Specification

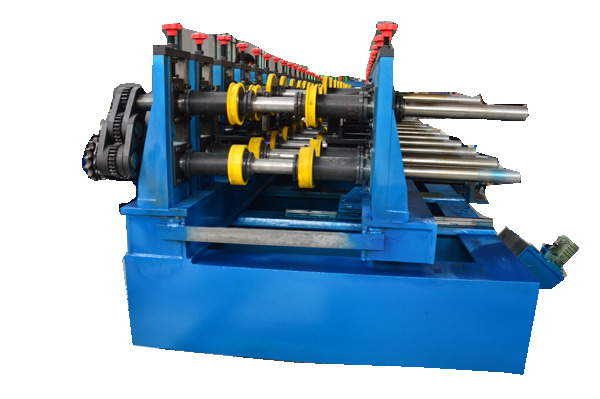

- Thickness:1.0-2.0mm

- Raw material: Galvanized steel and black steel sheets

- Material width:100-600mm, height:100-200mm

- Working Speed: 12 meters / min

- Forming Steps: 20 stations

- Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

- Material of Shaft: 45# Advanced Steel (Diameter: 90mm), thermal refining

- Driven system: Gearbox drive, shafts diameter 100mm

- Main Power with reducer: 22KW WH Chinese Famous

- Cutting: Hydraulic Cutting Cr12mov

- Material of Cutting Knife: Cr12Mov, Quench HRC58-62

- Hydraulic Station Power: 7.5KW Wuxi Wanshen Famous Chinese Brand

- The whole machine is controlled by industry computer-PLC.

- PLC–Panasonic, Japan

- Touch Screen—Beijing Kunlun Encoder–Omron, Japan

- Electric parts–Schneider

- Adjust the height by the motors and the rails, controlled by the PLC.

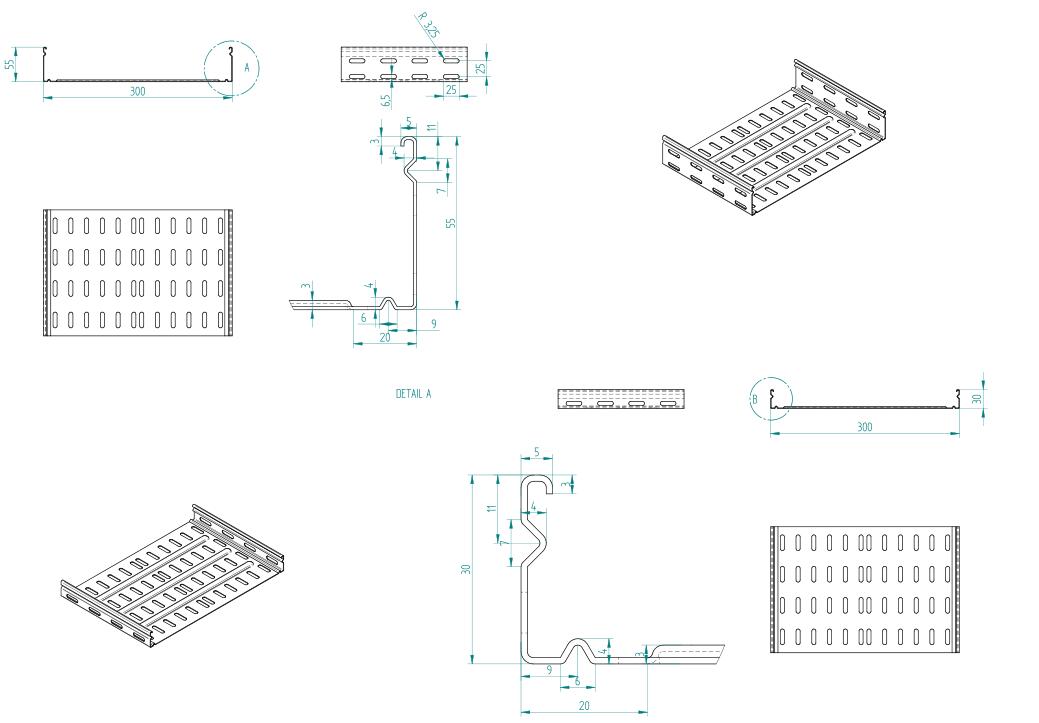

Profile drawings for option

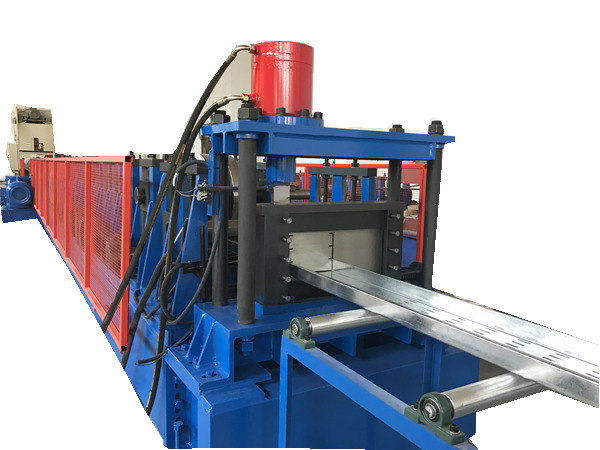

Machine list

| Name | Quantity |

| 5 tonshydraulic decoiler | 1 set |

| Roller leveller | 1 set |

| Servo feeding service | 1 set |

| Punching press machine | 1 set |

| Roll forming machine | 1 set |

| PLC system | 1 set |

| Cutting device | 1 set |

| Out tables | 2 set |

| Spare parts | 1 set |

What is cable tray forming machine?

A cable tray forming machine is a type of industrial machinery used to manufacture cable trays. Cable trays are support systems used in the construction and electrical industries to hold and organize electrical cables and wires. They provide a safe and efficient way to route and protect cables in commercial and industrial buildings.

The cable tray forming machine is designed to automate the process of manufacturing cable trays. It typically consists of a series of rollers, dies, and other components that shape and form metal sheets into the desired cable tray profiles. The machine can handle various types of metal, such as steel or aluminum, depending on the specific requirements.

The operation of a cable tray forming machine involves feeding metal sheets into the machine, where they are then passed through rollers that bend and shape them into the desired tray configuration. The machine can also perform other tasks, such as punching holes or slots in the trays for cable entry and exit points.

By using a cable tray forming machine, manufacturers can achieve high precision and efficiency in producing cable trays. The machine’s automation capabilities help streamline the manufacturing process, reduce labor costs, and ensure consistent quality in the produced cable trays.

How much does cable tray roll forming machine price?

The price of a cable tray roll forming machine can vary depending on several factors, including the machine’s specifications, features, and the manufacturer or supplier. Additionally, market conditions, geographical location, and currency fluctuations can also influence the pricing. Therefore, it is challenging to provide an exact price without specific details.

Generally, cable tray roll forming machines can range in price from a few thousand dollars to several hundred thousand dollars. Basic models with standard features and lower production capacities tend to be less expensive, while machines with advanced features, higher production speeds, and larger tray size capabilities can be more costly.

It is recommended to reach out to manufacturers, suppliers, or distributors of roll forming machines for cable trays to obtain accurate pricing information. They can provide you with detailed quotations based on your specific requirements and customization options. Additionally, it’s advisable to compare prices from multiple sources to ensure you get the best value for your investment.

top 5 cable tray roll forming machine factory in China

- Sussman Machinery(Wuxi)Co., Ltd. is specialized in manufacturing shape steel cold roll forming machines about 20 years, exporting slitting line and whole group international trade business.

- Shanghai Believe Industry Co., Ltd.: Shanghai Believe Industry specializes in the production of roll forming machines for different industries, including cable tray roll forming machines. They have a strong reputation for delivering reliable and high-quality machines.

- Jiangsu Huazhong Roll Forming Machine Co., Ltd.: Jiangsu Huazhong is a leading manufacturer of roll forming machines in China. They offer a diverse range of machinery, including cable tray roll forming machines, known for their precision and efficiency.

- Cangzhou Zhongtuo International Trade Co., Ltd.: Cangzhou Zhongtuo is known for its expertise in roll forming machinery, including cable tray roll forming machines. They provide a comprehensive range of machines designed to meet various production requirements.

- Botou Kexinda Roll Forming Machine Co., Ltd.: Botou Kexinda specializes in the production of roll forming machines for different applications, including cable tray roll forming machines. They have a strong presence in the industry and are known for their durable and high-performance machines.

Reviews

There are no reviews yet.