Introduction

In the realm of modern construction, innovative technologies have revolutionized the way buildings are erected. One such groundbreaking advancement is the light steel frame roll forming machine, a marvel of engineering that streamlines the creation of strong and versatile structures. This article delves into the workings, advantages, applications, types, and maintenance of light steel frame roll forming machines, providing valuable insights for those interested in construction technology.

What is a Light Steel Frame Roll Forming Machine?

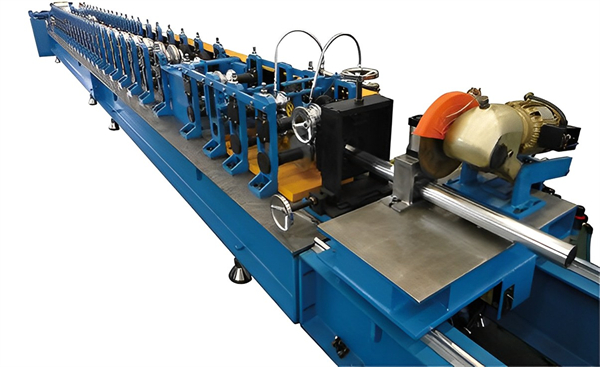

A light steel frame roll forming machine is an automated manufacturing device used to shape light steel coils into precise and customizable profiles. This machine employs a continuous roll forming process, where the steel strip passes through several pairs of rollers to gradually form the desired shape.

How Does a Light Steel Frame Roll Forming Machine Work?

The light steel frame roll forming machine operates through a series of sequential steps. First, the raw material, typically a galvanized or cold-rolled steel coil, is fed into the machine. The rollers then bend and shape the material into the specified profile, while automated cut-off systems ensure accurate length measurements. The finished product is then collected for further processing or assembly.

Advantages of Using Light Steel Frame Roll Forming Machine

Cost-Effective

One of the most significant advantages of using a light steel frame roll forming machine is its cost-effectiveness. The automation and speed of the process significantly reduce labor costs, making it an economical choice for large-scale construction projects.

Quick and Efficient

The high-speed operation of the roll forming machine allows for rapid production, meeting tight project deadlines without compromising on quality.

Versatile Design Options

Light steel frame roll forming machines can create a wide variety of profiles, offering architects and designers the flexibility to innovate and bring their visions to life.

Environmental Friendly

Using light steel in construction has less environmental impact compared to traditional building materials. It is recyclable and contributes to sustainable construction practices.

Durable and Strong Structures

Light steel frames are known for their strength and durability, providing long-lasting and reliable structures for various applications.

Applications of Light Steel Frame Roll Forming Machine

Light steel frame roll forming machines find applications in various construction sectors:

Residential Construction

Light steel frames are used in constructing residential buildings, offering cost-effective, eco-friendly, and earthquake-resistant housing solutions.

Commercial Buildings

The versatility of light steel frames makes them ideal for constructing commercial spaces, providing sturdy structures with large open spaces.

Industrial Structures

In the industrial sector, light steel frames are employed to create warehouses, factories, and other industrial facilities, ensuring durability and safety.

Types of Light Steel Frame Roll Forming Machines

Single-Station Roll Forming Machine

The single-station roll forming machine is suitable for small-scale production and offers straightforward operation and maintenance.

Duplex Roll Forming Machine

The duplex roll forming machine increases productivity by having two separate roll forming stations, enabling the simultaneous formation of two different profiles.

Multi-Station Roll Forming Machine

The multi-station roll forming machine further enhances efficiency by incorporating multiple roll forming stations, suitable for high-volume production.

Factors to Consider when Choosing a Light Steel Frame Roll Forming Machine

Selecting the right light steel frame roll forming machine is crucial for optimal performance and successful project outcomes. Consider the following factors before making a purchase:

Production Capacity

Evaluate the machine’s production capacity to ensure it meets your project requirements. Choose a machine that can handle the desired output without compromising on quality.

Profile Design Options

Check the machine’s capability to create a diverse range of profiles to accommodate different construction needs.

Material Compatibility

Ensure that the roll forming machine is compatible with the type and thickness of steel materials you intend to use.

Automation and Technology Features

Look for advanced features like automatic material feeding, length measurement, and digital control systems for improved efficiency and precision.

Budget and Investment

Understand the initial cost of the machine and consider the long-term return on investment based on its capabilities and productivity.

Maintenance and Care for Light Steel Frame Roll Forming Machine

To ensure the longevity and efficiency of your light steel frame roll forming machine, follow these maintenance practices:

Regular cleaning and inspection of rollers and components to prevent material buildup and potential damages.

Lubricate moving parts and bearings as per manufacturer recommendations to reduce friction and wear.

Train operators to perform routine maintenance and identify early signs of wear or malfunction.

Troubleshooting Common Issues with Light Steel Frame Roll Forming Machine

Despite their reliability, light steel frame roll forming machines may encounter some issues during operation. Here are common problems and troubleshooting tips:

Material Feed Issues

Ensure proper alignment and tension of the material to prevent feeding problems. Clean the feeding system regularly to remove debris.

Profile Distortion

Check for misalignment in the forming rollers or improper material thickness. Adjust the machine settings accordingly.

Roller and Die Wear

Regularly inspect rollers and dies for signs of wear and replace them when necessary to maintain precise profile formation.

Forming Inconsistency

Monitor and calibrate the machine settings to ensure consistent forming throughout the production process.

Tips for Optimal Performance and Productivity

Maximize the efficiency of your light steel frame roll forming machine with these tips:

Regular Inspections and Lubrication

Perform regular inspections and lubricate the machine to minimize friction and reduce wear on moving parts.

Proper Material Handling

Train operators to handle materials carefully to prevent damage and ensure smooth feeding into the machine.

Operator Training and Skill Development

Invest in operator training to improve machine operation and reduce downtime due to operator errors.

Quality Control Measures

Implement stringent quality control processes to ensure that the finished products meet the required standards.

Continuous Improvement Strategies

Regularly assess machine performance and processes to identify areas for improvement and optimize production.

Future Trends in Light Steel Frame Roll Forming Technology

The light steel frame roll forming industry continues to evolve with advancements in technology. Here are some future trends to watch out for:

Integration of Artificial Intelligence

AI-powered systems can optimize machine settings, detect defects, and enhance overall efficiency.

Advanced Material Utilization

Developments in material science will lead to lighter and stronger steel, further improving the performance of light steel frames.

Enhanced Automation and Robotics

Increased automation and robotic systems will streamline the entire manufacturing process, from material handling to packaging.

Environmental Impact of Light Steel Frame Roll Forming Machines

As sustainability becomes a critical concern in construction, light steel frame roll forming machines contribute positively to the environment:

Energy Efficiency

The roll forming process requires less energy compared to other traditional construction methods.

Recyclability of Materials

Steel is highly recyclable, reducing waste and minimizing the environmental footprint of construction projects.

Reduction of Waste

The precise roll forming process minimizes material waste, making it an eco-friendly construction solution.

Case Studies: Successful Implementations of Light Steel Frame Roll Forming Machines

Eco-Friendly Housing Project

A housing project utilized light steel frame roll forming machines to create energy-efficient and sustainable homes, reducing carbon emissions and construction waste.

Rapid Construction of Commercial Spaces

The use of light steel frames allowed for quick and cost-effective construction of large commercial spaces, meeting tight project deadlines.

Sustainable Industrial Structures

An industrial complex implemented light steel frames, achieving a durable and eco-friendly design for its facilities.

Challenges and Limitations of Light Steel Frame Roll Forming Machines

While light steel frame roll forming machines offer numerous advantages, they also face some challenges:

Material Constraints

Availability of suitable steel materials at a reasonable cost can impact the overall viability of projects.

Design Complexity

Complex profile designs may require more advanced and expensive roll forming machines.

Market Awareness and Acceptance

Despite its benefits, the adoption of light steel frame construction in some regions may be hindered by a lack of awareness and acceptance.

Conclusion

The light steel frame roll forming machine has emerged as a game-changer in the construction industry, revolutionizing the way structures are built. Its cost-effectiveness, speed, versatility, and environmental friendliness make it an appealing choice for various construction applications. As technology continues to advance, these machines will play an even more significant role in shaping the future of construction.

FAQs

- Q: What is a light steel frame roll forming machine? A: A light steel frame roll forming machine is an automated manufacturing device used to shape light steel coils into precise and customizable profiles for construction purposes.

- Q: What are the advantages of using a light steel frame roll forming machine? A: Some advantages include cost-effectiveness, quick and efficient production, versatile design options, environmental friendliness, and the creation of durable and strong structures.

- Q: What types of applications are light steel frame roll forming machines suitable for? A: Light steel frame roll forming machines are used in residential, commercial, and industrial construction for various building projects.

- Q: What are the future trends in light steel frame roll forming technology? A: Future trends include the integration of artificial intelligence, advanced material utilization, and enhanced automation and robotics.

- Q: How do light steel frame roll forming machines contribute to the environment? A: They promote sustainability by being energy-efficient, using recyclable materials, and reducing waste in construction.