Zinc Roof Sheet Metal Corrugated roll forming machine Description:

Zinc Roof Sheet Metal Corrugated Sheet Roll Forming Machine can produce material thickness range 0.3-0.8mm or 0.12-0.4mm, material PPGI, galvalume steel and galvanized steel, also we can customized the machine according to your drawing, for the machine speed, we can do normal speed 8-12m/min, drives by chain; also we can do high speed 30-40m/min, it drives by gearbox, its products are widely used in roof and wall system in workshop construction and housing construction.

Zinc Roof Sheet Metal Corrugated roll forming machine design is unit one, which means the control box and motor are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. it saves more time and space.

Technological process

Uncoiling—Feeding with guide—Roll forming—Cutting—Products collecting

Machine list

| No | Name | quantity |

| 1 | 5 tons passive de-coiler | 1 set |

| 2 | Feeding with guide | 1 set |

| 3 | Main roll forming machine | 1 set |

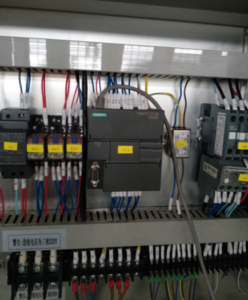

| 4 | Control box | 1 unit |

| 5 | Hydraulic stop cutting | 1 unit |

| 6 | 4 meters out tables | 1 unit |

| 7 | Spare parts | 1 package |

| 8 | Safety cover | 1 set |

Technical Data

| Item NO | Description | Offered specification |

| 1.1 | Rolling speed | About 0-12m/min |

| 1.2 | Rolling thickness | 0.3-0.8mm |

| 1.4 | Raw material | Color painted coils, galvanized sheet |

| 1.5 | Main Motor | 7.5KW |

| 1.6 | Dimension | About 9500×1600×1200(mm) |

| 1.7 | Roller stations | About 20-22 stations

|

| 1.8 | Roller material | 45#forge steel, coated with chrome |

| 1.9 | Shaft diameter | Φ76mm |

| 1.10 | Transmission | By chain |

| 1.11 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.12 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.13 | Tolerance | 10m+-1.5mm |

| 1.14 | Hydraulic station | 4kw |

| 1.15 | Control panel | PLC with touch screen, Encoder:Omron,electric parts:Schneider |

| 1.16 | Machine weight | About 8 tons |

Profile Drawing

Details of each composition:

1.Un-coiler:

5 tons passive decoiler

Coil inner Diameter: ¢460-520mm

Max out diameter of the coil: ¢1500mm

Max Coil Width: 1250mm

2.Cutting:

(1) Cutting after forming: Cut the sheet after roll forming to required length

(2) Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

(3) Material of blade: CR12Mov with heat treatment

(4) Length measuring: Automatic length measuring

(5) Tolerance of length: 10m+/- 1.5mm

3.Out tables:

It adopts welded steel and supported roller to transmit the products.

Size:4000*1350*1000mm

4.Control Box:

(1) Power supplier: 220V, 60 Hz, 3Phase (adjusted with the requestment)

(2) length & quantity measurement automatically;

(3) length & quantity controlled by PLC

(4) Length inaccuracy can be amended easily.

(5) Control panel: Button-type switch and touch screen

(6) Unit of length: millimeter (switched on the control panel)

3 Reasons You Should Consider Buying A corrugated roll forming machine for sale

Reviews

There are no reviews yet.