1. Introduction

In the world of modern manufacturing and construction, efficiency and precision are paramount. One significant advancement that has revolutionized various industries is the silo roll forming machine. This powerful and versatile equipment is used to fabricate silos of different sizes and shapes with exceptional accuracy. This article will delve into the details of the silo roll forming machine, its types, applications, advantages, key components, maintenance tips, and more.

2. What is a Silo Roll Forming Machine?

A silo roll forming machine is a specialized piece of equipment used in the manufacturing process of silos. Silos are cylindrical storage structures that are widely used in industries like agriculture, food processing, chemicals, and construction to store bulk materials such as grains, cement, chemicals, and more. The roll forming machine takes flat metal coils and shapes them into precise and seamless silo panels, ready for assembly.

3. Types of Silo Roll Forming Machines

Silo roll forming machines come in various types, each designed for specific silo profiles. The common types include:

3.1 Spiral Silo Roll Forming Machine

The spiral silo roll forming machine is used to create spiral-shaped silo panels, which are known for their high strength and smooth surface finish.

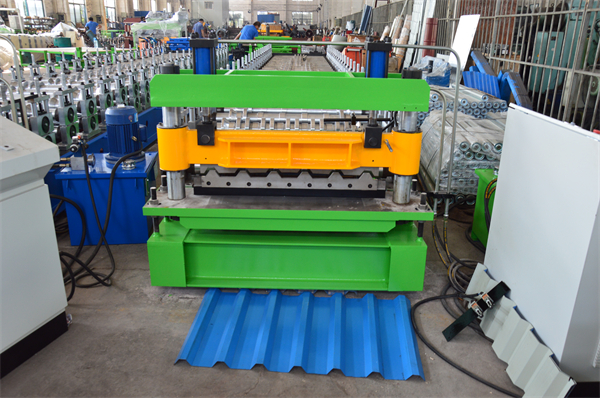

3.2 Corrugated Silo Roll Forming Machine

The corrugated silo roll forming machine produces silo panels with corrugations, providing added structural stability and enhancing load-bearing capacity.

3.3 Welded Silo Roll Forming Machine

The welded silo roll forming machine fabricates silo panels that are welded together, resulting in a seamless and leak-proof silo structure.

4. Advantages of Using Silo Roll Forming Machines

Using a silo roll forming machine offers several advantages, including:

4.1 Increased Efficiency

The automated process of the roll forming machine ensures a high production rate, reducing manual labor and overall production time.

4.2 Cost-effectiveness

By streamlining the manufacturing process and reducing material waste, silo roll forming machines contribute to cost-effectiveness in the long run.

4.3 Customization Options

Silo roll forming machines can be adjusted to create silos of different sizes and designs, catering to the specific needs of different industries.

4.4 Durability and Strength

The precise shaping of silo panels ensures uniformity and strength, resulting in durable and long-lasting silos.

5. Applications of Silo Roll Forming Machines

Silo roll forming machines find applications in various industries, including:

5.1 Agriculture Industry

In the agriculture industry, silo roll forming machines are used to create grain storage silos, preserving crops efficiently.

5.2 Food Processing Industry

Food processing plants utilize silo roll forming machines to fabricate silos for storing ingredients like flour, sugar, and more.

5.3 Chemical Industry

The chemical industry employs silo roll forming machines to produce storage containers for bulk chemicals and powders.

5.4 Construction Industry

In the construction sector, silo roll forming machines play a vital role in producing silos for cement and other construction materials.

6. Key Components of a Silo Roll Forming Machine

A silo roll forming machine comprises several essential components that work together to create precise silo panels. These components include:

6.1 Decoiler

The decoiler holds the metal coil and feeds it into the roll forming machine, ensuring a continuous and smooth production process.

6.2 Feeding and Leveling System

This system ensures the proper alignment and leveling of the metal coil before it enters the roll forming unit.

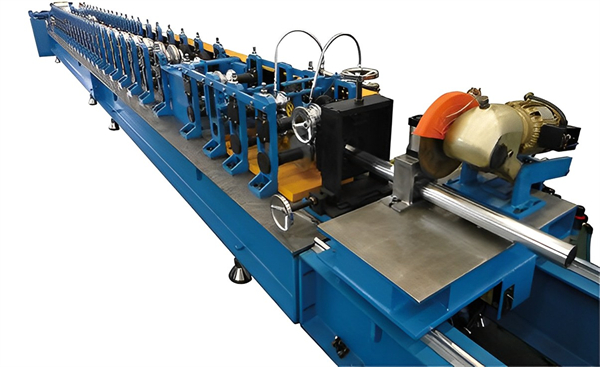

6.3 Roll Forming Unit

The roll forming unit is the heart of the machine, where the metal coil is shaped into the desired profile using a series of rollers.

6.4 Cutting System

Once the silo panels are formed to the required length, the cutting system precisely cuts them, ready for assembly.

6.5 Control System

The control system, often computerized, oversees the entire production process, allowing operators to adjust settings and monitor performance.

7. Factors to Consider When Choosing a Silo Roll Forming Machine

Selecting the right silo roll forming machine for specific requirements involves considering various factors, such as:

7.1 Production Capacity

Determining the desired production output is crucial to ensure the machine meets production demands.

7.2 Material Thickness and Width

The machine’s capacity to handle different material thicknesses and widths affects the range of silo profiles that can be produced.

7.3 Machine Size and Space Requirements

Considering the available space in the production facility is essential to accommodate the machine and facilitate its operation.

7.4 Automation and Technology Integration

The level of automation and technology integration can impact production efficiency and ease of operation.

8. Maintenance and Safety Tips for Silo Roll Forming Machines

To ensure optimal performance and longevity, regular maintenance and adherence to safety protocols are essential. Some tips include:

8.1 Regular Maintenance Schedule

Establish a routine maintenance schedule to inspect, clean, and service the machine components.

8.2 Lubrication and Cleaning

Keep the moving parts well-lubricated and clean to prevent wear and tear and ensure smooth operation.

8.3 Safety Measures

Train operators on proper safety protocols and equip the machine with safety features like emergency stop buttons.

8.4 Training and Operator Knowledge

Ensure that operators are adequately trained to operate the machine and troubleshoot common issues.

9. How to Optimize the Production Process with Silo Roll Forming Machines

To achieve maximum efficiency in the production process, consider the following optimization steps:

9.1 Material Handling and Preparation

Ensure proper handling and preparation of metal coils to minimize material waste and downtime.

9.2 Machine Setup and Calibration

Precise machine setup and calibration lead to accurate silo panel production and reduced rework.

9.3 Continuous Production Monitoring

Regularly monitor the machine’s performance and product quality to identify and address any potential issues promptly.

9.4 Quality Control and Inspection

Implement quality control measures to ensure that all silo panels meet the required standards before assembly.

10. Future Trends and Innovations in Silo Roll Forming Technology

The field of roll forming technology continues to evolve, with ongoing innovations in automation, materials, and design.

11. Case Studies: Successful Implementation of Silo Roll Forming Machines

Examine real-life examples of industries that have successfully integrated silo roll forming machines into their production processes.

12. Conclusion

The silo roll forming machine has revolutionized various industries by offering efficient, cost-effective, and precise silo fabrication solutions. Its flexibility, customization options, and durability make it an indispensable tool in the modern manufacturing and construction landscape.

FAQs

1. What materials are commonly used in silo roll forming machines?

Silo roll forming machines typically work with materials like galvanized steel, stainless steel, and aluminum.

2. Can a silo roll forming machine produce silos of different capacities?

Yes, silo roll forming machines can be adjusted to create silos of various capacities, catering to specific requirements.

3. Are silo roll forming machines suitable for small-scale operations?

Yes, silo roll forming machines can be used for both small-scale and large-scale production, thanks to their customization options.

4. How long does it take to set up a silo roll forming machine for a new production run?

The setup time depends on factors such as the complexity of the silo profile and the operator’s familiarity with the machine. It can range from a few minutes to an hour.

5. Can a silo roll forming machine create silos with special features, such as insulation?

Yes, advanced silo roll forming machines can be equipped with additional features, such as insulation application during the forming process.