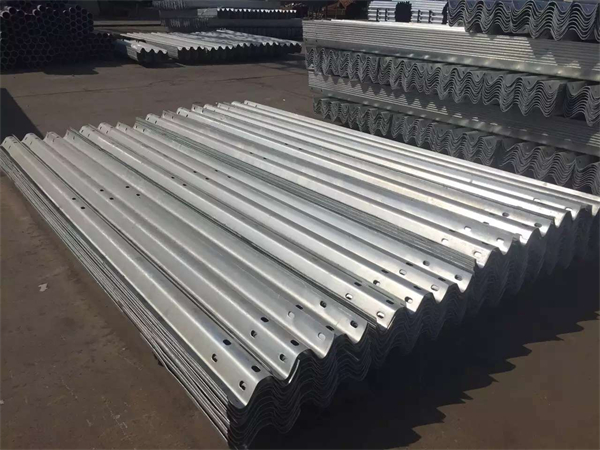

La profileuse pour barrière de sécurité ferroviaire à grande vitesse peut fabriquer des glissières de sécurité à poutre en W, des glissières de sécurité à poutre flexible, des glissières de sécurité à trois vagues et des glissières de sécurité à poutre en caisson. Elle peut également être conçue comme des profils à deux vagues ou à trois vagues dans une seule machine, il vous suffit d'ajouter quelques stations de formage à l'extrémité de la machine conformément à notre dessin. L'épaisseur de la glissière de sécurité est généralement de 2.0mm-4mm, le matériau de l'acier est Q235.

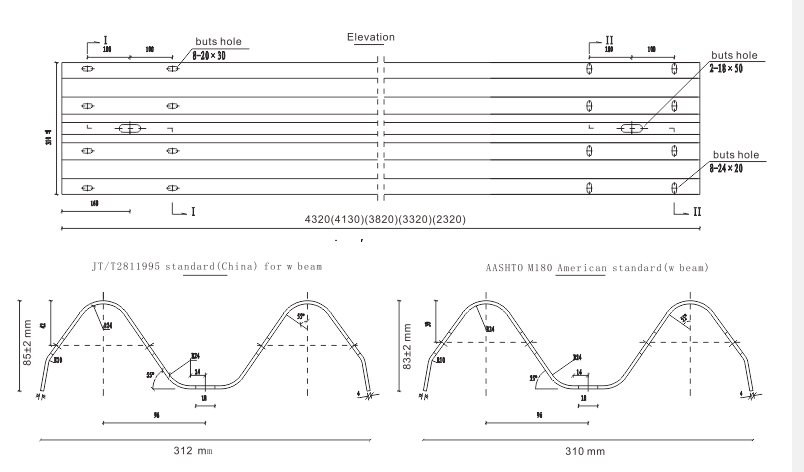

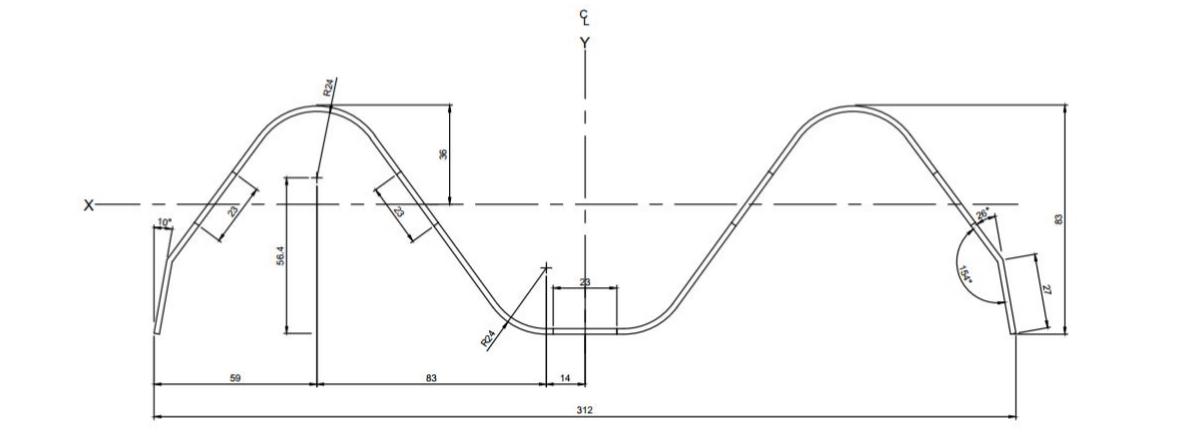

Dessin du profil de la machine à former les barrières de sécurité pour les trains à grande vitesse

Profil de glissière de sécurité de la machine de formage de glissières de sécurité pour chemin de fer à grande vitesse

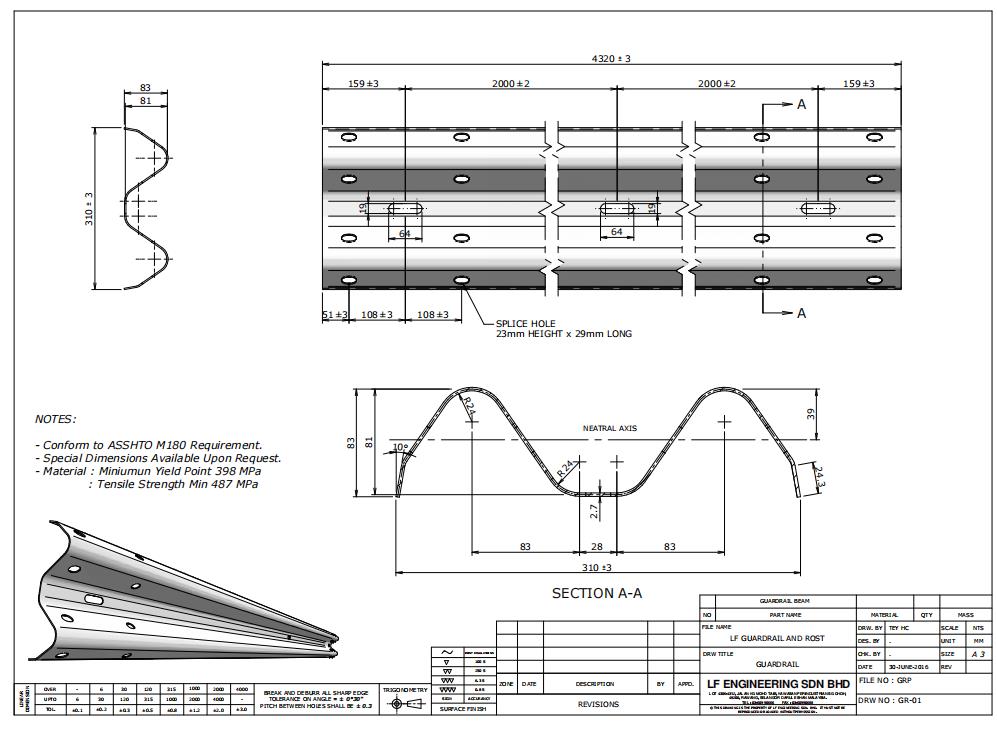

Échantillon déjà réalisé

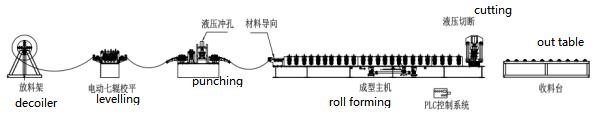

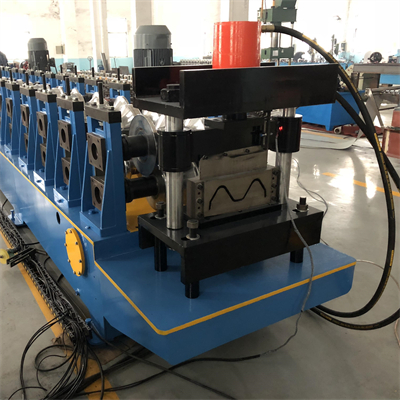

Le flux de production des équipements

Déboîtage, mise à niveau, poinçonnage de la tôle, profilage, coupe hydraulique à la longueur, table de sortie.

|

Liste des machines

|

Dérouleur hydraulique de 5 tonnes | 1 jeu |

| Machine de formage de rouleaux principal | 1 jeu | |

| Machine d'alimentation et de nivellement | 1 jeu | |

| Poinçonneuse hydraulique | 1 jeu | |

| Dispositif de coupe hydraulique | 1 jeu | |

| Moules de poinçonnage | 2 ensembles | |

| Boîtier de commande | 1 unité | |

| Hors table | 2 unités | |

| Station hydraulique | 1 unité |

La structure de l'équipement

1. Dérouleur hydraulique 5T

- Machine à dérouler simple, un côté peut mettre du matériel

- Adopte un système hydraulique automatique

- Poids de la bobine (Max):5000kg

- Diamètre intérieur : 460-520 mm

- Diamètre de la bobine (Max) : 1300mm

- Cylindre à huile dia:1200mm pression de travail : 10mpa

- Largeur de bobine (max.):500mm

- Vitesse de travail : environ 0-25m/min

- Puissance : 4KW

2. Mise à niveau

Principales caractéristiques de la machine :

Les propriétés mécaniques du rouleau niveleur, telles que la rigidité et la concentration de la rugosité de la surface, augmentent considérablement après la trempe et le revenu. Il comprend un rouleau de pincement et un rouleau de nivellement. Le rouleau de pincement peut s'ajuster le long du rouleau. Le rouleau de nivellement utilise l'ensemble de la structure. Il y a deux points de réglage à l'avant et à l'extrémité. Il peut former un certain angle incliné pour améliorer la qualité du planage. L'orifice d'alimentation de la machine à planer est équipé d'une paire de rouleaux de guidage lisses et de deux paires de rouleaux de guidage verticaux. Le rouleau vertical de guidage peut se déplacer au centre ou en même temps. Il est réglé à l'aide d'un volant, ce qui facilite le centrage.

- Introduire la feuille dans le rouleau de guidage (il est réglable à droite et à gauche).

- Rouleau d'alimentation : diamètre de ¢160mm ; matériau : acier 40CR, HRC48-52.

- Rouleau niveleur : 3 rouleaux en haut, 4 stations en bas(total 7 stations), matériau : acier 40CR, HRC48-52.

- Diamètre du rouleau niveleur : 180 mm

3. Poinçonnage hydrulique

- Utilisation du poinçonnage hydraulique

- Cylindre à huile dia : ¢180mm

- Pression de travail : 30mpa

- Matériau du moule : Cr12 trempé 58°-62°

- Puissance hydraulique : 7,5 kw

- Taille : 1,5m de long*1,1m de large*1,2m de haut

4. Machine de formage de rouleaux de barrière de sécurité ferroviaire à grande vitesse

- Puissance moteur principal : 22kw

- Station : adopter la fonte HT50

- Moteur de décélération : fabriqué à Shanghai ou à Changzhou

- Entraînement : Entraînement par boîte de vitesses

- Arbre principal dia:¢120mm, matériel : 45﹟ acier forgé

- Matériau des rouleaux : GCR15 trempé 58°-62°, chromé

- Station de roulement : environ 15 stations

- Épaisseur du matériau : 2,5-4,0 mm

- Vitesse de la machine : environ 3-5m/min

- Alimentation électrique : 380V 50HZ, 3 phases

- Système de contrôle : PLC avec écran tactile

5. Coupe hydraulique

- Coupe hydraulique

- Matériau du couteau : Cr12Mov, trempé 58°-62°.

- Cylindre à huile dia:250mm

- Pression de travail : 60mpa

- Trajet de travail : 80mm

6. Boîtier de commande

- L'ensemble de la ligne est contrôlé par un système de commande PLC, avec un écran tactile pour assurer l'interactivité entre l'homme et le PLC.

- Type de fonctionnement : manuel/auto à deux types d'interrupteurs. En position manuelle : peut faire fonctionner chaque partie de la machine.

- Alimentation : 380V, 50 Hz, 3Phase (ajusté à la demande)

- Mesure automatique de la longueur et de la quantité ;

- Longueur et quantité contrôlées par PLC

- L'imprécision de longueur peut être corrigée facilement.

- Panneau de commande : interrupteur à bouton et écran tactile

- Unité de longueur : millimètre (activé sur le panneau de commande)

Avis

Il n’y a pas encore d’avis.