Mesin roll forming panel dinding atap untuk dekoratif dapat menghasilkan kisaran ketebalan material 0,3-0,8mm, bahan PPGI, baja galvalum dan baja galvanis, juga kami dapat menyesuaikan mesin sesuai dengan gambar Anda, khususnya pitch dan tinggi setiap gelombang, untuk kecepatan mesin, kami dapat melakukan kecepatan normal 8-12m / mnt.

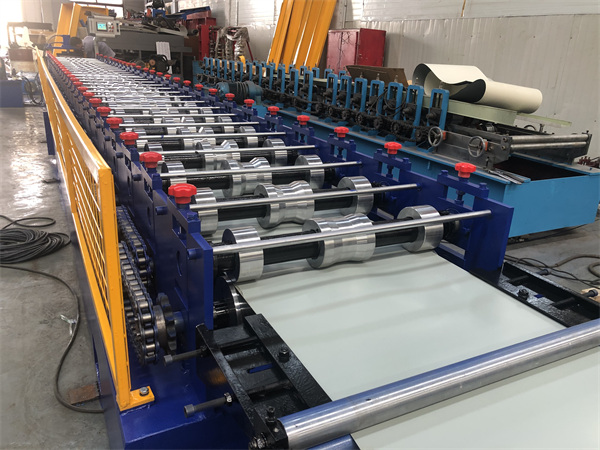

Mesin roll forming panel dinding atap untuk desain dekoratif adalah unit satu, yang berarti kotak kontrol dan motor semuanya diletakkan di bawah rangka mesin, ketika Anda mendapatkan mesin, tidak perlu merakit dan menghubungkan kabel mesin yang rumit, Anda hanya perlu menghubungkan satu kabel utama, kemudian mesin bekerja. Ini menghemat lebih banyak waktu dan ruang.

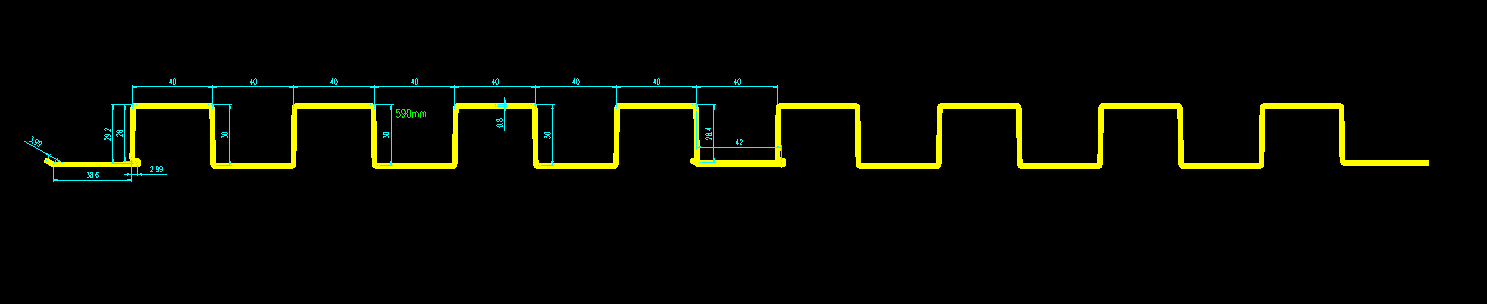

Gambar Profil Mesin pembuat gulungan panel Dinding Atap untuk dekoratif

Proses Teknologi Mesin Roll Forming Panel Dinding Atap untuk dekoratif

Membuka gulungan-Mengumpankan dengan pemandu-Pra-pemotongan-Pembentukan gulungan-Pemotongan-Pengumpulan produk

|

Daftar mesin

|

5 ton de-coiler pasif | 1 set |

| Perangkat pra-pemotongan | 1 set | |

| Mesin pembentuk gulungan utama | 1 set | |

| Kotak Kontrol PLC | 1 unit | |

| Alat pemotong hidrolik | 1 unit | |

| Meja 4 meter | 1 unit | |

| Penutup pengaman | 1 set |

Data Teknis mesin pembuat gulungan panel Dinding Atap untuk dekoratif

1. 5 Ton Un-coiler Hidraulik

- Diameter bagian dalam koil: ¢460-520mm

- Diameter maksimum koil: ¢1300mm

- Lebar Kumparan Maks: 1250mm

2. Perangkat Pra-pemotongan

3. Mesin Roll Forming

- Kecepatan Bergulir: Sekitar 10-12m / mnt

- Ketebalan lembaran baja: 3 mm hingga 0.8mm PPGI, Baja Galvanis

- Stasiun Rol: sekitar 24 stasiun

- Bahan Rol : Baja tempa 45#, dilapisi dengan krom

- Bahan Poros dan DIA: ¢76mm, bahannya adalah baja tempa 45#, Chrome dengan pendinginan

- Daya Motor Utama: 5kw

- Tekanan Hidraulik: 12Mpa

- Pemasok daya: 380V, 50HZ, 3 fase atau disesuaikan dengan kebutuhan pelanggan

- Cara Berkendara: bychain

- Warna Mesin: biru atau disesuaikan

- Ukuran mesin pembentuk: Sekitar 10500 * 1000 * 1200mm

- Berat mesin: sekitar 10 ton

- Sistem kontrol: Panel kontrol PLC dengan layar sentuh

Desain mesin kami adalah unit satu, yang berarti kotak kontrol dan motor semuanya diletakkan di bawah rangka mesin, ketika Anda mendapatkan mesin, tidak perlu merakit dan menghubungkan kabel mesin yang rumit, maka mesin akan bekerja. Ini menghemat lebih banyak waktu dan ruang.

4. Pemotongan hidrolik

(1) Gerakan pemotongan: Mesin utama berhenti dan kemudian memotong secara otomatis. Setelah memotong, mesin utama akan hidup kembali secara otomatis.

(2) Bahan pisau: CR12Mov dengan perlakuan panas

(3) Pengukuran panjang: Secara otomatis

(4) Ketebalan pemotongan: 0,3 - 0,8mm

(5) Daya Stasiun Hidraulik: 4 KW

5. Tabel Keluar

Ini mengadopsi baja yang dilas dan roller yang didukung untuk mengirimkan produk.

Size:4000*1350*1200mm

6. Kotak Kontrol

(1) Pemasok daya: 380V, 50 Hz, 3Fase (disesuaikan dengan permintaan)

(2) Pengukuran panjang & kuantitas secara otomatis;

(3) Panjang & kuantitas dikontrol oleh PLC

(4) Ketidaktepatan panjang dapat diubah dengan mudah.

(5) Panel kontrol: Sakelar tipe tombol dan layar sentuh

(6) Satuan panjang: milimeter (diaktifkan pada panel kontrol)

Suku Cadang

| Nama | Nomor | |

|

Peralatan

|

Alat pengukur rasa | 1 |

| Kunci pas ukuran | 1 | |

| Kunci pas segi enam bagian dalam | 1 | |

| Penjepit | 1 | |

| Kunci pas standar | 1 | |

| Menggeser kunci pas | 1 | |

| Obeng berlubang | 1 | |

|

Aksesori lainnya

|

Rantai | 2 buah |

| Bantalan (Haerbin) | 2 buah |

Apa itu mesin roll forming panel atap dan dinding?

Mesin roll forming panel atap dan dinding adalah mesin industri khusus yang digunakan dalam industri konstruksi untuk membuat panel atap dan dinding logam. Mesin ini dirancang untuk mengotomatiskan proses pembentukan lembaran logam kontinu menjadi profil dan bentuk tertentu yang diperlukan untuk aplikasi pelapis atap dan dinding.

Mesin roll forming biasanya terdiri dari serangkaian roller dies, yang secara progresif membengkokkan dan membentuk lembaran logam saat melewati mesin. Mesin ini dilengkapi dengan berbagai komponen, seperti decoiler untuk menahan gulungan logam, unit leveling untuk meluruskan lembaran, unit pelubang untuk membuat lubang atau slot, dan unit pemotong untuk memotong panel sesuai panjang yang diinginkan.

Pengoperasian mesin melibatkan pengumpanan kumparan logam ke dalam mesin, di mana kumparan logam tersebut dilepaskan dan dipandu melalui rol. Rol secara bertahap membentuk lembaran logam ke dalam profil yang diinginkan, yang dapat bervariasi berdasarkan persyaratan spesifik proyek. Panel yang sudah jadi kemudian dipotong sesuai panjang yang diinginkan dan ditumpuk atau dikumpulkan untuk diproses atau diangkut lebih lanjut.

Mesin roll forming panel atap dan dinding menawarkan beberapa keunggulan dalam industri konstruksi. Mesin ini memberikan efisiensi produksi yang tinggi, akurasi, dan konsistensi dalam membentuk panel logam. Mesin ini dapat menghasilkan panel dengan panjang dan profil yang berbeda, memungkinkan penyesuaian sesuai dengan spesifikasi proyek. Mesin ini biasanya digunakan dalam pembuatan atap logam, pelapis dinding, dan aplikasi arsitektur lainnya yang membutuhkan panel yang tahan lama dan estetis.

Secara keseluruhan, mesin roll forming panel atap dan dinding merupakan peralatan vital dalam industri konstruksi, memungkinkan produksi panel logam yang efisien yang digunakan dalam berbagai proyek bangunan.

aplikasi mesin pembuat gulungan panel dinding atap

Aplikasi mesin roll forming panel atap dan dinding terutama di industri konstruksi, di mana mesin ini memainkan peran penting dalam pembuatan panel logam untuk atap dan pelapis dinding. Berikut adalah beberapa aplikasi spesifik dari mesin-mesin ini:

- Atap Perumahan dan Komersial: Mesin roll forming panel atap digunakan untuk memproduksi panel logam yang biasa digunakan dalam aplikasi atap perumahan dan komersial. Mesin ini dapat membuat berbagai profil, seperti bergelombang, jahitan berdiri, dan trapesium, yang menawarkan daya tahan, ketahanan terhadap cuaca, dan daya tarik estetika.

- Bangunan Industri: Panel logam yang diproduksi dengan mesin roll forming banyak digunakan untuk pelapis dinding pada bangunan industri, gudang, pabrik, dan struktur serupa lainnya. Panel-panel ini memberikan perlindungan terhadap elemen cuaca, meningkatkan insulasi, dan menawarkan tampilan yang ramping pada eksterior bangunan.

- Bangunan Pertanian: Panel logam berbentuk gulungan juga digunakan pada bangunan pertanian, seperti lumbung, gudang, dan fasilitas penyimpanan. Panel-panel ini memberikan kekuatan, daya tahan, dan ketahanan terhadap korosi, sehingga cocok untuk struktur pertanian.

- Struktur Komersial dan Ritel: Keserbagunaan mesin roll forming panel atap dan dinding memungkinkan produksi panel khusus yang digunakan pada bangunan komersial dan ritel. Panel-panel ini dapat disesuaikan untuk memenuhi persyaratan arsitektur dan estetika desain tertentu, memberikan solusi yang menarik secara visual dan tahan lama.

- Proyek Infrastruktur: Panel logam yang diproduksi oleh mesin roll forming digunakan dalam proyek infrastruktur, termasuk pusat transportasi, stadion, bandara, dan konstruksi berskala besar lainnya. Panel-panel ini menawarkan integritas struktural, perlindungan terhadap cuaca, dan berkontribusi terhadap estetika keseluruhan proyek.

- Proyek Perumahan: Selain untuk aplikasi komersial, panel atap dan dinding yang diproduksi oleh mesin roll forming juga digunakan dalam proyek perumahan. Mereka digunakan untuk atap, dinding, dan aplikasi eksterior lainnya, menawarkan daya tahan, efisiensi energi, dan berbagai pilihan desain.

Secara keseluruhan, mesin roll forming panel atap dan dinding memiliki aplikasi yang luas dalam industri konstruksi, menyediakan panel logam yang hemat biaya, efisien, dan berkualitas tinggi untuk berbagai jenis bangunan dan struktur.

Ulasan

Belum ada ulasan.