Aluzinc PPGI roof ridge cap roll forming machine can produce material thickness range 0.3-0.8mm, material PPGI, galvalume steel and galvanized steel, also we can customize the machine according to your drawing.

Aluzinc PPGI roof ridge cap roll forming machine design is unit one, which means the control box and motor are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. It saves more time and space.

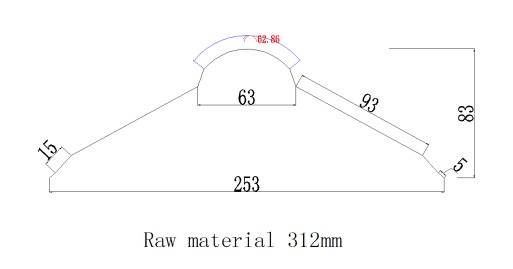

Profile Drawing of Aluzinc PPGI roof ridge cap roll forming machine

Technological Process

Uncoiling—Feeding with guide—Roll forming—cutting—Products collecting

|

Machine list

|

3 tons passive de-coiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| PLC Control box | 1 unit | |

| Hydraulic station | 1 unit | |

| Hydraulic cutting | 1 unit | |

| Out tables | 2 units | |

| Safety cover | 1 set |

Technical Data

| Item NO | Description |

Offered specification

|

| 1 | Rolling speed |

10-15m/min(not include cutting time)

|

| 2 | Rolling thickness | 0.3-0.6mm |

| 3 | Raw material |

Galvanized steel sheet

|

| 6 | Dimension |

About 7500×1000×1200(mm)

|

| 7 | Weight | About 6 tons |

| 8 | Roller stations |

About 16 stations

|

| 9 | Roller material |

45#forge steel, coated with chrome

|

| 10 | Shaft diameter |

Φ70mm, material is 45# forge steel

|

| 11 | Transmission |

By chain 1 inch

|

| 12 | Material of chain |

45# forged steel with frequency quenching, 12A

|

| 14 | Material of cutting |

Cr12Mov with quench HRC58-62°

|

| 15 | Tolerance | 6m+-5mm |

| 16 | Frame | H type steel |

Details Of Each Composition

1. 3T passive De-coiler

- Coil inner Diameter: ¢460mm~520mm

- Max out diameter of the coil: ¢800mm

- Expansion: with 4 palms, with brake

- Max Coil Width: 500mm

2. Cutting

(1) Cutting after forming: Cut the sheet after roll forming to required length

(2) Cutting motion: The main machine automatically stops, and the cutting will take place. After the cutting, the main machine will automatically start.

(3) Material of blade: CR12Mov with heat treatment

(4) Length measuring: Automatic length measuring

(5) Tolerance of length: 10m±2mm

3. Out tables

- Length: 2 meters

- Number: 2 units

4. Control Box

(1) Power supplier: 380 V, 50 Hz, 3Phase (adjusted with the requestment)

(2) Length & quantity measurement automatically;

(3) Length & quantity controlled by PLC

(4) Length inaccuracy can be amended easily.

(6). Control panel: Button-type switch and touch screen

(7) Unit of length: millimeter (switched on the control panel)

What is capping roll forming machine?

A capping roll forming machine is a type of industrial machinery used in the manufacturing process of capping profiles or strips. It is commonly used in industries such as construction, automotive, and appliance manufacturing.

The roll forming process involves feeding a continuous strip of metal through a series of rollers, which gradually shape the material into the desired profile. In the case of a capping roll forming machine, the profile produced is typically used as a cover or cap to enclose or finish the edges of various products or structures.

The machine consists of several components, including a material feeding system, a series of forming rollers, cutting mechanisms, and control systems. The material, usually in the form of a coil, is fed into the machine and guided through the rollers, where it undergoes a series of bending and forming operations. The rollers are specifically designed to shape the metal strip into the desired capping profile.

Depending on the requirements, the capping roll forming machine may have additional features such as punching or embossing capabilities to create holes or patterns in the capping profile. The cutting mechanisms can be integrated into the machine to cut the capping profiles to the desired lengths.

Capping roll forming machines offer high efficiency and precision in producing uniform and consistent capping profiles. They are designed for continuous production and can handle various materials such as steel, aluminum, or other metals.

Overall, capping roll forming machines play a crucial role in the manufacturing process by providing a cost-effective and efficient solution for producing capping profiles used in a wide range of applications.

function of ridge capping roll forming machine

The key functions of a ridge capping roll forming machine include:

- Material Feeding: The machine accepts the metal coil or strip and feeds it into the forming stations. The material is typically guided and controlled by rollers and feeding mechanisms.

- Roll Forming: The machine uses a set of rollers and forming stations to gradually shape the metal strip into the desired ridge capping profile. The rollers are designed with the specific contours and dimensions required for the ridge cap design.

- Cutting: The machine may include a cutting mechanism to cut the continuous ridge capping profile into individual sections of the desired length. This ensures the production of standardized ridge caps ready for installation.

- Embossing/Punching: Depending on the design requirements, the machine may have additional stations for embossing or punching holes in the ridge caps. These features can add aesthetic details or facilitate attachment to the roofing system.

- Control System: The machine is equipped with a control system that manages the operation, speed, and synchronization of the rollers and forming stations. It ensures precise and consistent shaping of the metal strip into the ridge capping profile.

What is the purpose of ridge cap tile roll forming machine?

A ridge cap tile roll forming machine is designed to produce ridge cap tiles used in roofing systems. The purpose of this machine is to manufacture ridge cap tiles efficiently and accurately, ensuring consistent quality and precise dimensions.

The ridge cap tiles are an important component of roofing systems, particularly in sloped or pitched roofs. They are installed along the ridges and hips of the roof to provide a protective covering and to prevent water, debris, and other elements from infiltrating the roof structure. Ridge cap tiles also serve an aesthetic purpose by giving the roof a finished and polished appearance.

The ridge cap tile roll forming machine operates by feeding a coil of metal or other suitable material into the machine. The material is then passed through a series of rollers and dies, which shape and form it into the desired ridge cap tile profile. The machine can produce ridge cap tiles in various shapes, sizes, and designs, depending on the specific requirements of the roofing project.

By utilizing a roll forming machine, ridge cap tiles can be produced in a continuous and automated process, significantly improving efficiency and reducing labor costs compared to traditional manual methods of tile fabrication. The machine can also incorporate additional features such as cutting, punching, and embossing functions to create the necessary slots or holes for installation purposes.

Overall, the purpose of a ridge cap tile roll forming machine is to streamline the manufacturing process of ridge cap tiles, ensuring consistent quality, precise dimensions, and increased productivity in roofing projects.

Reviews

There are no reviews yet.