with its own unique properties and applications.

The Workhorse: W-Beam Guardrail

The most widespread type of guardrail is the W-beam guardrail. As its name suggests, it boasts a distinctive corrugated “W” shape. This design offers a golden ratio of strength, flexibility, and cost-effectiveness. The W-beam’s flexibility allows it to absorb impact and redirect vehicles safely, while its corrugated shape provides added strength to withstand significant forces. Additionally, its simple design makes it relatively inexpensive to produce, making it a popular choice for various road applications.

Enhanced Strength: Thrie-Beam Guardrail

For situations demanding even greater strength, the thrie-beam guardrail comes into play. This type features a unique three-wave profile, offering superior strength compared to its W-beam counterpart. This enhanced sturdiness makes it well-suited for high-risk areas like median barriers, where it can effectively separate opposing traffic and prevent head-on collisions.

Aesthetics Meet Strength: Box-Beam Guardrail

If both strength and aesthetics are priorities, the box-beam guardrail takes the stage. As its name implies, this guardrail has a closed box-like shape, providing increased rigidity compared to other types. This design not only enhances its ability to withstand impacts but also creates a visually pleasing and modern aesthetic, making it a suitable choice for areas where appearance matters, such as around bridges or urban environments.

-

गेराज दरवाजा पैनल रोल बनाने की मशीन

गेराज दरवाजा पैनल रोल बनाने की मशीन -

चैनल प्रकार ट्रंकिंग केबल ट्रे मशीन

चैनल प्रकार ट्रंकिंग केबल ट्रे मशीन -

वी स्ट्रट रोल बनाने की मशीन

वी स्ट्रट रोल बनाने की मशीन -

फायर डम्पर ब्लेड रोल बनाने की मशीन

फायर डम्पर ब्लेड रोल बनाने की मशीन -

उपकरण ब्रैकेट सी स्ट्रट रोल बनाने की मशीन

उपकरण ब्रैकेट सी स्ट्रट रोल बनाने की मशीन -

ग्लास विंडो सपोर्टर मशीन के लिए स्टेनलेस यू चैनल

ग्लास विंडो सपोर्टर मशीन के लिए स्टेनलेस यू चैनल -

शटर बॉक्स सीरीज बनाने की मशीन

शटर बॉक्स सीरीज बनाने की मशीन -

शामियाना ट्यूब रोल बनाने की मशीन

शामियाना ट्यूब रोल बनाने की मशीन -

धातु दरवाजा फ्रेम रोल बनाने की मशीन डबल छूट

धातु दरवाजा फ्रेम रोल बनाने की मशीन डबल छूट

Advantages and Considerations:

लाभ

- High Efficiency: Highway guardrail forming machines can produce large quantities of guardrail profiles at a rapid pace, significantly reducing production time and costs compared to manual methods.

- Consistency and Accuracy: The use of precisely designed rollers ensures consistent and accurate shaping of guardrails, meeting strict quality and safety standards.

- Versatility: Modern machines can be configured to produce various guardrail profiles, catering to diverse project requirements.

- Reduced Labor Costs: The automated operation of the machine minimizes the need for manual labor, leading to cost savings and improved safety for workers.

Considerations

- Initial Investment: The initial cost of purchasing a highway guardrail forming machine can be substantial, requiring careful planning and justification based on production volume and project needs.

- Maintenance: Regular maintenance and replacement of worn-out parts are crucial to ensure the smooth operation and accuracy of the machine.

- Technical Expertise: Operating and maintaining a complex machine like a guardrail forming machine requires skilled personnel with a good understanding of its mechanics and functionalities.

अनुप्रयोग

Highway guardrail forming machines play a crucial role in the production of guardrails used in various applications:

- Segregating Traffic Lanes: Guardrails act as physical dividers between opposing lanes of traffic, preventing head-on collisions and promoting orderly traffic flow. This is especially important on high-speed highways where even a minor miscalculation can have catastrophic consequences.

- Preventing Median Crossovers: Guardrails form a barrier between the main roadway and the median, preventing vehicles from losing control and crossing into oncoming traffic. This is crucial for maintaining lane discipline and reducing the risk of multi-vehicle accidents.

- Safeguarding Pedestrians and Cyclists: Guardrails serve as a protective shield for pedestrians and cyclists using designated pathways alongside roads. They prevent accidental straying onto the main traffic lanes and offer additional safety in case of a vehicle losing control.

- Enhancing Bridge and Overpass Safety: Guardrails on bridges and overpasses provide an extra layer of security, preventing vehicles from veering off the elevated structures. This is particularly important for bridges with narrow lanes or sharp curves, where a misstep could have severe consequences.

Choosing the Right Machine

Selecting the appropriate highway guardrail forming machine is a crucial decision for manufacturers, requiring careful consideration of several factors:

- Production Volume: The anticipated production volume significantly impacts the choice. High-volume production facilities may benefit from investing in a machine with a faster forming speed and higher capacity, while lower-volume operations might opt for a more cost-effective model.

- Guardrail Profile Complexity: The complexity of the desired guardrail profile influences the machine’s specifications. Simpler profiles like W-beams can be produced on machines with fewer roll forming stations, while intricate profiles like box-beams might necessitate machines with a higher station count and potentially more complex roller configurations.

- Level of Automation: The degree of automation desired plays a role in selecting the machine. Basic models might require manual intervention for tasks like loading and unloading, while advanced machines offer fully automated operation, improving efficiency and safety.

- Budget: The initial investment cost, along with ongoing maintenance expenses, needs to be factored into the decision-making process. Finding the right balance between affordability and capabilities is crucial.

Market Landscape and Leading Manufacturers

The global highway guardrail forming machine market is expected to witness steady growth, driven by increasing investments in road infrastructure development, particularly in emerging economies. Some of the prominent players in the market include:

- Sussman (China)

- Formetal Technology Group (China)

- Volkmar Group (Germany)

- A.M.C. Equipment & Machinery (Italy)

- Dayton Superior (United States)

These manufacturers offer a diverse range of machines catering to various production needs and guardrail profile requirements.

The Future of Highway Guardrail Forming Machines

As technology continues to evolve, we can expect advancements in highway guardrail forming machines in several areas:

- Increased Automation: The level of automation is likely to rise, with features like automatic coil loading and unloading, defect detection, and self-diagnosis becoming more commonplace.

- Integration with Industry 4.0: The machines might be integrated with Industry 4.0 technologies, enabling real-time monitoring, remote diagnostics, and predictive maintenance capabilities.

- Sustainable Materials and Processes: Growing environmental concerns might lead to the development of machines that utilize eco-friendly materials in their construction and incorporate energy-efficient operation features.

निष्कर्ष

Highway guardrail forming machines serve as the backbone of road safety infrastructure production. By understanding their functionalities, capabilities, and selection considerations, manufacturers can make informed decisions to optimize their guardrail production processes. As the industry progresses, we can expect these machines to become even more sophisticated, automated, and sustainable, contributing to the construction of safer and more resilient roadways.

सामान्य प्रश्न

Q: What is the typical lifespan of a highway guardrail forming machine?

A: The lifespan of a highway guardrail forming machine can vary depending on various factors like maintenance practices, usage frequency, and overall quality. However, well-maintained machines can last for 15 to 20 years or even longer.

Q: What safety precautions should be taken when operating a highway guardrail forming machine?

A: Operating any industrial machinery requires adherence to safety protocols. Here are some essential safety precautions for using a highway guardrail forming machine:

- Always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and ear protection.

- Ensure proper training and authorization for operating the machine.

- Follow the manufacturer’s instructions for safe operation and maintenance procedures.

- Be mindful of pinch points and moving parts while the machine is operational.

- Regularly inspect the machine for any signs of wear or damage and report them immediately for repair.

Q: How much does a highway guardrail forming machine cost?

A: The cost of a highway guardrail forming machine can vary significantly depending on its features, capabilities, and brand. The price range typically falls between $50,000 and $200,000.