Spesifikasi

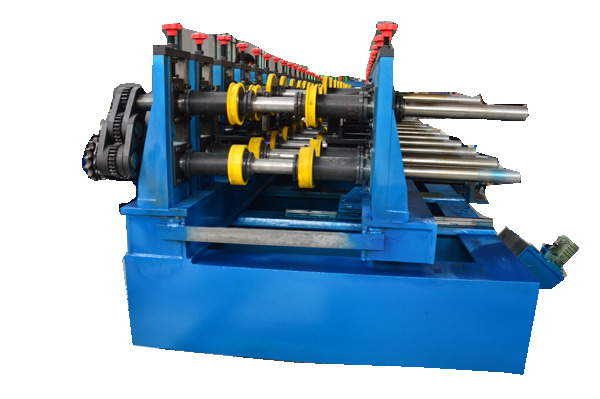

- Ketebalan: 1.0-2.0mm

- Bahan baku: Baja galvanis dan lembaran baja hitam

- Lebar bahan: 100-600mm, tinggi: 100-200mm

- Kecepatan Kerja: 12 meter / mnt

- Langkah-langkah Pembentukan: 20 stasiun

- Bahan Roller: Gcr15, Quench HRC58-62 Berlapis Chrome

- Bahan Poros: 45# Advanced Steel (Diameter: 90mm), pemurnian termal

- Sistem yang digerakkan: Penggerak gearbox, diameter poros 100mm

- Daya Utama dengan peredam: 22KW WH Terkenal Cina

- Pemotongan: Pemotongan Hidrolik Cr12mov

- Bahan Pisau Pemotong: Cr12Mov, Quench HRC58-62

- Daya Stasiun Hidrolik: 7.5KW Wuxi Wanshen Merek Cina Terkenal

- Seluruh mesin dikendalikan oleh komputer industri-PLC.

- PLC-Panasonic, Jepang

- Layar Sentuh-Beijing Kunlun Encoder-Omron, Jepang

- Bagian listrik–Schneider

- Sesuaikan ketinggian dengan motor dan rel, yang dikendalikan oleh PLC.

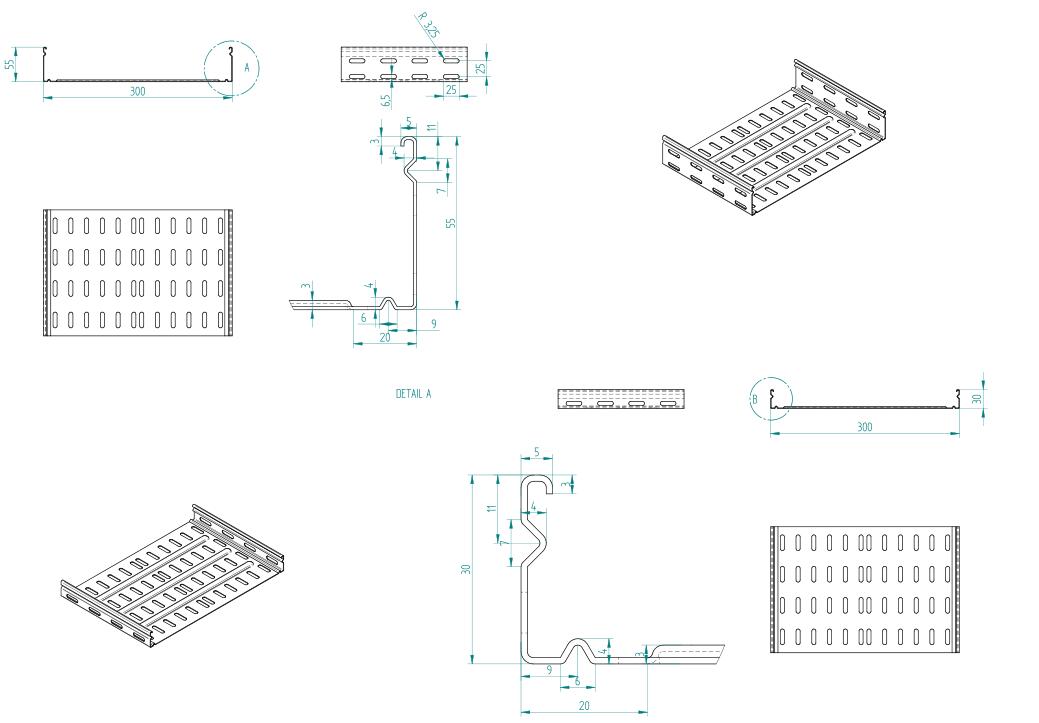

Gambar profil untuk opsi

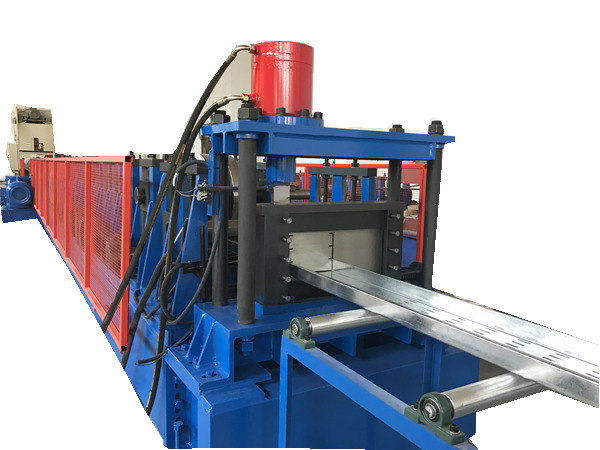

Daftar mesin

| Nama | Kuantitas |

| Decoiler hidraulik 5 ton | 1 set |

| Perata rol | 1 set |

| Layanan pemberian makan servo | 1 set |

| Mesin press pelubang | 1 set |

| Mesin pembentuk gulungan | 1 set |

| sistem PLC | 1 set |

| Perangkat pemotong | 1 set |

| Tabel keluar | 2 set |

| Suku cadang | 1 set |

Apa itu mesin pembentuk baki kabel?

Mesin pembuat baki kabel adalah jenis mesin industri yang digunakan untuk membuat baki kabel. Baki kabel adalah sistem pendukung yang digunakan dalam industri konstruksi dan kelistrikan untuk menahan dan mengatur kabel dan kabel listrik. Mereka menyediakan cara yang aman dan efisien untuk merutekan dan melindungi kabel di bangunan komersial dan industri.

Mesin pembentuk baki kabel dirancang untuk mengotomatiskan proses pembuatan baki kabel. Mesin ini biasanya terdiri dari serangkaian rol, cetakan, dan komponen lain yang membentuk dan membentuk lembaran logam menjadi profil baki kabel yang diinginkan. Mesin ini dapat menangani berbagai jenis logam, seperti baja atau aluminium, tergantung pada kebutuhan spesifiknya.

Pengoperasian mesin pembentuk baki kabel melibatkan pengumpanan lembaran logam ke dalam mesin, di mana lembaran logam tersebut kemudian dilewatkan melalui rol yang membengkokkan dan membentuknya ke dalam konfigurasi baki yang diinginkan. Mesin ini juga dapat melakukan tugas-tugas lain, seperti melubangi lubang atau slot di baki untuk titik masuk dan keluar kabel.

Dengan menggunakan mesin pembuat baki kabel, produsen dapat mencapai presisi dan efisiensi tinggi dalam memproduksi baki kabel. Kemampuan otomatisasi mesin ini membantu merampingkan proses produksi, mengurangi biaya tenaga kerja, dan memastikan kualitas yang konsisten pada baki kabel yang diproduksi.

Berapa harga mesin pembuat gulungan baki kabel?

Harga mesin pembuat gulungan baki kabel dapat bervariasi tergantung pada beberapa faktor, termasuk spesifikasi mesin, fitur, dan produsen atau pemasok. Selain itu, kondisi pasar, lokasi geografis, dan fluktuasi mata uang juga dapat memengaruhi harga. Oleh karena itu, sulit untuk memberikan harga yang tepat tanpa detail yang spesifik.

Umumnya, mesin pembuat gulungan baki kabel dapat berkisar dari beberapa ribu dolar hingga beberapa ratus ribu dolar. Model dasar dengan fitur standar dan kapasitas produksi yang lebih rendah cenderung lebih murah, sementara mesin dengan fitur canggih, kecepatan produksi yang lebih tinggi, dan kemampuan ukuran baki yang lebih besar bisa lebih mahal.

Disarankan untuk menghubungi produsen, pemasok, atau distributor mesin roll forming untuk baki kabel untuk mendapatkan informasi harga yang akurat. Mereka dapat memberi Anda penawaran harga terperinci berdasarkan kebutuhan spesifik dan opsi penyesuaian Anda. Selain itu, disarankan untuk membandingkan harga dari berbagai sumber untuk memastikan Anda mendapatkan nilai terbaik untuk investasi Anda.

5 pabrik mesin pembentuk gulungan baki kabel teratas di Cina

- Sussman Machinery (Wuxi) Co, Ltd mengkhususkan diri dalam pembuatan mesin roll membentuk baja bentuk dingin sekitar 20 tahun, mengekspor garis menggorok dan seluruh kelompok bisnis perdagangan internasional.

- Shanghai Believe Industry Co, Ltd: Shanghai Believe Industry mengkhususkan diri dalam produksi mesin roll forming untuk berbagai industri, termasuk mesin roll forming baki kabel. Mereka memiliki reputasi yang kuat dalam memberikan mesin yang andal dan berkualitas tinggi.

- Jiangsu Huazhong Roll Forming Machine Co, Ltd: Jiangsu Huazhong adalah produsen terkemuka mesin roll forming di Cina. Mereka menawarkan beragam jenis mesin, termasuk mesin pembuat gulungan baki kabel, yang dikenal karena presisi dan efisiensinya.

- Cangzhou Zhongtuo International Trade Co, Ltd: Cangzhou Zhongtuo dikenal karena keahliannya dalam mesin roll forming, termasuk mesin roll forming baki kabel. Mereka menyediakan rangkaian lengkap mesin yang dirancang untuk memenuhi berbagai persyaratan produksi.

- Botou Kexinda Roll Forming Machine Co, Ltd: Botou Kexinda mengkhususkan diri dalam produksi mesin roll forming untuk berbagai aplikasi, termasuk mesin roll forming baki kabel. Mereka memiliki eksistensi yang kuat di industri ini dan dikenal dengan mesin yang tahan lama dan berkinerja tinggi.

Ulasan

Belum ada ulasan.