Imagine a colossal cylinder rising from the plains, a silent sentinel safeguarding a wealth of resources. This is the steel silo, a ubiquitous workhorse in countless industries. But before these giants stand tall, they need to be born. Enter the steel silo machine, the unsung hero responsible for shaping the metal sheets into these dependable storage solutions.

Function of Steel Silo Machines

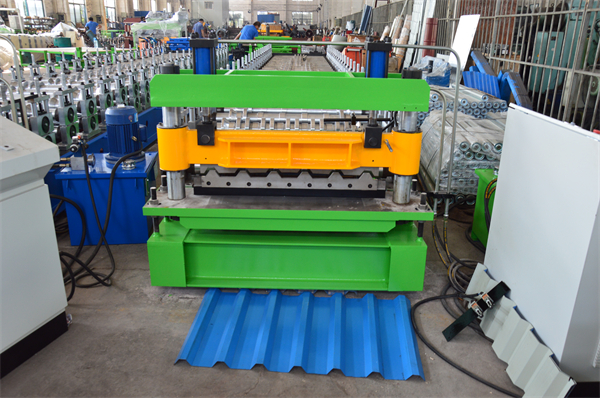

Steel silo machines are marvels of metal manipulation. Their primary function is to transform large sheets of steel into the curved panels that form the core structure of a silo. This process, known as roll forming, involves feeding the steel sheets through a series of precisely designed rollers that progressively bend and shape the metal into the desired profile. Imagine a giant cookie cutter, but instead of sweet treats, it crafts the building blocks for industrial storage.

Types of Steel Silo Machines

The world of steel silo machines isn’t a one-size-fits-all affair. Different machines cater to the specific needs of silo construction:

- Silo Corrugated Panel Roll Forming Machine: This is the workhorse, responsible for creating the corrugated steel panels that form the silo’s outer shell. The corrugations, those wavy ridges, add strength and rigidity to the structure, allowing it to withstand significant weight and external pressure.

- Corrugated Plate Punch Press: While the roll forming machine shapes the steel, the punch press comes into play for creating holes and cutouts in the panels. These openings are crucial for silo access doors, ventilation systems, and attachment points for additional equipment.

- Corrugated Plate Bender: As the name suggests, this machine bends pre-formed silo panels to specific angles. This is particularly important for constructing the silo’s conical roof, which allows for efficient material flow and prevents rain or snow accumulation.

Applications of Steel Silo Machines

Steel silos are the storage champions across various industries. Here’s where these metal giants come into play:

- Agriculture: Grain, seeds, and other dry bulk agricultural products find a safe haven in steel silos. Their weatherproof design protects harvests from the elements, while the smooth interior walls ensure minimal product clinging, maximizing storage capacity.

- Food & Beverage: From flour and sugar to coffee beans and malt, steel silos play a vital role in the food and beverage industry. Their ability to maintain consistent temperatures and prevent contamination safeguards the integrity of these valuable products.

- Construction: Cement, sand, and other construction materials are efficiently stored in steel silos. The robust design ensures these heavy materials are safeguarded from weather damage, while easy access points facilitate quick retrieval for ongoing projects.

- Chemical & Plastics: Steel silos provide secure storage for various chemicals, plastics, and other industrial materials. Their ability to be customized for specific needs, including temperature control and specialized linings, makes them a versatile storage solution.

Advantages of Steel Silo Machines

There’s a reason steel silo machines are the go-to choice for industrial storage. Here’s a breakdown of their key benefits:

- Efficiency: Compared to traditional silo construction methods, steel silo machines offer a faster and more streamlined process. The automated roll forming and bending ensure consistent quality and reduce reliance on manual labor.

- Durability: The steel silos produced by these machines are built to last. The galvanized steel construction offers excellent resistance to corrosion and harsh weather conditions, guaranteeing a long service life.

- Versatility: Steel silo machines can be adapted to create silos in various sizes and configurations. This allows for customization based on specific storage needs and available space.

- Cost-Effectiveness: While the initial investment might seem substantial, steel silo machines offer a cost-effective solution in the long run. Their durability minimizes replacement needs, and the efficient construction process translates to lower labor costs.

-

वेल्ड पाइप रोल बनाने की मशीन

वेल्ड पाइप रोल बनाने की मशीन -

गेराज दरवाजा पैनल रोल बनाने की मशीन

गेराज दरवाजा पैनल रोल बनाने की मशीन -

टैंक श्रृंखला के साथ ग्रीन आधुनिक कृषि गटर पैनल रोल बनाने की मशीन

टैंक श्रृंखला के साथ ग्रीन आधुनिक कृषि गटर पैनल रोल बनाने की मशीन -

स्वचालित रूप से PPGI बाड़ पैनल के लिए रोल बनाने की मशीन चीन

स्वचालित रूप से PPGI बाड़ पैनल के लिए रोल बनाने की मशीन चीन -

बाड़ गाइड रेल के लिए रोल बनाने की मशीन कंपनी

बाड़ गाइड रेल के लिए रोल बनाने की मशीन कंपनी -

बाड़ पोस्ट गाइड रेल अच्छी कीमत के लिए रोल बनाने की मशीन की लागत

बाड़ पोस्ट गाइड रेल अच्छी कीमत के लिए रोल बनाने की मशीन की लागत -

कट टू लेंथ लाइन

कट टू लेंथ लाइन -

वी स्ट्रट रोल बनाने की मशीन

वी स्ट्रट रोल बनाने की मशीन -

शटर बॉक्स सीरीज बनाने की मशीन

शटर बॉक्स सीरीज बनाने की मशीन

Disadvantages of Steel Silo Machines

It’s important to consider all aspects before diving headfirst. Here are some potential drawbacks of steel silo machines:

- Initial Investment: The upfront cost of a steel silo machine can be significant, especially for larger or more complex models. This might be a hurdle for smaller businesses with limited budgets.

- Skill Requirement: Operating a steel silo machine requires a certain level of skill and training. Improper use can lead to production delays or even damage to the machine or the silo panels.

- Storage Limitations: While steel silos excel at storing dry bulk materials, they might not be suitable for all products. Liquids or materials requiring specific temperature or humidity control might necessitate alternative storage solutions.

Choosing the Right Steel Silo Machine

Selecting the perfect steel silo machine hinges on several factors. Consider these key questions:

- What type of silo do you need to construct? Grain storage will require different specifications compared to a silo for storing chemicals.

- What is your desired silo size? Machine capabilities vary, so ensure the chosen model can handle the dimensions of your planned silo.

- What is your budget? Compare the cost of different machines while factoring in factors like operating costs and potential maintenance needs.

- What level of automation do you require? Some machines offer a higher degree of automation, minimizing manual intervention. This can be beneficial for high-volume production but might come at a premium price.

Leading Suppliers of Steel Silo Machines

The market boasts a range of steel silo machine manufacturers, each with its strengths and specialties. Here’s a glimpse into some prominent players:

- Lipton Machinery (China): Renowned for their high-capacity and user-friendly silo roll forming machines, Lipton offers solutions for various silo sizes and applications.

- SiroSilo (Italy): Specializing in innovative silo construction equipment, SiroSilo’s machines are known for their precision and efficiency.

- Yongsan Silo Machine (South Korea): A leading name in Asia, Yongsan offers a comprehensive range of silo machines, from basic roll forming equipment to complete silo production lines.

- AGRO-AVIS (Poland): This European manufacturer focuses on machines specifically designed for agricultural applications, ensuring optimal performance for grain storage needs.

- Westberg Silo (United States): While not solely focused on machine manufacturing, Westberg Silo is a valued resource for North American customers, offering silo machines alongside expert consultation and silo component supplies.

Pricing Considerations for Steel Silo Machines

The cost of a steel silo machine depends on several factors, including:

- Machine capabilities: Machines capable of handling larger or more complex silo designs will naturally carry a higher price tag.

- Level of automation: Fully automated machines offer greater efficiency but come at a premium compared to semi-automated or manual models.

- Brand reputation: Established brands with a proven track record might command a higher price compared to lesser-known manufacturers.

Here’s a ballpark range to consider (prices may vary depending on supplier and currency fluctuations):

- Basic silo roll forming machine: $20,000 – $50,000 USD

- Mid-range machine with additional features: $50,000 – $100,000 USD

- High-end, fully automated machine: $100,000+ USD

It’s crucial to remember that these are just starting points. Obtaining quotes directly from manufacturers with your specific requirements will provide the most accurate pricing information.

Advanced Features of Steel Silo Machines

The world of steel silo machines isn’t limited to basic roll forming. Advanced features can further enhance the efficiency and capabilities of these machines:

- Computerized controls: These allow for precise control over the roll forming process, ensuring consistent panel quality and minimizing production errors.

- Automatic thickness adjustment: This feature allows the machine to automatically adjust roller settings based on the steel sheet thickness, optimizing production speed and material usage.

- Stacking and packaging systems: These integrated systems can automatically stack and package finished silo panels, streamlining the production workflow and reducing manual labor requirements.

The Future of Steel Silo Machines

The future of steel silo machines is brimming with potential. Here are some exciting trends to watch for:

- Increased automation: Expect even higher levels of automation, potentially leading to completely self-contained silo production lines.

- Focus on sustainability: Manufacturers might explore ways to reduce the environmental impact of steel silo machines, potentially through the use of recycled materials or energy-efficient processes.

- Integration with smart technologies: The future might see silo machines connected to the Internet of Things (IoT), allowing for remote monitoring and real-time adjustments for optimal silo production.

पूछे जाने वाले प्रश्न

Q: Can I operate a steel silo machine without prior experience?

A: While some basic models might be user-friendly, operating a steel silo machine typically requires a certain level of training. Understanding the machine’s functionalities, safety protocols, and proper maintenance procedures is crucial for efficient and safe operation. Many manufacturers offer training programs for their equipment.

Q: How long does it take to produce a steel silo using a silo machine?

A: Production time depends on the size and complexity of the silo, as well as the machine’s capabilities. However, a typical silo machine can produce panels for a small to medium-sized silo within a few hours.

Q: What maintenance does a steel silo machine require?

A: Regular maintenance is essential to ensure the smooth operation and longevity of your steel silo machine. This typically involves tasks like lubricating moving parts, inspecting rollers for wear and tear, and keeping the machine clean. Consulting the manufacturer’s recommended maintenance schedule is crucial for optimal performance.

Q: Are there safety risks associated with operating a steel silo machine?

A: As with any industrial machinery, steel silo machines come with inherent safety risks. These can include pinch points, shearing hazards, and potential for falling objects. Following proper safety protocols, including wearing appropriate personal protective equipment (PPE) and adhering to operational guidelines, is paramount to minimizing these risks.

Q: Where can I find more information about steel silo machines?

A: Several resources can provide valuable information about steel silo machines:

- Manufacturer websites: Most reputable steel silo machine manufacturers maintain detailed websites showcasing their product offerings, specifications, and often even educational resources about silo construction.

- Industry associations: Organizations like the American Feed Industry Association (AFIA) or the National Grain and Feed Association (NGFA) might offer resources related to silo storage and construction, potentially including information about silo machines.

- Online publications: Trade publications and websites catering to the agricultural, construction, or metalworking industries might publish articles or resources featuring steel silo machines.

निष्कर्ष

Steel silo machines are the backbone of the industrial storage landscape. These remarkable machines transform sheets of metal into the building blocks for colossal silos, safeguarding a wealth of materials across various industries. From the towering giants gracing agricultural fields to the discreet workhorses within industrial facilities, steel silo machines play a vital role in our world. By understanding their function, advantages, and considerations, you can make informed decisions when venturing into the world of silo construction. So, the next time you see a silo standing tall, remember the silent hero behind its creation – the steel silo machine.