Giriş

Aşık rulo şekillendirme makineleri aşıkların oluşturulmasındaki verimlilikleri ve hassasiyetleri nedeniyle inşaat sektöründe büyük bir popülerlik kazanmıştır. Aşıklar, bir binanın çatısına veya duvarlarına yapısal destek sağladıkları için çatı kaplama ve inşaat projelerinin önemli bir bileşenidir. Bu makalede, aşık rulo şekillendirme makinelerine, türlerine, özelliklerine, faydalarına ve bir tane satın alırken göz önünde bulundurulması gereken faktörlere daha yakından bakacağız.

1. Aşık Rulo Şekillendirme Makineleri Çeşitleri

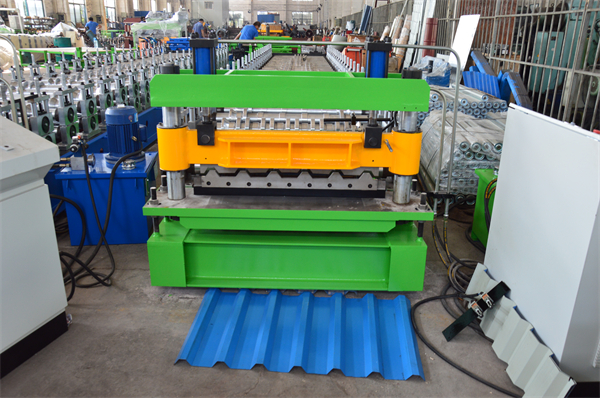

C Aşık Rulo Şekillendirme Makinesi

Bir C aşık rulo şekillendirme makinesi, inşaat projelerinde yaygın olarak kullanılan C-şekilli aşıklar oluşturmak için tasarlanmıştır. Bu makineler tipik olarak tam otomatiktir ve çeşitli kalınlık ve uzunluklarda aşıklar üretebilir.

Z Aşık Rulo Şekillendirme Makinesi

Bir Z aşık rulo şekillendirme makinesi, inşaat projelerinde çatı ve duvarlar için yapısal destek olarak kullanılan Z şekilli aşıklar oluşturmak için tasarlanmıştır. Bu makineler aynı zamanda tam otomatiktir ve farklı kalınlık ve uzunluklarda aşıklar üretebilir.

U Aşık Rulo Şekillendirme Makinesi

Bir U aşık rulo şekillendirme makinesi, inşaat projelerinde çatılar, duvarlar ve tavanlar için yapısal destek olarak kullanılan U şeklinde aşıklar oluşturmak üzere tasarlanmıştır. Bu makineler aynı zamanda tam otomatiktir ve çeşitli kalınlık ve uzunluklarda aşıklar üretebilir.

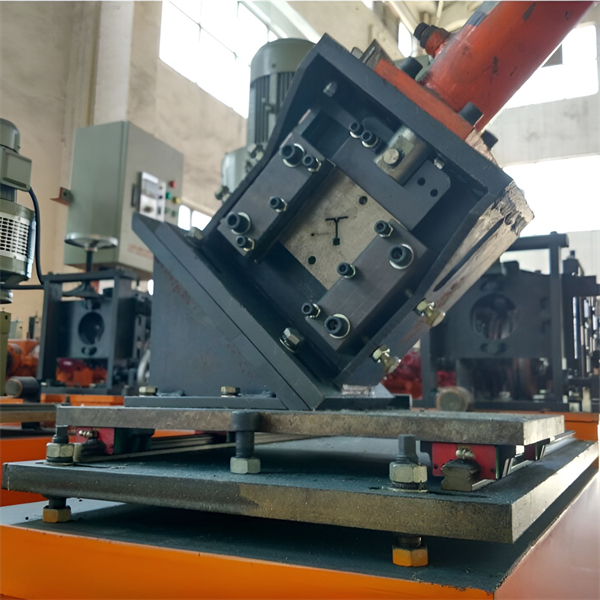

Özel Aşık Rulo Şekillendirme Makinesi

Özel bir aşık rulo şekillendirme makinesi, müşterinin gereksinimlerine göre belirli boyutlarda ve şekillerde aşıklar oluşturmak için tasarlanmıştır. Bu makineler çok yönlüdür ve C, Z ve U aşıkları dahil olmak üzere çeşitli şekil ve boyutlarda aşıklar oluşturmak için kullanılabilir.

2. Satılık Aşık Rulo Şekillendirme Makinesi

Aşık Rulo Şekillendirme Makinesi Satın Almanın Faydaları

Bir aşık rulo şekillendirme makinesine yatırım yapmak, inşaat işletmelerine çok sayıda fayda sağlayabilir. Bu avantajlardan bazıları şunlardır:

- Maliyet Tasarrufu: Bir aşık rulo şekillendirme makinesi satın almak, aşık üretimini dışarıdan temin etme ihtiyacını ortadan kaldırdığı için inşaat işletmelerinin uzun vadede tasarruf etmesine yardımcı olabilir.

- Artan Verimlilik: Aşık rulo şekillendirme makineleri, manuel üretime göre çok daha hızlı bir şekilde aşık üretebilir ve böylece verimliliği artırır.

- Tutarlı Kalite: Aşık rulo şekillendirme makineleri, tutarlı kalite ve hassasiyette aşıklar oluşturarak her bir aşığın gerekli özellikleri karşılamasını sağlar.

- Özelleştirme: Özel aşık rulo şekillendirme makineleri, müşterinin gereksinimlerine göre belirli boyutlarda ve şekillerde aşıklar oluşturabilir ve inşaat işletmelerinin daha geniş bir proje yelpazesine hitap etmesine olanak tanır.

Aşık Rulo Şekillendirme Makinesi Satın Alırken Dikkat Edilmesi Gereken Faktörler

Bir aşık rulo şekillendirme makinesi satın alırken, makinenin işletmenin gereksinimlerini karşıladığından emin olmak için çeşitli faktörlerin dikkate alınması gerekir. Dikkate alınması gereken faktörlerden bazıları şunlardır:

- Malzeme Kalınlığı: Aşıklar için kullanılacak malzemelerin kalınlığı, makine seçimi yapılırken göz önünde bulundurulmalıdır.

- Üretim Kapasitesi: İşletmenin talebini karşılayabilmesini sağlamak için makinenin üretim kapasitesinin değerlendirilmesi gerekir.

- Özelleştirme: İşletme özelleştirilmiş aşıklar gerektiriyorsa, özel bir aşık rulo şekillendirme makinesinin düşünülmesi gerekir.

- Fiyat: Makinenin fiyatı, işletmenin bütçesine uygun olduğundan emin olmak için dikkate alınmalıdır.

3. Aşık Rulo Şekillendirme Makinesi Üreticisi

Doğru Aşık Rulo Şekillendirme Makinesi Üreticisini Seçme

Doğru aşık rulo şekillendirme makinesi üreticisini seçmek, makinenin işletmenin gereksinimlerini ve beklentilerini karşıladığından emin olmak için çok önemlidir. Bir üretici seçerken göz önünde bulundurulması gereken faktörlerden bazıları şunlardır:

- Deneyim: Üreticinin sektördeki deneyimi ve piyasadaki itibarı, uzmanlıkları ve güvenilirlikleri hakkında fikir verebilir.

- Kalite: Şirket tarafından üretilen makinelerin kalitesi, önceki projeleri ve müşteri yorumları incelenerek değerlendirilmelidir.

- Özelleştirme: İşletme özel bir aşık rulo şekillendirme makinesi gerektiriyorsa, üreticinin özelleştirme hizmetleri sunma yeteneği değerlendirilmelidir.

- Teknik Destek: Üreticinin teknik destek ve satış sonrası hizmetleri, herhangi bir sorun veya bakım ihtiyacının derhal ele alınabilmesini sağlamak için değerlendirilmelidir.

4. Satılık Kullanılmış Aşık Rulo Şekillendirme Makinesi

Kullanılmış Aşık Rulo Şekillendirme Makinesi Satın Almanın Avantaj ve Dezavantajları

Kullanılmış bir aşık rulo şekillendirme makinesi satın almak işletmeler için uygun maliyetli bir seçenek olabilir. Ancak, kullanılmış bir makine satın almanın hem avantajlarını hem de dezavantajlarını göz önünde bulundurmak önemlidir.

Avantajlar

- Maliyet Tasarrufu: Kullanılmış aşık rulo şekillendirme makineleri genellikle yeni makinelerden daha ucuzdur ve işletmeye maliyet tasarrufu sağlar.

- Kullanılabilirlik: Kullanılmış makineler kolayca temin edilebilir ve üretim sürecini beklemeden satın alınabilir.

Dezavantajlar

- Durum: Kullanılmış makinenin durumu bilinmeyebilir ve onarım veya bakım gerektirebilir, bu da toplam maliyeti artırabilir.

- Teknoloji: Kullanılmış makineler en son teknolojiye sahip olmayabilir, bu da verimliliği ve üretkenliği etkileyebilir.

Kullanılmış Aşık Rulo Şekillendirme Makinesi Satın Alırken Dikkat Edilmesi Gereken Faktörler

Kullanılmış bir aşık rulo şekillendirme makinesi satın alırken, makinenin iyi durumda olduğundan ve işletmenin gereksinimlerini karşılayabildiğinden emin olmak için belirli faktörlerin dikkate alınması gerekir. Dikkate alınması gereken faktörlerden bazıları şunlardır:

- Durum: Bileşenlerin kalitesi ve aşınma ve yıpranma seviyesi de dahil olmak üzere makinenin genel durumu değerlendirilmelidir.

- Yaş: Makinenin yaşı, kullanılan teknoloji ve bakım ihtiyaçları hakkında bir fikir verebilir.

- Bakım Kayıtları: Makinenin bakım kayıtları, makinenin bakımının düzgün bir şekilde yapıldığından emin olmak için gözden geçirilmelidir.

- Uyumluluk: Makinenin işletmenin mevcut ekipman ve süreçleriyle uyumluluğu değerlendirilmelidir.

OEM Aşık Rulo Şekillendirme Makinesi

Bir OEM aşık rulo şekillendirme makinesi, orijinal ekipman üreticisi (OEM) tarafından tasarlanır ve üretilir. OEM makineler genellikle daha yüksek kalitededir ve güvenilir teknik destek ve satış sonrası hizmetlerle birlikte gelir.

Sonuç

Bir aşık rulo şekillendirme makinesine yatırım yapmak, inşaat işletmelerine maliyet tasarrufu, artan verimlilik, tutarlı kalite ve özelleştirme gibi önemli faydalar sağlayabilir. Bir aşık rulo şekillendirme makinesi satın alırken, işletmelerin malzeme kalınlığı, üretim kapasitesi, özelleştirme ve fiyat gibi faktörleri göz önünde bulundurması gerekir. Doğru üreticiyi seçmek ve kullanılmış bir makine satın almanın avantaj ve dezavantajlarını göz önünde bulundurmak da çok önemlidir. Bir OEM aşık rulo şekillendirme makinesi en yüksek kaliteyi ve güvenilirliği sağlayabilir, bu da onu inşaat sektöründeki işletmeler için değerli bir yatırım haline getirir.

SSS

- Aşık rulo şekillendirme makinesi nedir?

- Piyasada ne tür aşık rulo şekillendirme makineleri mevcuttur?

- Aşık rulo şekillendirme makinesi satın almanın faydaları nelerdir?

- Doğru aşık rulo şekillendirme makinesi üreticisini nasıl seçerim?

- Yeni veya kullanılmış bir aşık rulo şekillendirme makinesi satın almak daha mı iyidir?