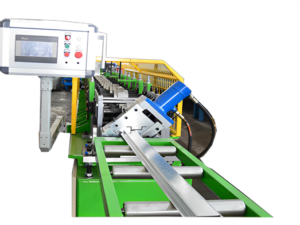

Ligh Steel keel roll forming machine is used to produce one special C channel profile which can be used for 1-3 floors light gauge steel residence wall, floor and roof truss structures.

The sysmte automatic generates wall and floor panel fabrication drawings, structural layouts, cut lists, and other material reports. By automating these processes, manufacturers are saving lots of time in drafting, material reporting, data entry, manufacturing, and correcting all the errors.

Light steel keel Steel framing roll forming machine Specifications

| Size |

89*41mm, 140*41mm

|

| Thickness |

0.6-1.2mm(G300-G550Galvanzied coils and Aluzinc )

|

| Feeding width | 160mm, 182mm |

| Standard Producing speed | 450-900m/h |

| Max producing speed | 1500m/h |

| Main motor |

11kw Servo motor

|

| Power supplier |

380V 50Hz 3 phases according to your request

|

| Hydraulic station |

7.5kw Siemens Motor

|

| Hydraulic tank capacity | 100L |

| Hydraulic cooling | Fan cooling |

| Hydraulic pressure | Manually set |

| Host cordless remote control | Standard |

| Frame and punching dies |

Screw hole, chamfer, 15mm web hole, flange cut, 35mm pipe hole, suspension, cutting, total 12 sets of punching dies

|

| Product accuracy | ±0.5mm |

| CNC inkjet-printer | Inter jet printer |

| Size |

9080*1450*1600mm

|

| Weight | 9000kg |

| Color |

according to your request

|

| De-colier |

bearing 2 tonnes, automatical decoiler

|

Vertex BD Design Software 2021

- The wall, floor and roof structure is produced automatically, saving design time.

- Automatic 3D molding, insure 100% accuracy.

- With analysis project function, the software can calculate bearing capacity.

- Create framework 3D map and 3D decoration view.

- The whole building frame can be resolved to independent unit drawing.

- Calculate the bill of material, including the needed steel, plates, thermal insulation material, doors and windows, screws and other matching material.

- Create the processed data including the marked work piece, docking with the equipment.

- Software maintenance and training fee.

- Maintenance and supporting fee is USD2200.00/Year. It’s for software update and optional.

what is Keel roll forming machine

A keel roll forming machine is a specialized equipment used in construction to produce metal studs and tracks. It operates by feeding a metal strip through rollers that shape it into U-shaped studs and C-shaped tracks. The machine is automated and consists of decoilers, leveling systems, roll forming stations, cutting devices, and control systems. It enables efficient and precise manufacturing of lightweight and durable metal framing components used in various building structures.

what is light steel keel roll forming machine

A light steel keel roll forming machine is a specialized piece of equipment used in the construction industry to produce light steel keel profiles. Light steel keels, also known as light steel studs or light gauge steel framing, are lightweight, steel-based components used in the construction of interior walls, ceilings, and other non-load-bearing structures.

The roll forming machine takes flat strips of galvanized steel coil as input material and passes them through a series of rollers. These rollers progressively shape the steel into the desired profile, which typically consists of a C-shaped or U-shaped channel. The rollers are designed with specific contours and dimensions to ensure precise and consistent shaping of the steel.

The machine usually includes various components, such as a decoiler to hold the steel coil, a leveling device to straighten the coil, a punching system to create holes or slots in the keel profiles, and a cutting mechanism to cut the profiles to the required length. Some machines may also have additional features, such as embossing or perforating capabilities, to enhance the versatility of the produced keel profiles.

Light steel keel roll forming machines are efficient and high-speed machines that can produce large quantities of keel profiles in a continuous manner. The resulting keel profiles are lightweight, durable, and easy to handle, making them popular in modern construction projects.

best 5 light keel roll forming machine factory in China

- Sussman Machinery(Wuxi)Co., Ltd.

- Xiamen Liming Machinery Co., Ltd.

- Shanghai Believe Industry Co., Ltd.

- Cangzhou ZHONGTUO International Trade Co., Ltd.

- Botou Kexinda Roll Forming Machine Co., Ltd.

what need pay attention to customized keel roll forming machine?

- Specify your requirements clearly, including profile shapes, sizes, and materials.

- Ensure the machine is compatible with the material thickness and width needed.

- Determine the desired production capacity and automation level.

- Discuss customization options like punching or notching features.

- Verify the manufacturer’s reputation for quality and reliability.

- Inquire about after-sales support, spare parts, and warranty coverage.

- Balance customization features with your budget constraints.

Effective communication and collaboration with the manufacturer are essential for a successful customization process.

benefit of china light steel keel roll forming machine

- Cost-Effective Production: Light steel keel roll forming machines manufactured in China often provide cost-effective production solutions. These machines are designed to optimize efficiency, reduce material waste, and streamline the manufacturing process, resulting in lower production costs.

- Customization Options: China’s manufacturing capabilities allow for a wide range of customization options in light steel keel roll forming machines. Manufacturers can tailor the machines to specific customer requirements, including different profile shapes, sizes, and material types, providing versatility for various construction applications.

- High Production Efficiency: Light steel keel roll forming machines from China are engineered for high production efficiency. With automated processes, precise forming techniques, and fast production speeds, these machines can meet high-volume production demands while maintaining consistent quality and accuracy.

- Reliable Performance: China has a well-established reputation for producing reliable and durable roll forming machines. Manufacturers often adhere to stringent quality control standards and employ advanced manufacturing technologies to ensure reliable performance and longevity of the machines.

- Advanced Technology and Innovation: China’s roll forming machine industry has embraced technological advancements and innovations. Many manufacturers in China incorporate advanced control systems, servo motors, and other cutting-edge technologies into their light steel keel roll forming machines, enhancing precision, efficiency, and ease of operation.

- Responsive After-Sales Support: Chinese manufacturers typically provide responsive after-sales support, including technical assistance, training, and spare parts availability. This ensures smooth machine operation, reduces downtime, and enhances overall customer satisfaction.

- Wide Market Presence: Due to China’s robust manufacturing sector, light steel keel roll forming machines from China have a significant market presence worldwide. This wide market presence fosters competition, encourages technological advancements, and provides customers with various options to choose from.

Reviews

There are no reviews yet.