Roll forming machines are versatile and efficient manufacturing tools used in various industries. These machines play a crucial role in shaping metal sheets into desired profiles with high precision and repeatability. By gradually bending the metal through a series of roll stations, roll forming machines can produce continuous profiles of uniform cross-sections.

1. Introduction

Roll forming machines have revolutionized the metalworking industry, offering a cost-effective solution for mass production of metal components. Whether it’s for construction, automotive, or other industries, these machines have become indispensable in manufacturing processes. In this article, we will explore the different types of roll forming machines and their applications, focusing on double layer roll forming machines, fascia roll forming machines, cladding roll forming machines, flashing roll forming machines, and floor deck roll forming machines.

2. Overview of Roll Forming Machines

Before diving into specific types, let’s understand the basic working principle and components of roll forming machines. A roll forming machine consists of a series of rolls, also known as roll stations, mounted on shafts. These rolls progressively shape the metal strip as it passes through the machine. The metal strip is fed into the machine and guided through different stages, where each roll station performs a specific bending or forming operation. The final product is a continuous metal profile with a consistent cross-section.

Working Principle of Roll Forming Machines

Roll forming machines use a continuous bending process to shape metal sheets. As the metal strip passes through the machine, it is gradually bent and formed by the successive roll stations. Each roll station is equipped with a set of rolls that incrementally deform the metal strip, gradually transforming it into the desired profile. The number and arrangement of roll stations vary depending on the complexity of the profile.

Components of a Roll

Forming Machine A roll forming machine comprises several essential components that work together to ensure smooth and efficient operation:

- Uncoiler: This component holds the metal coil and feeds the strip into the roll forming machine. It unwinds the coil in a controlled manner, providing a continuous supply of material.

- Feeding System: The feeding system transports the metal strip from the uncoiler to the first roll station. It ensures proper alignment and smooth movement of the strip during the forming process.

- Roll Stations: Roll stations consist of a series of rolls mounted on shafts. Each roll station performs a specific bending or forming operation on the metal strip as it passes through. The rolls are designed to gradually shape the strip into the desired profile.

- Cutting Mechanism: In some roll forming machines, a cutting mechanism is incorporated to separate the finished profiles from the continuous strip. It can be a flying cutoff, hydraulic shear, or other cutting methods depending on the requirements.

- Control System: The control system governs the overall operation of the roll forming machine. It regulates the speed, feeding, and cutting processes, ensuring precise and consistent forming of the profiles.

3. Double Layer Roll Forming Machine

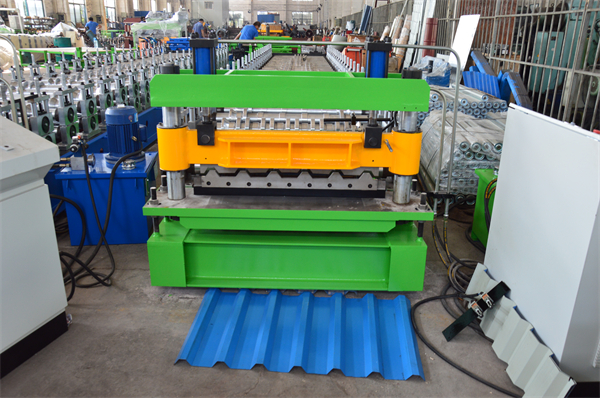

Introduction to Double Layer Roll Forming Machine

A double layer roll forming machine is a specialized type of roll forming equipment that allows the simultaneous production of two different profiles. It consists of two independent roll forming lines stacked vertically, with each line dedicated to forming a specific profile. This machine offers increased productivity and versatility, making it ideal for industries requiring multiple profiles.

Working Process and Features

The working process of a double layer roll forming machine involves feeding two separate metal strips into the respective roll forming lines. Each line operates independently, with the strips passing through their dedicated roll stations. The final output is two continuous profiles of different shapes and sizes.

One notable feature of a double layer roll forming machine is its quick changeover capability. It enables rapid transition between different profile setups, minimizing downtime and maximizing productivity. The machine is equipped with adjustable roll stands and tooling, allowing for easy customization and adjustment according to specific profile requirements.

Applications and Benefits

Double layer roll forming machines find extensive use in industries such as roofing, construction, and automotive, where multiple profiles are required for various applications. Some common applications include roof panels, wall cladding, garage doors, partition systems, and more.

The key benefits of using a double layer roll forming machine include:

- Increased Efficiency: With the ability to produce two different profiles simultaneously, the machine offers improved productivity and reduced production time.

- Cost Savings: By eliminating the need for separate machines or setups for each profile, manufacturers can achieve cost savings in terms of equipment, space, and labor.

- Versatility: The machine allows for flexibility in producing different profiles, enabling manufacturers to meet diverse customer demands and expand their product offerings.

- Consistency and Accuracy: Double layer roll forming machines ensure precise and consistent forming of profiles, resulting in high-quality end products.

Key Considerations when Choosing a Double Layer Roll Forming Machine

When selecting a double layer roll forming machine, several factors need to be considered:

- Profile Complexity: Evaluate the complexity of the profiles you intend to produce and ensure that the machine can handle the required design and specifications.

- Material Compatibility: Consider the types of materials (e.g., steel, aluminum) the machine can process, as well as their thickness and strength requirements.

- Changeover Time: Look for machines that offer quick and easy changeover between different profiles, reducing downtime and optimizing production efficiency.

- Customization Options: Check if the machine can be customized to accommodate specific profile requirements or if it offers a range of standard profiles that meet your needs.

- Quality and Reliability: Research the reputation and track record of the manufacturer to ensure the machine’s quality, durability, and long-term reliability.

- After-Sales Support: Consider the availability of technical support, maintenance services, and spare parts to ensure smooth operation and minimize downtime.

4. Fascia Roll Forming Machine

Overview of Fascia Roll Forming Machine

A fascia roll forming machine is specifically designed to produce fascia profiles, which are commonly used in roofing and architectural applications. Fascia refers to the vertical facing or finishing edge of a roof or wall, providing an aesthetically pleasing appearance while protecting the underlying structure. The fascia roll forming machine enables efficient and precise production of fascia profiles with consistent quality.

Key Features and Advantages

Fascia roll forming machines come with unique features tailored for fascia profile production:

- Multiple Forming Stations: These machines have a sufficient number of forming stations to achieve the desired profile shape and dimensions. The number of stations can be adjusted based on the complexity of the fascia design.

- Precision Roll Tooling: The roll tooling is engineered to ensure accurate and consistent forming of the fascia profile, maintaining uniformity throughout the production process.

- Customizable Design: Fascia roll forming machines often offer customization options to meet specific customer requirements. This includes the ability to adjust the dimensions, angles, and details of the fascia profiles.

- Efficient Production Speed: The machines are designed for high-speed production, optimizing productivity without compromising quality.

Typical Applications and Industries

Fascia profiles produced by roll forming machines are widely used in various industries and applications, including:

- Roofing: Fascia profiles provide an attractive and functional finishing touch to roofing systems, enhancing their overall appearance and protecting the edges.

- Architectural: Fascia profiles are used in architectural applications to create a clean and seamless transition between different building elements, such as walls, roofs, and eaves.

- Commercial Buildings: Commercial structures, such as offices, retail spaces, and industrial facilities, often utilize fascia profiles for both functional and aesthetic purposes.

- Residential Construction: Fascia profiles are common in residential construction for their ability to enhance the visual appeal and durability of roofs and exteriors.

Factors to Consider when Selecting a Fascia Roll Forming Machine

When choosing a fascia roll forming machine, consider the following factors:

- Profile Design and Flexibility: Ensure that the machine can produce the specific fascia profile designs you require. It should offer flexibility in terms of dimensions, angles, and customization options.

- Material Compatibility: Verify that the machine can handle the materials commonly used for fascia profiles, such as steel or aluminum, with the required thickness and strength.

- Production Speed: Evaluate the machine’s production speed capabilities to match your desired output and meet production deadlines.

- Quality and Accuracy: Look for a machine that provides precise and consistent forming of fascia profiles, ensuring high-quality end products.

- Ease of Use and Maintenance: Consider the ease of machine operation, setup, and maintenance requirements to optimize production efficiency and minimize downtime.

5. Cladding Roll Forming Machine

Introduction to Cladding Roll Forming Machine

A cladding roll forming machine is designed to produce cladding panels used for external wall coverings in residential, commercial, and industrial buildings. Cladding panels provide insulation, weather protection, and aesthetic appeal to the building envelope. The cladding roll forming machine enables efficient production of these panels with various profiles and finishes.

Working Process and Benefits

The cladding roll forming machine operates by continuously feeding the metal strip through multiple roll stations. Each roll station performs specific bending and forming operations, gradually shaping the strip into the desired cladding profile. The machine allows for customization in terms of panel width, length, thickness, and surface finish.

The benefits of using a cladding roll forming machine include:

- Versatility: The machine can produce a wide range of cladding panel profiles, including ribbed, corrugated, standing seam, and more. This versatility allows for diverse design options to suit different architectural styles.

- Efficiency: Cladding roll forming machines enable high-speed production, ensuring efficient manufacturing processes and meeting project deadlines.

- Cost-effectiveness: Roll forming offers a cost-effective solution for cladding panel production, minimizing material waste and reducing labor costs compared to other fabrication methods.

- Consistent Quality: The machine ensures consistent quality and dimensional accuracy of the cladding panels, meeting industry standards and specifications.

Common Applications and Materials Used

Cladding panels produced by roll forming machines find applications in various industries and building types:

- Commercial and Residential Construction: Cladding panels are extensively used in the construction of commercial buildings, residential complexes, and housing projects. They provide weather protection, insulation, and enhance the visual appeal of the building exteriors.

- Industrial Facilities: Industrial buildings, warehouses, and manufacturing facilities often utilize cladding panels for their durability, low maintenance requirements, and resistance to harsh environmental conditions.

- Architectural Projects: Cladding panels are favored in architectural projects to create unique façade designs, adding depth, texture, and visual interest to the building envelope.

The materials commonly used for cladding panels include steel, aluminum, stainless steel, and composite materials. The choice of material depends on factors such as desired aesthetics, durability, and specific project requirements.

Factors to Consider for Cladding Roll Forming Machine Selection

When selecting a cladding roll forming machine, consider the following factors:

- Profile Design and Customization: Assess the machine’s capability to produce the desired cladding panel profiles, including the ability to customize dimensions, rib patterns, and surface finishes.

- Material Compatibility: Verify that the machine can handle the materials you plan to use for cladding panels, considering their thickness, strength, and surface coating requirements.

- Production Speed and Capacity: Evaluate the machine’s production speed and capacity to meet your project deadlines and output requirements.

- Quality Control and Accuracy: Look for a machine that ensures precise forming and consistent quality of cladding panels, minimizing wastage and rework.

- Ease of Operation and Maintenance: Consider the machine’s user-friendly interface, ease of setup, and maintenance requirements to optimize productivity and minimize downtime.

6. Flashing Roll Forming Machine

Overview of Flashing Roll Forming Machine

A flashing roll forming machine is specifically designed to produce metal flashings used in construction and roofing applications. Flashings are thin strips of metal that are used to waterproof and protect joints, seams, and transitions in roofs, walls, and other building elements. The flashing roll forming machine enables efficient production of these custom-shaped metal flashings.

Working Mechanism and Advantages

The flashing roll forming machine operates by gradually bending and forming the metal strip into the desired flashing profile. The machine is equipped with multiple roll stations, each performing specific bending and shaping operations. The advantages of using a flashing roll forming machine include:

- Customized Flashing Profiles: The machine allows for the production of flashings in various shapes, sizes, and configurations to suit specific project requirements.

- Consistent Quality: Flashing roll forming machines ensure consistent quality and dimensional accuracy of flashings, meeting industry standards and specifications.

- Cost and Time Efficiency: Roll forming flashings offers cost and time efficiencies compared to traditional fabrication methods. The machine can produce flashings in a continuous process, minimizing material waste and reducing labor costs.

- Wide Range of Materials: Flashing roll forming machines can work with different materials, such as aluminum, steel, copper, or galvanized metal, allowing flexibility in material selection based on project needs.

Uses of Flashing Roll Forming Machines

Flashings produced by roll forming machines have a wide range of applications in the construction industry:

- Roofing: Flashings are commonly used in roofing systems to provide watertight seals at roof transitions, valleys, chimneys, skylights, and vents.

- Wall Systems: Flashings are utilized in wall systems to protect and seal joints between different wall materials, such as siding, cladding, or masonry.

- Window and Door Installations: Flashings are crucial in window and door installations to prevent water infiltration and ensure proper sealing around the openings.

- Waterproofing: Flashings play a vital role in waterproofing applications, ensuring the integrity and durability of building envelopes.

Important Factors to Consider when Buying a Flashing Roll Forming Machine

When selecting a flashing roll forming machine, consider the following factors:

- Flashing Profile Flexibility: Evaluate the machine’s ability to produce various flashing profiles, including custom shapes and dimensions required for specific project needs.

- Material Compatibility: Verify that the machine can work with the materials commonly used for flashings, such as aluminum, steel, or copper, with the required thickness and strength.

- Production Speed and Efficiency: Assess the machine’s production speed and efficiency to meet project timelines and production demands.

- Tooling Customization: Check if the machine allows for easy adjustment and customization of roll tooling to accommodate different flashing profile designs.

- Quality Control and Precision: Look for a machine that ensures high-quality forming and consistent accuracy in producing flashings, minimizing errors and rework.

- Ease of Operation and Maintenance: Consider the machine’s user-friendly interface, ease of setup, and maintenance requirements to ensure smooth operation and minimize downtime.

7. Floor Deck Roll Forming Machine

Introduction to Floor Deck Roll Forming Machine

A floor deck roll forming machine is designed to produce floor decking panels used in construction, particularly in composite floor systems. Floor decking panels are used as structural components to provide support, stability, and fire resistance in buildings. The floor deck roll forming machine enables efficient production of these panels with precise dimensions and high-quality finishes.

Working Principle and Features

The floor deck roll forming machine operates by continuously feeding the metal strip through a series of roll stations. Each station performs specific bending and shaping operations, gradually forming the metal strip into the desired floor deck profile. The key features of a floor deck roll forming machine include:

- Multiple Roll Stations: The machine is equipped with multiple roll stations to achieve the required profile shape and dimensions. The number of stations can vary based on the complexity and design of the floor deck profile.

- Efficient Material Utilization: Floor deck roll forming machines optimize material usage, minimizing waste and reducing costs in the production process.

- Speed and Productivity: These machines are designed for high-speed production, ensuring efficient manufacturing processes and meeting project deadlines.

- Quality Control and Precision: Floor deck roll forming machines ensure consistent quality and dimensional accuracy of the floor decking panels, meeting industry standards and specifications.

Applications and Benefits

Floor deck profiles produced by roll forming machines find extensive use in the construction industry, particularly in composite floor systems. Some benefits of using floor deck roll forming machines include:

- Structural Strength: Floor deck panels provide structural stability and support to buildings, contributing to the overall strength and load-bearing capacity of the structure.

- Fire Resistance: Floor deck panels are often designed to meet fire resistance requirements, enhancing the safety and compliance of the building.

- Ease of Installation: The design of floor deck profiles allows for easy and efficient installation, reducing construction time and labor costs.

- Versatility: Floor deck profiles can be customized to accommodate different span lengths, load requirements, and architectural specifications, providing versatility in design and application.

- Integration with Other Systems: Floor deck panels can seamlessly integrate with other building systems, such as concrete slabs, insulation, and mechanical and electrical services.

Key Factors to Consider when Selecting a Floor Deck Roll Forming Machine

When choosing a floor deck roll forming machine, consider the following factors:

- Profile Design and Customization: Evaluate the machine’s capability to produce the specific floor deck profiles required for your project, including span lengths, rib patterns, and other design specifications.

- Material Compatibility: Verify that the machine can work with the materials commonly used for floor deck panels, such as steel or galvanized steel, with the required thickness and strength.

- Production Speed and Capacity: Assess the machine’s production speed and capacity to meet your project timelines and output requirements.

- Quality Control and Precision: Look for a machine that ensures high-quality forming and dimensional accuracy of the floor deck panels, minimizing errors and rework.

- Ease of Operation and Maintenance: Consider the machine’s user-friendly interface, ease of setup, and maintenance requirements to optimize productivity and minimize downtime.

8. Conclusion

Roll forming machines play a vital role in the manufacturing of metal profiles used in various industries. In this article, we explored different types of roll forming machines, including double layer roll forming machines, fascia roll forming machines, cladding roll forming machines, flashing roll forming machines, and floor deck roll forming machines. Each type serves specific purposes and offers unique advantages in terms of efficiency, customization, and quality control.

By understanding the working principles, features, applications, and considerations of these machines, you can make informed decisions when selecting a roll forming machine that aligns with your production requirements. Whether you need to produce multiple profiles simultaneously, create precise fascia or cladding panels, manufacture custom flashings, or produce structural floor decking, there is a roll forming machine available to meet your needs.

Investing in a high-quality roll forming machine can significantly enhance your manufacturing capabilities, streamline production processes, and contribute to the success of your business.

FAQs

1.What is the difference between single layer and double layer roll forming machines?

2.How long does it take to set up a roll forming machine for a specific profile?

3.Are roll forming machines suitable for small-scale production?

4.Can roll forming machines be customized for specific shapes and sizes?

5.What maintenance is required for roll forming machines?