Mesin pembuat gulungan bergelombang lembaran logam atap seng Deskripsi:

Mesin Roll Forming Lembaran Atap Seng Lembaran Logam Bergelombang dapat menghasilkan kisaran ketebalan material 0,3-0,8mm atau 0,12-0,4mm, bahan PPGI, baja galvalum dan baja galvanis, juga kami dapat menyesuaikan mesin sesuai dengan gambar Anda, untuk kecepatan mesin, kami dapat melakukan kecepatan normal 8-12m / menit, dikendarai dengan rantai;juga kita dapat melakukan kecepatan tinggi 30-40m / menit, itu digerakkan oleh gearbox, produknya banyak digunakan pada sistem atap dan dinding pada konstruksi bengkel dan konstruksi perumahan.

Desain mesin pembuat gulungan bergelombang lembaran logam atap seng adalah unit satu, yang berarti kotak kontrol dan motor semuanya diletakkan di bawah rangka mesin, ketika Anda mendapatkan mesin, tidak perlu merakit dan menghubungkan kabel mesin yang rumit, Anda hanya perlu menghubungkan satu kabel utama, kemudian mesin bekerja. menghemat lebih banyak waktu dan ruang.

Proses teknologi

Uncoiling—Pengumpan dengan pemandu—Gulungan—Pemotongan—Pengumpulan produk

Daftar mesin

| TIDAK | Nama | kuantitas |

| 1 | 5 ton de-coiler pasif | 1 set |

| 2 | Memberi makan dengan pemandu | 1 set |

| 3 | Mesin pembentuk gulungan utama | 1 set |

| 4 | Kotak kontrol | 1 unit |

| 5 | Pemotongan berhenti secara hidrolik | 1 unit |

| 6 | meja 4 meter keluar | 1 unit |

| 7 | Suku cadang | 1 paket |

| 8 | Penutup pengaman | 1 set |

Data teknis

| Barang NO | Keterangan | Spesifikasi yang ditawarkan |

| 1.1 | Kecepatan bergulir | Sekitar 0-12m / mnt |

| 1.2 | Ketebalan gulungan | 0.3-0.8mm |

| 1.4 | Bahan baku | Gulungan yang dicat warna, lembaran galvanis |

| 1.5 | Motor Utama | 7.5KW |

| 1.6 | Dimensi | Sekitar 9500 × 1600 × 1200 (mm) |

| 1.7 | Stasiun roller | Sekitar 20-22 stasiun

|

| 1.8 | Bahan rol | Baja 45#forge, dilapisi dengan krom |

| 1.9 | Diameter poros | Φ76mm |

| 1.10 | Penularan | Dengan rantai |

| 1.11 | Bahan rantai | Baja tempa 45# dengan pendinginan frekuensi, 12A |

| 1.12 | Bahan pemotongan | Cr12Mov dengan pendinginan HRC58-62° |

| 1.13 | Toleransi | 10m + -1.5mm |

| 1.14 | Stasiun hidrolik | 4kw |

| 1.15 | Panel kendali | PLC dengan layar sentuh, Encoder: Omron, komponen listrik: Schneider |

| 1.16 | Berat mesin | Sekitar 8 ton |

Gambar Profil

Detail tiap komposisi:

1. Buka kuali:

5 ton decoiler pasif

Diameter bagian dalam koil: ¢460-520mm

Max out diameter koil: ¢1500mm

Lebar Kumparan Maks: 1250mm

2. Pemotongan:

(1) Pemotongan setelah pembentukan: Potong lembaran setelah pembentukan gulungan sesuai panjang yang dibutuhkan

(2) Gerakan pemotongan: Mesin utama secara otomatis berhenti dan pemotongan akan berlangsung. Setelah pemotongan, mesin utama akan secara otomatis mulai.

(3) Bahan pisau: CR12Mov dengan perlakuan panas

(4) Pengukuran panjang: Pengukuran panjang otomatis

(5) Toleransi panjang: 10m +/- 1,5mm

3. Tabel keluar:

Ini mengadopsi baja yang dilas dan roller yang didukung untuk mengirimkan produk.

Ukuran:4000*1350*1000mm

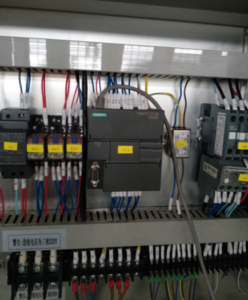

4. Kotak Kontrol:

(1) Pemasok daya: 220V, 60 Hz, 3Fase (disesuaikan dengan permintaan)

(2) pengukuran panjang & kuantitas secara otomatis;

(3) panjang & kuantitas dikendalikan oleh PLC

(4) Ketidaktepatan panjang dapat diubah dengan mudah.

(5) Panel kontrol: Sakelar tipe tombol dan layar sentuh

(6) Satuan panjang: milimeter (diaktifkan pada panel kontrol)

3 Alasan Anda Harus Mempertimbangkan Membeli Mesin Roll Forming Bergelombang untuk dijual

Ulasan

Belum ada ulasan.