China telah terkenal dengan keterampilan manufaktur dan produk berkualitas. Gulungan Cina, yang merupakan lembaran logam tipis yang ditekuk menjadi bentuk melingkar di tengah dan digulung ke luar untuk membentuk tabung, adalah salah satu contohnya. Mesin pembuat gulungan atap logam baru ini adalah alat yang memudahkan pembengkokan lembaran logam tipis ini. Mesin ini tidak memerlukan alat yang dioperasikan dengan tangan atau mesin lain, cukup dengan satu operator. Selain itu, mesin ini dapat dijalankan tanpa pengawasan.

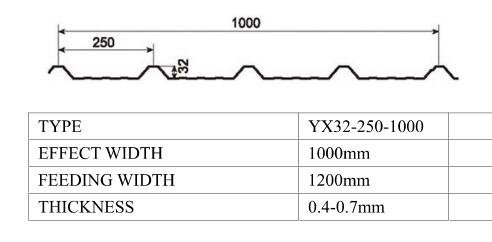

Gambar Profil panel atap mesin roll forming China

Proses teknis mesin roll forming panel atap China

Decoiler→ feeding dengan guide→roll forming→servo following cutting→conveyor belt→Stackers

Parameter teknis panel atap mesin roll forming China

- Kecepatan Bergulir: sekitar 30-40m/mnt

- Bahan yang akan diproses: Baja galvanis, Aluzinc, PPGI dari 0,3 mm hingga 0,8 mm

- Panjang maksimum lembaran yang akan dibongkar: 6 m

- Sistem Kontrol: PLC dengan layar sentuh

- Stasiun Roller: sekitar 20 stasiun

- Bahan Rol : Baja tempa 45#, dilapisi dengan krom

- Bahan Poros dan DIA: ¢76mm, bahannya adalah baja tempa 45#, Chrome dengan pendinginan

- Tenaga Motor: motor utama 22kw

- Tenaga hidrolik: 7.5kw

- Pemasok daya: 380V, 50HZ, 3 fase

- Cara Berkendara: Gearbox

- Ukuran mesin pembentuk: Sekitar 11.500 * 1700 * 1200mm

- Berat mesin: sekitar 10 ton

Mesin Daftar mesin roll forming panel atap

|

Daftar mesin

|

10 ton de-coiler dengan perangkat lengan | 1 set |

| Memberi makan dengan pemandu | 1 set | |

| Mesin pembentuk gulungan utama | 1 set | |

| Servo mengikuti pemotongan | 1 set | |

| Kotak kontrol | 1 unit | |

| Stasiun hidrolik | 1 unit | |

| ban berjalan 3 meter | 1 set | |

| Penumpuk otomatis 6m | 1 set | |

| Penutup pengaman | 1 set | |

| Suku cadang | 1 paket |

Data Teknis mesin roll forming panel atap:

10 ton de-coiler hidrolik dengan mobil koil

- Diameter bagian dalam koil: ¢508-610mm

- Max out diameter koil: ¢1250mm

- Lebar Kumparan Maks: 1250mm

Mesin pembentuk gulungan utama

Servo mengikuti perangkat Pemotongan

- Gerakan pemotongan: Servo mengikuti pemotongan

- Bahan pisau: CR12mov dengan perlakuan panas

- Pengukuran panjang & kuantitas secara otomatis;

- Ketebalan pemotongan: 0,2- 0,6mm

- Daya Stasiun Hidrolik: .5 KW

apa itu mesin roll forming atap logam?

Mesin roll forming atap logam adalah peralatan khusus yang digunakan dalam proses pembuatan atap logam. Ini dirancang untuk secara efisien dan akurat membentuk lembaran logam datar menjadi profil atap tertentu melalui proses pembentukan gulungan yang berkelanjutan.

Mesin ini biasanya terdiri dari serangkaian rol dan set perkakas yang secara bertahap membengkokkan dan membentuk lembaran logam ke profil yang diinginkan. Lembaran logam dimasukkan ke dalam mesin, dan ketika melewati rol, lembaran logam tersebut mengalami serangkaian operasi pembentukan, termasuk pembengkokan, pelipatan, dan pemotongan. Rol dan set perkakas dirancang dengan hati-hati untuk mencapai dimensi dan bentuk yang tepat untuk panel atap logam akhir.

Mesin roll forming atap logam tersedia dalam berbagai konfigurasi untuk mengakomodasi berbagai profil atap, bahan, dan kapasitas produksi. Mesin-mesin ini dapat menangani berbagai jenis lembaran logam, seperti baja, aluminium, atau tembaga, dengan ketebalan yang berbeda-beda. Mesin-mesin ini juga dapat menyertakan fitur tambahan seperti sistem pengumpanan otomatis, mekanisme pemotongan, dan sistem kontrol untuk produksi yang efisien dan otomatis.

Penggunaan mesin roll forming atap metal menawarkan beberapa keuntungan, termasuk kecepatan produksi yang tinggi, kualitas yang konsisten, dimensi yang presisi, dan pengurangan biaya tenaga kerja. Hal ini memungkinkan produksi massal panel atap metal dengan profil yang seragam dan memastikan pemasangan yang lebih cepat di lokasi konstruksi. Mesin ini banyak digunakan dalam industri atap untuk aplikasi perumahan, komersial, dan industri.

Manfaat mesin pembuat gulungan atap Cina

- Efektivitas biaya: Cina dikenal dengan harga yang kompetitif di bidang manufaktur. Mesin pembuat gulungan atap Cina seringkali lebih terjangkau dibandingkan dengan mesin dari negara lain. Keunggulan biaya ini memungkinkan bisnis untuk berinvestasi dalam peralatan berkualitas tinggi sambil meminimalkan pengeluaran mereka.

- Berbagai macam pilihan: Cina memiliki industri manufaktur yang luas dan beragam, menawarkan berbagai macam mesin pembuat gulungan atap. Anda dapat menemukan mesin dengan spesifikasi, kapasitas, dan fitur yang berbeda untuk memenuhi kebutuhan spesifik Anda. Apakah Anda memerlukan mesin untuk operasi skala kecil atau produksi industri skala besar, China dapat memberikan opsi yang sesuai.

- Teknologi canggih: Cina telah membuat langkah signifikan dalam mengadopsi dan berinovasi dalam teknologi manufaktur. Mesin pembuat gulungan atap Cina sering kali menggabungkan otomatisasi canggih, teknik presisi, dan sistem kontrol yang efisien. Kemajuan teknologi ini meningkatkan produktivitas, akurasi, dan kinerja secara keseluruhan, yang mengarah pada efisiensi yang lebih tinggi dan kualitas produk yang lebih baik.

- Kemampuan kustomisasi: Pabrikan Cina memahami pentingnya memenuhi kebutuhan pelanggan yang spesifik. Mereka menawarkan opsi penyesuaian untuk mesin pembuat gulungan atap, memungkinkan Anda menyesuaikan mesin sesuai dengan kebutuhan unik Anda. Baik itu menyesuaikan dimensi, profil, atau bahan, pabrikan Cina sering kali dapat mengakomodasi permintaan penyesuaian.

- Konstruksi berkualitas: Produsen Cina memprioritaskan kualitas dan daya tahan produk mereka. Mereka menggunakan bahan berkualitas tinggi, mempekerjakan teknisi yang terampil, dan mematuhi langkah-langkah kontrol kualitas yang ketat selama proses pembuatan. Hasilnya, mesin pembuat gulungan atap China dibuat untuk menahan penggunaan berat, memberikan kinerja yang konsisten, dan memiliki masa pakai yang lebih lama.

- Dukungan purna jual: Banyak pabrikan Tiongkok memberikan dukungan purna jual yang komprehensif, termasuk bantuan teknis, pelatihan, dan ketersediaan suku cadang. Hal ini memastikan bahwa pelanggan dapat menerima layanan dukungan dan pemeliharaan tepat waktu saat dibutuhkan, meminimalkan waktu henti dan memaksimalkan efisiensi alat berat.

- Kehadiran dan reputasi global: Pabrikan Cina telah membangun kehadiran yang kuat di pasar global untuk mesin pembuat gulungan atap. Mereka telah mendapatkan reputasi dalam memproduksi peralatan yang andal dan memberikan layanan berkualitas. Jaringan distribusi mereka yang luas dan kemitraan global memudahkan untuk mengakses produk dan layanan mereka di seluruh dunia.

Di mana saya dapat membeli mesin pembuat gulungan panel r Cina?

Jika Anda mencari mesin roll forming panel r China, taruhan terbaik Anda adalah memeriksa pengecer online atau toko fisik yang menjual peralatan mesin, seperti Susman mesin pembentuk gulungan. Selain itu, banyak toko perlengkapan industri memajang mesin yang mungkin dapat mereka sewa atau jual.

Perlu diingat bahwa harga mesin roll forming panel China r dapat sangat bervariasi tergantung pada model dan merek. Beberapa model lebih murah daripada yang lain, tetapi semuanya menawarkan Hasil berkualitas tinggi. Cara terbaik untuk menentukan apakah mesin pembuat gulungan panel China r tepat untuk Anda adalah dengan mencobanya secara langsung.

5 besar pemasok mesin roll forming atap logam Cina

- Sussman Machinery (Wuxi) Co., Ltd. Shenzhen Hengzhou Yinhong Machinery Co, Ltd mengkhususkan diri dalam pembuatan mesin pembuat gulungan baja dingin sekitar 20 tahun, mengekspor garis menggorok dan bisnis perdagangan internasional seluruh kelompok. Kami memiliki latar belakang teknologi tinggi, peralatan produksi yang maju, pemeriksaan ketat, pekerjaan purna jual yang matang dan layanan yang bijaksana.

- Pengapuran Stamping Forming Machine Manufacture Co, Ltd: Liming Stamping adalah produsen terkemuka lainnya yang mengkhususkan diri dalam produksi mesin roll forming. Mereka menawarkan berbagai model yang cocok untuk produksi panel mobil dan telah memasok mesin mereka ke pasar domestik dan internasional.

- Haixing Industrial Group Co, Ltd: Haixing Industrial Group adalah produsen mesin roll forming yang mapan dan memiliki pengalaman dalam memproduksi mesin roll forming panel mobil. Mereka memiliki berbagai macam produk dan dikenal karena keahlian teknis dan dukungan pelanggan mereka.

- Botou Golden Integrity Roll Forming Machine Co, Ltd: Golden Integrity adalah produsen mesin roll forming yang andal, termasuk mesin roll forming panel mobil. Mereka memiliki kehadiran yang kuat di pasar Cina dan telah mengekspor mesin mereka ke berbagai negara.

- Xiamen Bogong Machinery Manufacturing Co, Ltd: Bogong Machinery adalah produsen profesional mesin roll forming, dan mereka menawarkan berbagai pilihan untuk produksi panel mobil. Mereka telah mendapatkan reputasi yang baik untuk produk berkualitas dan layanan pelanggan yang efisien.

Ulasan

Belum ada ulasan.