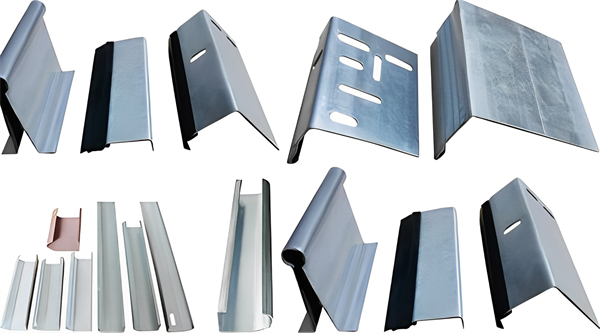

With steel roll forming machines, you can produce a variety of different products, from automotive parts to appliance casings. These machines use rotating dies to create shapes from sheet metal, and they’re very easy to use. This guide will teach you everything you need to know about steel roll forming machines, from the basics to more advanced techniques.

स्टील रोल बनाने की मशीन क्या है?

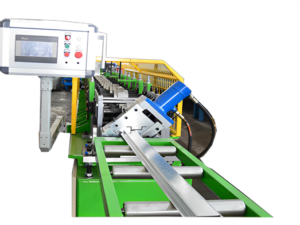

Steel roll forming machines are a type of automatic manufacturing machine that is used to create round steel objects from a flat sheet. The process begins by feeding the rolled steel sheet into the machine, where it is cut into desired shapes by the two rotating cutting blades. Once each shape has been cut, the blades move onto the next sheet, creating a continuous loop of steel rounds. The rounds are then moved to a cooling station where they are quickly cooled and hardened.

There are several types of steel roll forming machines on the market today. The most common is the hydraulic press machine, which uses hydraulic pressure to deform the metal. Other machines use mechanical force to deform the metal, including the die caster and straight milling machines.

How does a steel roll forming machine work?

A steel roll forming machine is similar to a pipe bending machine, in that it bends metal into desired shapes. However, the main difference between these machines is that steel roll forming machines can form much thicker pieces of metal than pipe bending machines. This is because a steel roll forming machine uses a series of cylindrical dies to shape the metal. The metal is fed into the die and then squeezed between the die and a stationary wall, forcing the metal into a predetermined shape.

One of the key benefits of using a steel रोल बनाना machine is that it can create very complex and intricate pieces of metal. This is because the die can be moved around the metal piece, which allows for more precise shaping. Additionally, steel roll forming machines are versatile tools, which means they can be used to create a variety of different objects. This includes items such as parts for cars, laptops, and even weapons.

-

दीवार कोण रोल बनाने की मशीन

दीवार कोण रोल बनाने की मशीन -

टी बार रोल बनाने की मशीन

टी बार रोल बनाने की मशीन -

सी रोल बनाने की मशीन

सी रोल बनाने की मशीन -

जेड शहतीर रोल बनाने की मशीन

जेड शहतीर रोल बनाने की मशीन -

एम शहतीर रोल बनाने की मशीन

एम शहतीर रोल बनाने की मशीन -

ओमेगा छत बैटन शीर्ष टोपी चैनल रोल बनाने की मशीन

ओमेगा छत बैटन शीर्ष टोपी चैनल रोल बनाने की मशीन -

मेटल कील ड्राईवॉल स्टड ट्रैक रोल बनाने की मशीन1 ग्राहक रेटिंग के आधार पर 5 में से ��ा मूल्यांकन किया गया

मेटल कील ड्राईवॉल स्टड ट्रैक रोल बनाने की मशीन1 ग्राहक रेटिंग के आधार पर 5 में से ��ा मूल्यांकन किया गया -

मचान तख्त रोल बनाने की मशीन

मचान तख्त रोल बनाने की मशीन -

धातु इस्पात संरचना डेक फर्श डेक रोल बनाने की मशीन

धातु इस्पात संरचना डेक फर्श डेक रोल बनाने की मशीन

Benefits of using a steel roll forming machine

If you’re in the market for a steel roll forming machine, there are many benefits to consider. These machines allow you to produce high-quality products quickly and easily, making them a popular choice for manufacturers and production lines. Here are some of the biggest benefits:

- Speed and Efficiency: Steel roll forming machines are incredibly fast and efficient, making it easy to produce high-quality products. They can also be used to create intricate shapes and designs, making them an ideal tool for manufacturers who need quick turnaround times.

- Precision and Accuracy: Steel roll forming machines are highly accurate, meaning that you can ensure that your products are exactly how you want them. This is especially important when producing unique or customized items, as mistakes made during manufacturing can be costly and time-consuming to remedy.

- Durability:Steel roll forming machines are built to last, making them a popular choice for manufacturing companies that require durable products. They can also be used to create components that require strong structural integrity, such as cars and aircrafts.

- Customizable Designs: With steel roll forming machines, you can create any kind of design that you desire – from simple shapes such as circles and rectangles, to more complicated designs such as tubes and wires. This makes them an ideal tool for creating custom products ornaments or accessories.

What to consider when purchasing a steel roll forming machine?

When purchasing a steel roll forming machine, there are a few things to consider. One of the most important factors is the type of material you will be working with. Steel is a very hard material and needs to be handled correctly if it is going to be used in a roll forming machine.

The other important factor to consider is the size of the machine. The bigger the machine, the more material you can process at one time. However, larger machines can also be more expensive. It is important to find a balance between size and price so that you can get the best machine for your needs.

Another factor to consider when purchasing a steel roll forming machine is how often it will need maintenance or repairs. Steel roll forming machines require regular maintenance in order to function properly. This includes cleaning the blades and gears, checking alignment, and inspecting for wear and tear. If you purchase a machine that doesn’t require regular maintenance, then you may have to spend more money down the road on repairs or replacements.

Overall, these are just some of the things that you should think about when purchasing a steel roll forming machine. Once you have chosen what type of material you will be working with and determined how large the machine will be, you can start shopping for the perfect model!