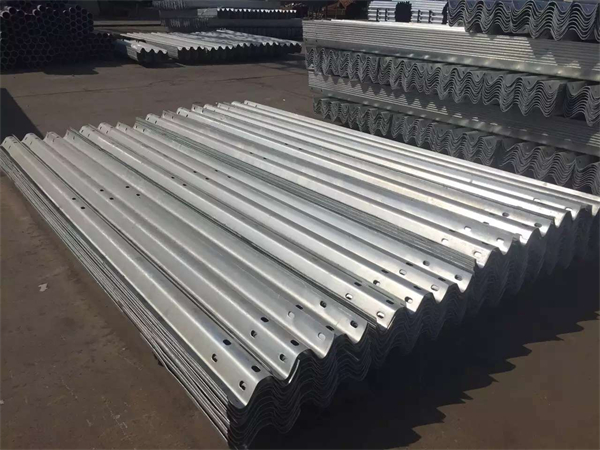

High speed Guard Railway Crash barrier roll forming machine can make W beam guardrail, flex-beam guardrail, three wave guardrail and Box Beam Guardrail, also can be designed as two waves or three waves profiles in one machine, you just need to add some forming stations at the end of the machine according to our drawing. The guardrail’s thickness is usually 2.0mm-4mm, steel material is Q235.

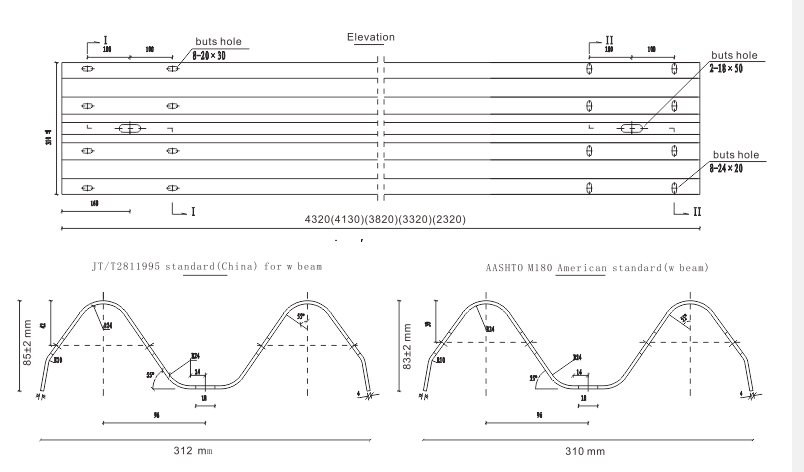

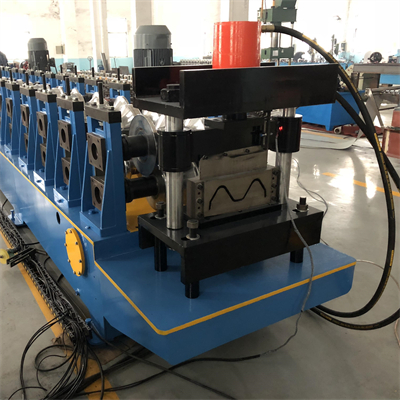

Profile Drawing of High speed Guard Railway Crash barrier roll forming machine

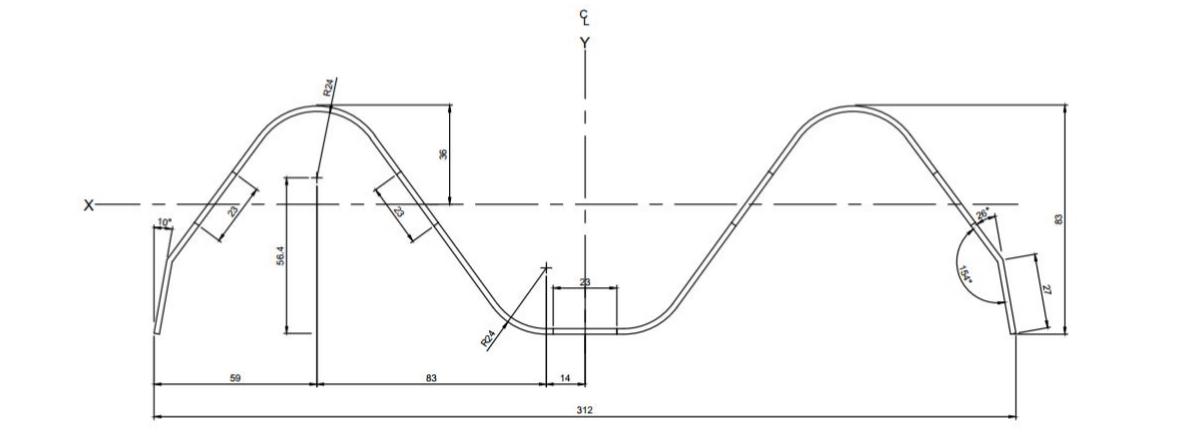

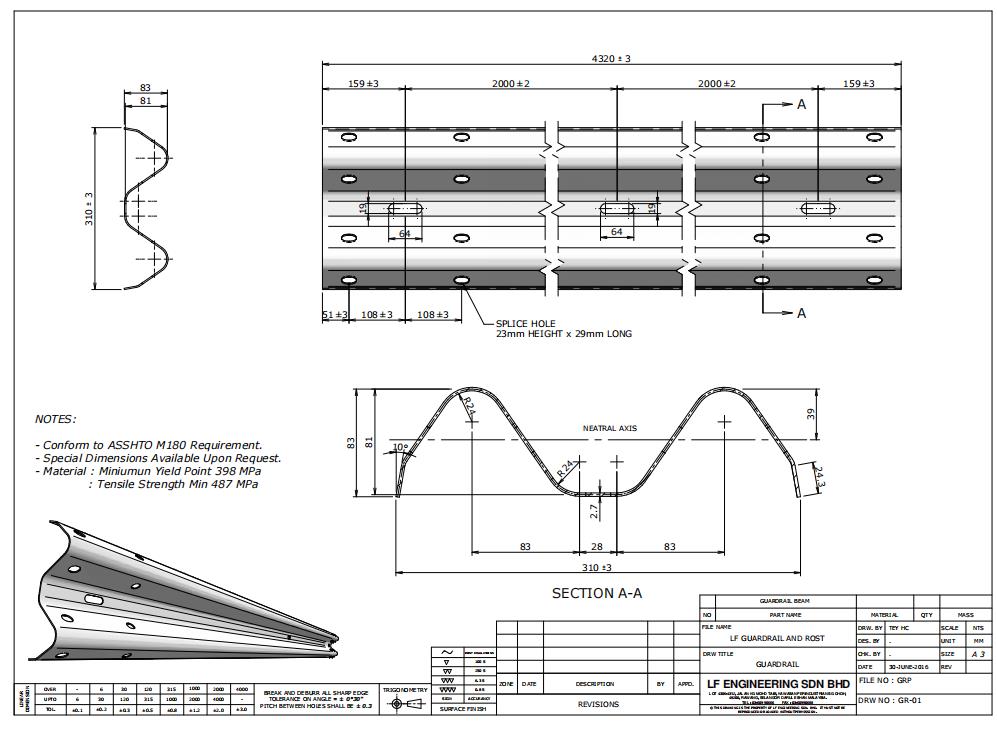

The guardrail profile of High speed Guard Railway Crash barrier roll forming machine

Sample we made before

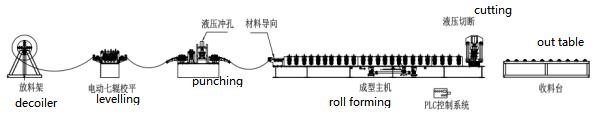

The production flow of equipment

Decoiling—leveling—-Punching of the sheet —— roll forming–hydraulic cut to length–out table

|

Machine list

|

5 tons hydraulic Un-coiler | 1 set |

| Main roll forming machine | 1 set | |

| Feeding and leveling machine | 1 set | |

| Hydraulic punching machine | 1 set | |

| Hydraulic cutting device | 1set | |

| Punching moulds | 2 sets | |

| Control box | 1 unit | |

| Out table | 2 units | |

| Hydraulic station | 1 unit |

The structure of equipment

1. 5T Hydraulic de-coiler

- Single unrolling machine, one side can put material

- Adopt automatic hydraulic system

- Coil weight (Max):5000kg

- Inner diameter:460-520mm

- Coil dia (Max):1300mm

- Oil cylinder dia:1200mm working pressure: 10mpa

- Coil Width (Max.):500mm

- Working speed: about 0-25m/min

- Power: 4KW

2. Leveling

Main features of the machine:

The leveling roller’s mechanical property such as rigidity and roughness concentration of the surface are rising very much after hardening and tempering. It includes pinch roll and leveling roll. The pinch roll can adjust along. The leveling roll uses the whole structure. There are two adjusting point at the front and the end. It can form a certain banked angle to improve the leveling quality. The feeding port of the leveling machine has a pair of guide plain-barrelled roll and two pairs of guide vertical roll. The guide vertical roll can moves centered or moves at the same time. It is adjusted by hand wheel, so it is convenient to centered.

- Feeding the sheet to the guide roller (it is adjustable by right and left).

- Feeding roller: diameter is ¢160mm; material is 40CR steel, HRC48-52.

- Leveling roller: upper is 3 rollers, down is 4 stations(total is 7 stations), material is 40CR steel, HRC48-52.

- Diameter of leveling roller: 180mm

3. Hydrulic Punching

- Using hydraulic punching

- Oil cylinder dia: ¢180mm

- Working pressure:30mpa

- Mould material: Cr12 quenched 58°-62°

- Hydraulic power:7.5kw

- Size: 1.5m long*1.1m wide*1.2m high

4. High speed Guard Railway Crash barrier roll forming machine

- Main motor power: 22kw

- Station: adopt cast iron HT50

- Decelerating motor: made in Shanghai or Changzhou

- Drive: Gear box driving

- Main shaft dia:¢120mm, material: 45﹟forge steel

- Roller material: GCR15 quenched 58°-62°,chromed

- Roll station: about 15 stations

- Material thickness: 2.5-4.0mm

- Machine speed: about 3-5m/min

- Power supply: 380V 50HZ, 3 phases

- Control system: PLC with touch screen

5. Hydraulic cutting

- Hydraulic cutting

- Knife material: Cr12Mov,quenched 58°-62°

- Oil cylinder dia:250mm

- Working pressure:60mpa

- Working journey: 80mm

6. Control box

- Full line is controlled by PLC control system, touch screen operation to achieve the human and PLC interactive.

- Operation type: manual /auto two type switch. In manual position: can run the each part of the machine.

- Power supplier: 380V, 50 Hz, 3Phase (adjusted with the requestment)

- Length & quantity measurement automatically;

- Length & quantity controlled by PLC

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- Unit of length: millimeter (switched on the control panel)

Reviews

There are no reviews yet.