1. Introduction

When it comes to roofing, it’s essential to ensure that all components are of high quality and provide adequate protection. One crucial element of a well-constructed roof is the ridge cap. Ridge caps are the angled covers placed at the peak of a roof to protect it from water, wind, and other environmental factors. To manufacture these ridge caps efficiently, ridge cap roll forming machines come into play. In this article, we will delve into the details of ridge cap roll forming machines, their working principle, benefits, and how to choose the right one for your roofing needs.

2. What is a Ridge Cap?

Before understanding the role of a ridge cap roll forming machine, let’s first grasp the concept of a ridge cap itself. A ridge cap is a specialized roofing accessory that covers the intersection where two roof slopes meet. It forms a protective seal that prevents water, debris, and pests from entering the roof’s vulnerable areas. Ridge caps are usually made from durable materials such as metal or asphalt shingles and are available in various shapes and sizes to match different roofing profiles.

3. Importance of Ridge Caps

Ridge caps play a vital role in the overall durability and longevity of a roof. Here are a few key reasons why ridge caps are essential:

- Weather Protection: Ridge caps act as a barrier against weather elements, including rain, snow, and strong winds. They help prevent water seepage and protect the underlying structure of the roof.

- Enhanced Ventilation: Ridge caps are designed to allow proper ventilation in the attic or roof space. This ventilation helps regulate temperature and humidity levels, preventing the formation of mold and preserving the integrity of the roof.

- Aesthetic Appeal: Ridge caps give a finished look to the roof by covering the exposed edges. They enhance the overall appearance of the roof and add to its curb appeal.

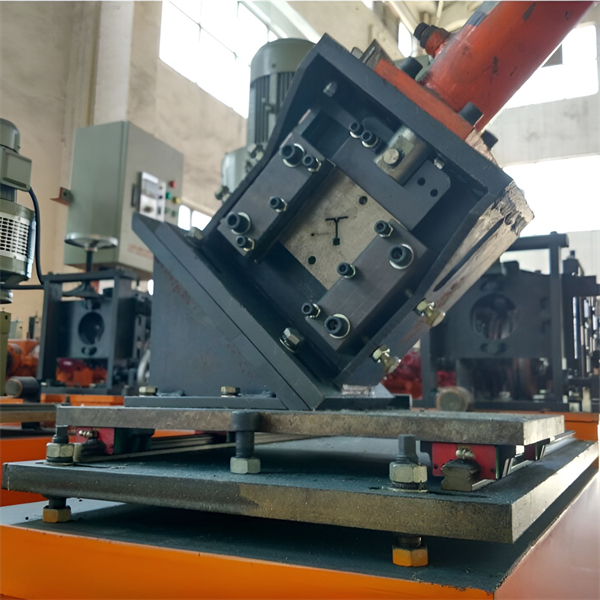

4. Ridge Cap Roll Forming Machine: An Overview

A ridge cap roll forming machine is a specialized equipment used to manufacture ridge caps in a precise and efficient manner. These machines are designed to shape and cut metal coils into custom ridge cap profiles. By utilizing a continuous roll forming process, they can produce ridge caps with consistent dimensions and excellent dimensional accuracy. Ridge cap roll forming machines are commonly used in roofing manufacturing facilities, construction companies, and metal fabrication workshops.

5. Working Principle of Ridge Cap Roll Forming Machine

The working principle of a ridge cap roll forming machine involves several sequential steps. Let’s explore the typical operation process:

- Material Loading: The machine operator feeds the metal coil onto the machine, ensuring it is properly aligned.

- Roll Forming: The machine’s rollers gradually shape the metal coil into the desired ridge cap profile. The metal passes through a series of forming stations that bend and shape it according to the predetermined design.

- Cutting: Once the ridge cap profile is formed, the machine automatically cuts the metal coil to the required length. This ensures precise and consistent ridge caps.

- Stacking and Packaging: The finished ridge caps are stacked and packaged, ready for transportation and installation.

6. Benefits of Using a Ridge Cap Roll Forming Machine

Using a ridge cap roll forming machine offers several advantages:

- High Efficiency: These machines can produce ridge caps at a rapid pace, significantly reducing production time and increasing overall efficiency.

- Customization: Ridge cap roll forming machines allow for the creation of various ridge cap profiles, enabling customization based on specific roofing requirements.

- Consistency and Precision: The continuous roll forming process ensures consistent dimensions and precise shaping, resulting in ridge caps with high quality and dimensional accuracy.

- Cost-effective: By automating the production process, ridge cap roll forming machines minimize labor costs and material wastage, making them a cost-effective solution for large-scale ridge cap manufacturing.

- Ease of Operation: Modern ridge cap roll forming machines are user-friendly, with intuitive controls and automated functions. They require minimal operator training and supervision.

7. Factors to Consider When Choosing a Ridge Cap Roll Forming Machine

When selecting a ridge cap roll forming machine, it’s crucial to consider the following factors:

- Production Capacity: Determine the required production volume to choose a machine that can meet your output requirements.

- Material Compatibility: Ensure that the machine is suitable for the type and thickness of the metal coil you plan to use for manufacturing ridge caps.

- Profile Flexibility: Assess the machine’s capability to produce various ridge cap profiles, allowing versatility for different roofing projects.

- Machine Size and Space: Consider the available space in your facility and choose a machine size that fits comfortably within your production area.

- Manufacturer Reputation: Research and choose a reliable and reputable manufacturer known for producing high-quality roll forming machines with excellent after-sales support.

8. Types of Ridge Cap Roll Forming Machines

There are different types of ridge cap roll forming machines available in the market, designed to cater to various roofing needs. Some common types include:

- Single Station Roll Forming Machines: These machines are suitable for low to medium production volumes and produce ridge caps in a single pass.

- Continuous Roll Forming Machines: Continuous roll formers are ideal for high-volume ridge cap production. They offer faster production speeds and can produce ridge caps with complex profiles.

- Portable Roll Forming Machines: Portable roll formers are designed for on-site ridge cap manufacturing. They are compact and easy to transport, allowing flexibility for remote construction projects.

9. Features to Look for in a Ridge Cap Roll Forming Machine

To ensure optimal performance and longevity, consider the following features when choosing a ridge cap roll forming machine:

- Heavy-Duty Construction: Look for a machine made from durable materials and components that can withstand the rigors of continuous operation.

- Adjustability: The machine should offer flexibility to adjust settings such as ridge cap dimensions, forming speed, and cutting length.

- Automation and Control: Choose a machine equipped with advanced automation and control systems for ease of operation and accurate ridge cap production.

- Safety Features: Prioritize machines with safety mechanisms like emergency stop buttons, protective covers, and sensors to prevent accidents during operation.

- Maintenance and Support: Ensure the manufacturer provides comprehensive maintenance guidelines and offers prompt technical support and spare parts availability.

10. Steps to Operate a Ridge Cap Roll Forming Machine

Operating a ridge cap roll forming machine involves the following steps:

- Setup: Adjust the machine settings, such as the ridge cap dimensions and desired production speed, according to the specifications of the roofing project

- Material Loading: Load the metal coil onto the machine, ensuring it is properly aligned and securely held in place.

- Machine Start-up: Power on the machine and initiate the roll forming process. Ensure all safety measures are in place before starting the operation.

- Monitor Operation: Keep a close eye on the machine’s performance, checking for any abnormalities or malfunctions. Monitor the quality and accuracy of the produced ridge caps.

- Quality Control: Regularly inspect the ridge caps for dimensional accuracy, shape consistency, and overall quality. Make adjustments to the machine settings if necessary.

- Cutting and Stacking: Once the ridge caps are formed to the desired length, the machine will automatically cut them. Collect the finished ridge caps and stack them for packaging.

- Packaging and Labeling: Properly package the ridge caps to protect them during transportation and storage. Label the packages for easy identification and traceability.

- Maintenance and Cleaning: Regularly clean and maintain the machine according to the manufacturer’s guidelines. This ensures optimal performance and extends the machine’s lifespan.

11. Maintenance and Care of Ridge Cap Roll Forming Machine

To ensure the longevity and efficient operation of your ridge cap roll forming machine, it’s essential to follow proper maintenance and care practices. Here are some key steps:

- Regular Cleaning: Clean the machine after each production cycle to remove debris, dust, and metal shavings. Use appropriate cleaning tools and ensure all areas are thoroughly cleaned.

- Lubrication: Apply lubricants to the moving parts of the machine as recommended by the manufacturer. This reduces friction, prevents wear and tear, and ensures smooth operation.

- Inspection and Repair: Regularly inspect the machine for any signs of damage, loose components, or abnormalities. Promptly address any issues by repairing or replacing the affected parts.

- Calibration: Periodically check and calibrate the machine’s settings, such as forming dimensions and cutting length. This ensures consistent and accurate ridge cap production.

- Operator Training: Provide proper training to machine operators on the correct operation, safety procedures, and routine maintenance tasks. This empowers them to handle the machine effectively and safely.

- Scheduled Maintenance: Follow the manufacturer’s recommended maintenance schedule for comprehensive servicing and inspections. This includes checking electrical connections, hydraulic systems, and other critical components.

By adhering to these maintenance practices, you can optimize the performance and lifespan of your ridge cap roll forming machine, ensuring smooth and efficient operation for years to come.

12. Common Issues and Troubleshooting

While ridge cap roll forming machines are designed for reliable performance, occasional issues may arise. Here are some common problems and possible troubleshooting steps:

- Misshapen Ridge Caps: If the formed ridge caps have irregular shapes or dimensions, check the alignment of the rollers and ensure they are properly adjusted. Verify that the material is feeding smoothly through the machine without any obstructions.

- Uneven Ridge Cap Length: Inconsistent ridge cap lengths can result from improper cutting. Verify that the cutting mechanism is functioning correctly and adjust the cutting settings if needed.

- Machine Jams: If the machine gets jammed during operation, immediately stop the machine and carefully remove the jammed material. Inspect for any bent or damaged components that may have caused the jam.

- Excessive Noise or Vibration: Unusual noise or vibration can indicate loose or worn-out parts. Inspect and tighten any loose connections or bolts. Replace any damaged or worn-out components as necessary.

If troubleshooting steps do not resolve the issues, consult the manufacturer’s manual or seek assistance from their technical support team.

13. Safety Precautions for Using a Ridge Cap Roll Forming Machine

Safety should always be a top priority when operating a ridge cap roll forming machine. Follow these safety precautions to minimize the risk of accidents:

- Operator Training: Ensure that all machine operators are trained in safe operating procedures, including emergency stop protocols and proper handling of the machine.

- Protective Gear: Operators should wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and ear protection, to safeguard against potential hazards.

- Machine Guarding: Ensure that all moving parts of the machine are properly guarded with protective covers. This prevents accidental contact with the rollers, cutting mechanisms, and other hazardous areas.

- Emergency Stop: Install easily accessible emergency stop buttons or switches near the machine so that operators can quickly halt the operation in case of emergencies or malfunctions.

- Proper Material Handling: Follow safe material handling practices to prevent injuries. Use lifting equipment or tools to load and unload metal coils, avoiding manual lifting or excessive strain.

- Regular Inspections: Conduct routine inspections of the machine to identify any safety hazards or potential issues. Repair or replace faulty parts promptly to maintain a safe working environment.

By implementing these safety precautions, you can ensure the well-being of operators and minimize the risk of accidents during the operation of a ridge cap roll forming machine.

14. Applications of Ridge Cap Roll Forming Machines

Ridge cap roll forming machines find extensive applications in the roofing industry and construction sector. Here are some key areas where these machines are utilized:

- Residential Roofing: Ridge cap roll forming machines are commonly used to manufacture ridge caps for residential roofs, ensuring optimal weather protection and aesthetic appeal.

- Commercial and Industrial Roofing: Large-scale roofing projects, such as commercial buildings and industrial facilities, rely on ridge cap roll forming machines to produce ridge caps efficiently and cost-effectively.

- Architectural Projects: Ridge cap roll forming machines are essential in architectural projects that require customized ridge cap profiles to match specific design requirements.

- Roofing Material Manufacturing: Manufacturers of roofing materials and components utilize ridge cap roll forming machines as a part of their production process to ensure consistent quality and high-volume output.

The versatility and efficiency of ridge cap roll forming machines make them a valuable asset in the construction and roofing industry, contributing to the creation of durable and aesthetically pleasing roofs.

15. Future Trends in Ridge Cap Roll Forming Technology

As technology continues to advance, several trends are shaping the future of ridge cap roll forming machines:

- Automation and Integration: Future machines are expected to have advanced automation features, integrating robotics and artificial intelligence to enhance productivity and reduce human intervention.

- Energy Efficiency: Manufacturers are working towards developing energy-efficient machines by optimizing power consumption and incorporating eco-friendly components and technologies.

- Advanced Control Systems: Improved control systems will offer greater precision and flexibility in ridge cap production, allowing for customization and quick adjustments to meet changing market demands.

- Smart Maintenance and Diagnostics: Future machines may incorporate smart sensors and diagnostic tools to monitor machine health, predict maintenance needs, and proactively address issues.

- Material Innovation: The development of new lightweight and durable materials for ridge caps may influence the design and capabilities of future roll forming machines, enabling the production of more sustainable and efficient roofing solutions.

By embracing these trends, the ridge cap roll forming industry is poised to evolve and meet the demands of modern roofing technologies and construction practices.

16. Conclusion

Ridge cap roll forming machines play a crucial role in the efficient production of ridge caps, ensuring durable and weather-resistant roofing solutions. By understanding their working principle, benefits, and key considerations, you can make informed decisions when choosing a machine for your specific requirements. Remember to prioritize safety, implement proper maintenance practices, and stay updated with the latest trends in roll forming technology. With the right approach and a reliable ridge cap roll forming machine, you can streamline your ridge cap manufacturing process, enhance productivity, and deliver high-quality roofing solutions.

FAQs

1. Are ridge caps necessary for every type of roof?

Yes, ridge caps are essential for most types of roofs. They provide protection against water infiltration, enhance ventilation, and give a finished look to the roof.

2. Can ridge caps be customized to match different roof designs?

Yes, ridge cap roll forming machines offer the flexibility to produce ridge caps in various profiles, allowing customization to match different roof designs and architectural styles.

3. What is the typical production capacity of a ridge cap roll forming machine?

The production capacity of a ridge cap roll forming machine varies depending on its size, speed, and design complexity. Machines can range from producing a few hundred ridge caps per hour to thousands of ridge caps per hour.

4. How long do ridge cap roll forming machines last?

The lifespan of a ridge cap roll forming machine depends on various factors such as maintenance, usage, and quality of components. With proper care and regular maintenance, a well-built machine can last for many years.

5. Can ridge cap roll forming machines work with different types of metals?

Yes, ridge cap roll forming machines are designed to work with various metals, including steel, aluminum, and copper. The machine specifications should match the type and thickness of the metal coil you intend to use.