Когда вы ищете станок для вальцовки стальных шпилек, бывает трудно понять, с чего начать. На рынке представлено так много различных моделей, и у каждой из них есть свои преимущества и недостатки. Однако не волнуйтесь - в этой статье мы рассмотрим некоторые из лучших станков для вальцовки стальных шпилек, представленных на рынке, и поможем вам решить, какой из них подходит именно вам.

Что такое машина для формовки стальных стержней?

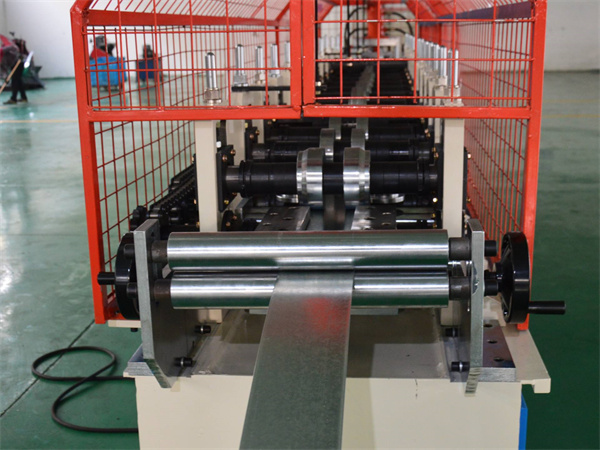

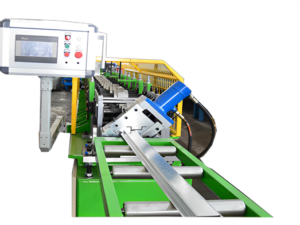

А профилегибочная машина для стальных шпилек это специализированное оборудование, которое используется для производства стальных шпилек. Эти шпильки используются в различных областях, таких как строительство зданий, промышленное оборудование и автомобили.

Основной принцип работы вальцовочного станка для производства стальных шпилек прост. Ряд валков устанавливается на раме, и металлические шпильки подаются на валки по одной. Затем валки деформируют металлическую шпильку в желаемую форму, которая может включать квадратные или круглые профили.

Одним из ключевых преимуществ использования оборудования для вальцовки стальных шпилек является то, что оно может создавать очень точные формы. Это происходит благодаря тому, что валки точно контролируются, обеспечивая последовательную деформацию металлических шпилек. Кроме того, этот тип станков очень быстрый и эффективный, что делает его идеальным для крупносерийного производства.

Типы машин для формовки стальных стержней

Существует несколько типов машин для штамповки шпилек, из которых можно выбрать идеальную для ваших конкретных нужд. Наиболее распространенным типом является пресс с открытым штампом, который использует пуансоны и штампы для придания стальным шпилькам нужной формы. Этот тип машины относительно прост в эксплуатации, но может потребовать больше времени и усилий, чем другие варианты.

Другим распространенным вариантом является пресс с закрытым штампом, который использует круглые пуансоны и штампы для создания однородных стальных шипов. Эта машина более сложна и трудна в использовании, чем пресс с открытыми штампами, но при этом обеспечивает большую точность и контроль. Наконец, существует ротационный пресс, который использует серию вращающихся штампов для создания нестандартных форм из стальных шпилек. Этот вариант является наиболее универсальным, так как может использоваться для производства изделий различных форм и размеров.

-

Профилегибочная машина для производства уголков стен

Профилегибочная машина для производства уголков стен -

Профилегибочная машина для Т-образных стержней

Профилегибочная машина для Т-образных стержней -

C Профилегибочная машина

C Профилегибочная машина -

Профилегибочная машина Z Purlin

Профилегибочная машина Z Purlin -

Профилегибочная машина M Purlin

Профилегибочная машина M Purlin -

Профилегибочная машина для кровельной обрешетки Omega Top Hat

Профилегибочная машина для кровельной обрешетки Omega Top Hat -

Профилегибочная машина для металлических килевых стоек для гипсокартонаРейтинг 5.00 из 5 на основе опроса 1 пользователя

Профилегибочная машина для металлических килевых стоек для гипсокартонаРейтинг 5.00 из 5 на основе опроса 1 пользователя -

Профилегибочная машина для строительных лесов

Профилегибочная машина для строительных лесов -

Профилегибочная машина для настила пола настила с металлической стальной конструкцией

Профилегибочная машина для настила пола настила с металлической стальной конструкцией

Как найти лучший станок для формовки стальных стержней?

Существует множество различных типов стальных шпилек профилирование машин на рынке, и бывает трудно определить, какая из них подходит для ваших нужд. Вот несколько советов, которые помогут вам найти лучший станок для вальцовки стальных шпилек для вашего бизнеса:

- Определите свои потребности

Прежде всего, необходимо решить, какой тип вальцовочных станков для стальных шпилек вам нужен. Существует два основных типа: ручные и автоматические. Ручные вальцовочные станки требуют, чтобы ими управлял человек, в то время как автоматические станки управляются машинами.

- Учитывайте размер и вместимость

Далее следует рассмотреть размер и производительность. Вам нужна машина, способная одновременно обрабатывать большое количество изделий, а также способная быстро производить высококачественные рулоны.

- Учитывайте стоимость и простоту использования

Наконец, обратите внимание на стоимость и простоту использования. Вы не хотите тратить слишком много денег на машину, которая сложна в эксплуатации или обслуживании, но вы также не хотите, чтобы она была слишком простой в использовании.

Где найти лучший?

Ищете станок для вальцовки стальных шпилек? Вы можете найти отличные предложения как в Интернете, так и в местном хозяйственном магазине. Вот несколько советов, которые помогут вам найти лучшее предложение:

- Проведите исследование. Сравните цены и характеристики различных машин, прежде чем совершить покупку.

- Поспрашивайте. Узнайте у друзей, родственников или коллег, не знают ли они о хороших предложениях на шипорезные вальцовочные станки.

- Зайдите в интернет. Многие продавцы предлагают скидки и бесплатную доставку при заказе на сумму свыше определенного количества долларов. Наберите в поисковике "станок для формирования стальных шипов", чтобы найти лучшие предложения в Интернете.

- Проверьте местные дилерские центры и магазины промышленных товаров. Многие дилерские центры предлагают подержанные машины, которые были отремонтированы или возвращены предыдущими владельцами. В магазинах промышленных товаров часто продаются как новые, так и бывшие в употреблении машины, а также могут быть специальные предложения или скидки на конкретные модели шипорезных вальцовочных станков.

Вывод

В этой статье мы рассмотрели различные типы станков для вальцовки стальных шипов и их преимущества. Мы также предоставили руководство для покупателей, чтобы помочь вам принять обоснованное решение о том, какой станок лучше всего подходит для ваших нужд. Если вы хотите начать бизнес по прокатке стальных шпилек или просто модернизировать существующий процесс, выбор правильного станка очень важен. Итак, читайте дальше и узнайте больше о каждом типе станков для прокатки стальных шпилек!