Машина для профилирования киля Ligh Steel используется для производства одного специального С-образного швеллера, который может применяться для изготовления стеновых, межэтажных и кровельных стропильных конструкций 1-3 этажей жилых домов из легкой стали.

Система автоматически генерирует чертежи изготовления стеновых и напольных панелей, структурные схемы, ведомости раскроя и другие отчеты по материалам. Автоматизация этих процессов позволяет производителям экономить время на составление чертежей, отчетов по материалам, ввод данных, производство и исправление ошибок.

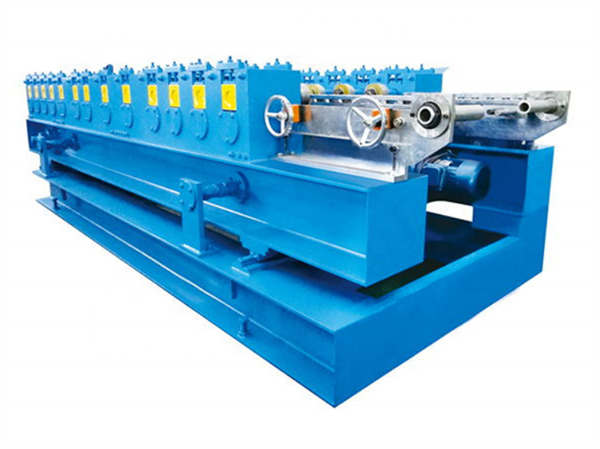

Легкий стальной киль Стальная рамная профилегибочная машина Технические характеристики

| Размер |

89*41 мм, 140*41 мм

|

| Толщина |

0,6-1,2 мм(G300-G550Гальванизированные рулоны и алюцинк )

|

| Ширина подачи | 160 мм, 182 мм |

| Стандартная скорость производства | 450-900 м/ч |

| Максимальная скорость производства | 1500 м/ч |

| Главный мотор |

Серводвигатель мощностью 11 кВт

|

| Поставщик электроэнергии |

380 В 50 Гц 3 фазы в соответствии с Вашим запросом

|

| Гидравлическая станция |

Двигатель Siemens мощностью 7,5 кВт

|

| Емкость гидравлического бака | 100L |

| Гидравлическое охлаждение | Охлаждение вентилятором |

| Гидравлическое давление | Ручная установка |

| Ведущий беспроводной пульт дистанционного управления | Стандарт |

| Рамочные и вырубные штампы |

Винтовое отверстие, фаска, отверстие в полотне 15 мм, фланцевая нарезка, отверстие в трубе 35 мм, подвеска, резка, всего 12 комплектов вырубных штампов

|

| Точность изделия | ±0,5 мм |

| Струйный принтер с ЧПУ | Межструйный принтер |

| Размер |

9080*1450*1600 мм

|

| Масса | 9000 кг |

| Цвет |

в соответствии с Вашим запросом

|

| De-colier |

подшипник 2 тонны, автоматический разматыватель

|

Программное обеспечение Vertex BD Design Software 2021

- Конструкция стен, пола и крыши изготавливается автоматически, что позволяет экономить время проектирования.

- Автоматическое 3D-формование, обеспечивающее точность 100%.

- Благодаря функции анализа проекта программа может рассчитывать несущую способность.

- Создание каркасной 3D-карты и трехмерного декоративного вида.

- Весь каркас здания может быть решен в виде самостоятельного чертежа.

- Рассчитайте спецификацию материалов, включая необходимую сталь, листы, теплоизоляционный материал, двери и окна, шурупы и другие подходящие материалы.

- Создание обработанных данных, включающих размеченную заготовку, стыковку с оборудованием.

- Плата за сопровождение программного обеспечения и обучение.

- Стоимость обслуживания и поддержки составляет 2200,00 долл. в год. Она предназначена для обновления программного обеспечения и является дополнительной.

Путеводитель по лучшей машине для производства килевых профилей из легкой стали?

Что такое килевая валковая формовочная машина

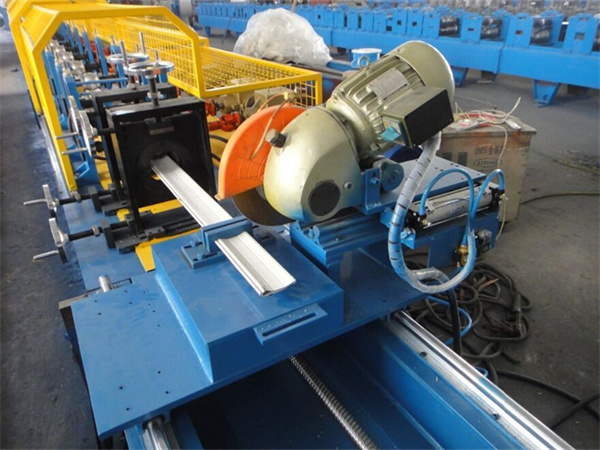

Килевая вальцовочная машина - это специализированное оборудование, используемое в строительстве для производства металлических шпилек и направляющих. Он работает по принципу подачи металлической полосы через ролики, которые формируют из нее П-образные шпильки и С-образные направляющие. Машина автоматизирована и состоит из разматывателей, систем выравнивания, станций формирования роликов, устройств резки и систем управления. Он позволяет эффективно и точно изготавливать легкие и прочные металлические элементы каркаса, используемые в различных строительных конструкциях.

что такое машина для формирования киля из легкой стали

Станок для формовки килей из легкой стали - это специализированное оборудование, используемое в строительной отрасли для производства килевых профилей из легкой стали. Легкие стальные кили, также известные как легкие стальные стойки или легкие стальные каркасы, представляют собой легкие стальные элементы, используемые при возведении внутренних стен, потолков и других ненесущих конструкций.

В качестве исходного материала для валковой формовки используются плоские полосы рулонной оцинкованной стали, которые проходят через ряд роликов. Эти ролики постепенно придают стали требуемый профиль, который обычно представляет собой С-образный или U-образный канал. Ролики имеют специальные контуры и размеры, обеспечивающие точную и последовательную формовку стали.

В состав станка обычно входят различные компоненты, такие как разматыватель для удержания рулонной стали, выравнивающее устройство для выпрямления рулона, система перфорации для создания отверстий или пазов в килевых профилях, а также режущий механизм для резки профилей на отрезки необходимой длины. Некоторые машины могут иметь дополнительные функции, такие как тиснение или перфорирование, для повышения универсальности производимых килевых профилей.

Валковые машины для формовки килей из легкой стали - это эффективные и высокоскоростные машины, способные непрерывно производить большое количество килевых профилей. Получаемые килевые профили легки, прочны и удобны в обращении, что делает их востребованными в современных строительных проектах.

лучшие 5 легкие килевые роликовые формовочные машины завод в Китае

- Sussman Machinery (Wuxi) Co., Ltd.

- Xiamen Liming Machinery Co., Ltd.

- Shanghai Believe Industry Co., Ltd.

- Компания Cangzhou ZHONGTUO International Trade Co., Ltd.

- Компания Botou Kexinda Roll Forming Machine Co., Ltd.

На что следует обратить внимание при изготовлении килевых валков на заказ?

- Четко сформулируйте свои требования, включая формы, размеры и материалы профилей.

- Убедитесь, что станок совместим с необходимой толщиной и шириной материала.

- Определите требуемую производственную мощность и уровень автоматизации.

- Обсудить возможности настройки, такие как перфорация или выемка.

- Проверьте репутацию производителя на предмет качества и надежности.

- Узнайте о послепродажной поддержке, запасных частях и гарантийном обслуживании.

- Сбалансируйте возможности настройки с бюджетными ограничениями.

Эффективная коммуникация и сотрудничество с производителем являются залогом успешного процесса кастомизации.

преимущества китайской машины для формирования киля из легкой стали

- Экономически эффективное производство: Станки для формовки килей из легкой стали, произведенные в Китае, часто являются экономически эффективными производственными решениями. Эти машины предназначены для оптимизации эффективности, сокращения отходов материалов и рационализации производственного процесса, что приводит к снижению себестоимости продукции.

- Варианты персонализации: Китайские производственные мощности позволяют изготавливать машины для формовки килей из легкой стали по индивидуальным заказам. Производители могут адаптировать машины к конкретным требованиям заказчика, включая различные формы профилей, размеры и типы материалов, что обеспечивает универсальность для различных областей применения в строительстве.

- Высокая эффективность производства: Китайские станки для формовки килей из легкой стали рассчитаны на высокую эффективность производства. Благодаря автоматизированным процессам, точным методам формовки и высокой скорости производства эти машины могут удовлетворять требованиям крупносерийного производства, сохраняя при этом неизменное качество и точность.

- Надежность работы: Китай имеет устойчивую репутацию производителя надежных и долговечных вальцовочных станков. Производители часто придерживаются строгих стандартов контроля качества и применяют передовые технологии производства, что обеспечивает надежность и долговечность оборудования.

- Передовые технологии и инновации: Китайская промышленность по производству валковых машин использует передовые технологии и инновации. Многие китайские производители внедряют в свои валковые машины для формовки килей из легкой стали современные системы управления, серводвигатели и другие передовые технологии, повышающие точность, эффективность и удобство эксплуатации.

- Оперативная послепродажная поддержка: Китайские производители, как правило, обеспечивают оперативную послепродажную поддержку, включая техническую помощь, обучение персонала и наличие запасных частей. Это обеспечивает бесперебойную работу оборудования, сокращает время простоя и повышает общую удовлетворенность клиентов.

- Широкое присутствие на рынке: Благодаря развитому китайскому производственному сектору, китайские станки для формовки килей из легкой стали занимают значительное место на мировом рынке. Такое широкое присутствие на рынке способствует развитию конкуренции, стимулирует технический прогресс и предоставляет заказчикам различные возможности для выбора.

Отзывы

Отзывов пока нет.