Roll forming is a manufacturing process used to shape metal coils into customized profiles with long lengths. Roll forming machines are an efficient and cost-effective way to produce metal roofing panels, wall panels, door skins, structural framing members, and many other building products.

A roof roll forming machine is specifically designed to produce metal roofing panels from coil stock. Roof panels come in many shapes and styles, like ribbed or corrugated profiles, to provide structure, strength, and aesthetic appeal to a metal roof. Roll formed roof panels offer many benefits compared to other roofing materials.

How Roll Forming Works

Roll forming works by gradually shaping metal coil through a series of rolling stations. Each station incrementally forms the metal into the desired profile through a series of roller dies. The roller dies only contact the metal along a narrow band, which allows the roll forming process to avoid scraping or marking the surface of the metal.

First, the coil sheet enters a de-coiling machine to align the sheet and feed it into the roll former. Next, the sheet passes through a straightening mechanism to remove coil set and correct any warp or bow in the material.

After initial prep, the sheet enters the roll forming stations. At each station, contoured rollers make small bends until the full profile is formed. Stations can perform operations like flattening, curving, bending, and twisting the metal into complex shapes. Rollers can include:

- Breakdown rollers – Begin shaping the profile with initial forming

- Finishing rollers – Complete the forming with final shaping details

- Cut-off rollers – Cut profile to length after roll forming

The key advantage of roll forming is its continuous, efficient, and adaptable process. Roll formers produce lengths of finished metal products rapidly once initially set up. Operators can rapidly change roller dies to switch profiles and meet shifting production demands.

Components of a Roof Roll Forming Machine

Roof roll forming lines contain a sequential arrangement of functional components that unwind, prep, shape, and cut the metal coils into roof panels. Key components include:

De-Coiler

The de-coiler hold the large coil of sheet metal and properly unwinds it to feed into the roll former. De-coilers provide adjustable tension control to manage coil unwinding.

Sheet Guide

Sheet guides keep the coil sheet straight and centered to properly enter the roll forming stations.

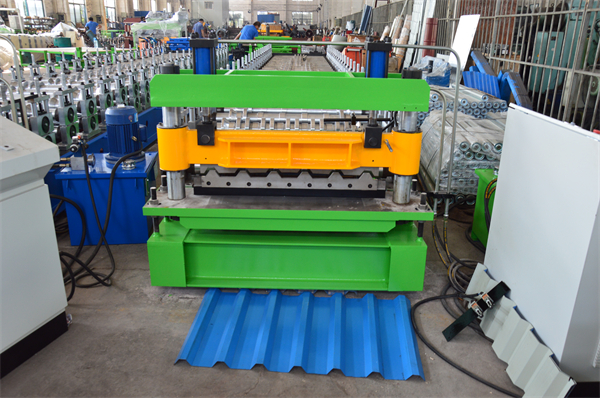

Roll Forming Stations

The roll forming stations shape the metal incrementally as it passes through the sequential stations. Stations apply pressure using hardend rollers to make small bends in the material without marring the surface.

Hydraulic System

Hydraulic cylinders apply pressure and force to the roller dies for precision forming. The hydraulic system allows manipulation of the rollers for quick die changeover and profile adjustments.

Cut-Off System

The cut-off system severs the finished roof panel profiles at a preset length for individual sheet output. Cut-off options include rotating shears or saws.

Runout Tables

Runout tables collect the cut panels and provide space for inspecting and sorting finished pieces. They allow the panels to move smoothly out of the roll former.

Control System

The controls monitor line speed, roller pressure, feed index, and other parameters to synchronize the roll forming process for consistent output.

Types of Roof Panel Profiles

Roll forming machines produce roof panels in many different cross-sectional shapes. Common roof panel profiles include:

- Standing Seam – Flat pan with an upward facing seam. Provides a slim stacked joint look.

- Ribbed – Deep angular ribs run vertically. Provides strength and spanning capability.

- Corrugated – Sinusoidal or rounded wave pattern. Provides impact resistance and flexibility.

- Shingle Replicate – Formed rows mimic overlapping asphalt shingles. Offers visual appeal.

- Paneled – Flat or lightly ribbed panels combined with deep ribs. Improves appearance with stronger ribs.

- Diamond – Raised diamond pattern with distinct lines. Provides a decorative embossed look.

Manufacturers design custom roll forming dies to produce roofing with unique profiles and geometric detailing. Roll formed panels provide versatility to achieve desired aesthetics and performance.

Key Benefits of Roll Formed Roofing

Switching to roll formed metal roofing provides many advantages over other roofing materials:

Durability – Metal roofs withstand weather, impacts, and time better than shingles or membranes. Roll formed panels last 50+ years.

Lightweight – Thin metals like steel, aluminum, and titanium are much lighter than shake, tile, or other heavy roof coverings. This reduces roof load.

Resistance – Factory finishes resist rust, UV damage, fade and chalking. Roof finishes maintain appearance.

Energy Efficiency – Reflective metal roofing can reduce cooling costs. Standing seam allows insulation to be added.

Customization – Roll forming allows limitless panel shapes, textures, and colors for unique roofs.

Sustainability – Metal is recyclable. Cooler roofs also lower urban heat island effects.

Cost – Roll formed roofing provides economy compared to other premium long-lasting roof types.

With the versatility of roll forming, manufacturers can produce durable and attractive metal roofing to meet any need.

Components of Roll Forming Lines

A complete roll forming line contains a coordinated sequence of processing components beyond just the roll former itself. This allows high-volume, automated, continuous production of finished roof panels.

Typical line components include:

Uncoiler

The large uncoiler holds and dispenses the coils of flat sheet metal to start the process. It smoothly unrolls stock into the roll former.

Feeder Section

Feeders include straighteners, guides, and entry tables that prepare and correctly feed the metal sheet before roll forming.

Roll Forming Machine

The roll former shapes the metal profile through a series of roller stations that make incremental forming bends in the moving sheet metal.

Hydraulic System

The hydraulic power unit drives the roller stations and actuators for precision control during forming. Hydraulics allow quick die changeover.

Flying Cutoff

A fast-cycling cutoff saw or shear makes precise cuts at high speed to cut formed profiles to length as they exit the roll former.

Discharge Tables

Discharge tables provide a surface to smoothly collect cut metal panels as they exit the cutoff machine. This keeps line speed uninterrupted.

Control System

Automated programmable controls coordinate the sequence, speed, and synchronization of the entire forming line for optimal throughput and consistency.

Auxiliary Equipment

Additional auxiliary equipment can be integrated for material handling, stacking, labelling, and other automated tasks downstream of the roll former.

With coordinated layout and design, the complete process efficiently produces high volumes of formed roof panels ready for installation.

Setting Up a Roof Roll Forming Line

When installing a new roof roll forming line, proper setup and commissioning ensures smooth production. Follow key steps:

1. Set Equipment Locations

Arrange equipment in sequence to optimize material flow from coil payoff through formed panel discharge. Check clearances for material handling.

2. Install and Level Machines

Set machines on foundations, bolt down, and use laser levels to properly level the equipment. This prevents casting distortion during operation.

3. Connect Utilities

Run and connect electrical, hydraulic, and compressed air lines to power the roll former and auxiliary equipment. Verify pressures and voltages.

4. Thread Material

Thread the lead end of the coil through the machines for forming. Confirm the material aligns correctly through the process.

5. Inspect Rolls and Dies

Confirm roll and die clearances are properly set. Check for any shipping damage. Test run the machines.

6. Calibrate Sensors

Calibrate and test any sensors, encoders, scanners, and gauges to dial-in tolerances and communicate with control system.

7. Debug Controls

Debug the automation system to ensure correct sequence, timing, speeds, and actuation to produce right panels.

8. Initiate Trial Runs

Run production trials and adjust setup as needed to achieve full quality panels at production speed.

With proper installation and startup, the roll forming line will perform reliable high-volume roof panel production. Partner with experienced roll forming experts for the best results.

Maintenance of Roof Roll Forming Machines

Like any high-speed manufacturing machinery, regular preventive maintenance protects the investment in a roof roll forming line and avoids unexpected downtime. Follow these best practices:

- Inspect roll tooling daily and replace worn or damaged components proactively

- Lubricate bearings, gears, chains, and guides as specified

- Verify hydraulic system oil level, filter conditions, leaks

- Confirm pneumatic system water trap, lubricator, and filter status

- Complete full cleanings to remove metal chips, fines, grime from machining

- Check autoreverse units and safety limit switches for functionality

- Confirm electrical cabinet cleanliness and heat dispersion

- Test operator e-stops and interfaces for performance

- Audit sensors, encoders, and scanners for calibration

- Monitor machine vibration, noise, temperature changes

- Review automation system communication and I/O points

Preventive maintenance should follow the equipment manufacturer’s recommendations for periodic scheduling and replacement intervals for wear items.

Always use proper lockout/tagout procedures during maintenance to ensure de-energized and safe conditions.

Partnering with experienced mechanics and electricians helps keep roof roll formers running in peak condition for maximum return on investment.

Tips for Optimizing Roof Roll Forming Production

Qualified operators and process engineers can optimize set up and operation of roof roll forming lines to achieve high-quality output with maximum throughput. Useful tips include:

- Select compatible metal material and thickness to meet product design needs

- Maintain consistent coil stock to minimize machine adjustments

- Stage coils properly to fit equipment layout and avoid bridling

- Keep coils clean and dry to avert dirt entry problems

- Program adequate loop control into the process for stable web tension

- Adjust guides, rolls, and dies symmetrically to thread material straight

- Use entry tables to support metal and provide pre-forming of edges

- Set precise roller alignments and minimal clearances along forming path

- Balance pressures across roller stations to distribute stresses evenly

- Control forming speeds to suit metal type, thickness, and desired quality

- Apply protective lubricants or oils to avoid scratching soft metals

- Inspect and pack panels promptly to prevent damage after forming

- Document process settings to aid production optimization and repeatability

With attention to key parameters, operators can dial-in forming lines to produce quality roof panels at the maximum possible rate. Consult roll forming experts when launching new products.

Roll Forming vs Other Metal Roof Production Methods

For manufacturers evaluating process options, roll forming provides advantages over other metal roof panel production alternatives:

Roll Forming

- Highly efficient continuous process

- Flexible equipment adjusts for design changes

- Lower equipment investment cost

- Ideal for high-volume production

- Consistent quality along full length

- Suitable for long narrow panels

- Applicable to various metals

Press Brake Forming

- Batch process requires stops and starts

- Only short to mid run production

- Higher equipment cost for large presses

- Limited flexibility for design changes

- Quality varies across formed length

- Difficult for long narrow panels

- Metals can springback after forming

Stamping

- Design-specific dedicated tooling

- Very high cost for custom tooling

- Only beneficial for extremely high volumes

- Lack flexibility for variations

- Stamping stresses can distort metal

- Significant lead time for die fabrication

- Secondary operations often required

For most manufacturers, roll forming provides the optimum process for metal roof production. The flexibility, efficiency, and cost-effectiveness delivered by roll forming lines make it the go-to fabrication method in the industry.

Typical Specifications of Roof Roll Forming Machines

Roof roll formers come in different configurations to suit specific production needs. Key specifications buyers evaluate include:

Line Speed – 10 to 200 feet per minute or higher

Metal Width – 18 to 80 inches wide coils

Metal Type – Galvanized steel, aluminum, etc.

Metal Thickness – 20 ga to 14 ga (0.8 mm to 2.0 mm)

Drive Type – Electric or hydraulic motors

Cutting Method – Rotary shears or saws

Forming Sections – 10 to 30 roller stations

Profile Shape – Standing seam, ribbed, corrugated, etc.

Conveyor Type– Chain carry, power belt, etc.

Line Control – PLC, HMI, automatic operation

Added Functions – Embossing, punching, notching

Safety Features – Guarding, e-stops, alarms

Buyers select roof roll formers that match their production goals for width, speed, and capabilities.

Buying Considerations for Roof Roll Forming Equipment

Organizations investing in new roof panel roll forming equipment should evaluate options using these key considerations:

- Product Design – Match equipment capabilities to needed panel profiles, materials, widths, and lengths.Factor in any secondary operations.

- Production Volume – Determine expected volume. Higher volumes justify automation investment.

- Line Speed – Calculate required output rate to meet production targets and profit goals per shift.

- Metal Properties – Ensure the roll former can run the desired metal material thicknesses and strengths.

- Die Flexibility – Select machines that allow fast die changeover to produce varied or evolving panel designs efficiently.

- Equipment Cost – Weigh capital cost versus production value. Higher automation has higher cost but yields lower operating cost per panel.

- Space Requirements – Factor in equipment length plus safe material handling distances and clearance.

- Utilities – Confirm sufficient power supply, compressed air, and other utilities to operate the roll line.

- Controls – Modern programmable automation increases capability, precision, and throughput.

- Support – Look for manufacturers that provide installation support, training, and responsive service.

Evaluating these factors helps buyers select the ideal roof roll forming machine to maximize return on investment.

Trends in Roof Roll Forming Technology

Roof roll forming equipment continues evolving with new technology trends that improve manufacturing efficiency, quality, and capabilities:

- Servo-Driven Lines – Servo motors improve speed control, energy efficiency, and fast die changeovers.

- In-Line Notching – Adding in-line plate notching creates roofing system connections in one process.

- Vision Systems – Cameras and sensors inspect material alignment and ensure process control.

- Quick Die Change – New tool-less die systems enable rapid profile changes in 10 minutes.

- Material Handling – Automated decoilers, stackers, and conveyors improve material flow.

- System Integration – Seamless software integration yields detailed production monitoring and analysis.

- Safety – Enhanced safeguarding, emergency stops, and safety circuits prevent hazards.

- Quality Assurance – Sensors provide real-time quality monitoring for fault detection.

- E-Coating – Liquid systems allow in-line painting and coating to finish panels.

- IoT Connectivity – Smart networked machines enable remote monitoring and data collection.

With innovation, roll forming becomes an even more agile and efficient process for premium roofing production.

Tips for Selecting a Roof Roll Former Manufacturer

Choosing the right roll forming equipment partner ensures smooth project execution. Key selection criteria include:

- Experience – Look for extensive background in roofing applications with proven machines.

- Testing – Manufacturer should offer material trials and test runs to validate performance.

- Reliability – Opt for established manufacturers with reputation for quality and durability.

- Range – Seek broad equipment line to handle varied needs from entry level to high-end.

- Customization – Manufacturer should accommodate special requirements and integration needs.

- Support – Check maintenance services, manuals, warranties, and availability of parts.

- Training – Supplier should provide complete operation and maintenance training.

- Upgrade Path – Future expansion, retrofits, and improvements should be feasible.

- Delivery – Manufacturer must be able to meet procurement timeline expectations.

Choosing an ideal partner helps buyers get the right roll former for their roofing products and business goals.

FAQ

Q: How long does a roof roll forming machine typically last?

A: With proper maintenance and operation, a quality roll former will provide 20+ years of productivity. Key parts and components can also be replaced and upgraded as needed.

Q: Can I add other secondary processing after roll forming?

A: Yes, many manufacturers integrate additional inline processing like punching, drilling, embossing, curving and molding after roll forming. This creates completed ready-to-install panels.

Q: What factors affect the line speed of a roof panel roll forming machine?

A: Key factors influencing maximum line speed include material thickness/strength, profile complexity, number of roller stations, feeding consistency, and desired quality level.

Q: Should I buy new or used roof panel roll forming equipment?

A: For new manufacturers, buying quality pre-owned equipment can be an economical way to start production. Be sure to fully evaluate machine condition and remaining lifespan first.

Q: What kind of warranty comes with new roof panel roll formers?

A: Reputable manufacturers will offer a standard 12 month warranty on new equipment. Optional extended warranties are also available up to 5 years to protect buyer’s investment.

Q: What is the recommended maintenance schedule for a roof panel roll former?

A: Follow the manufacturer’s maintenance instructions, but in general:

- Daily checks – Inspect roll condition, lubricate, cleanup

- Weekly – Hydraulics inspection, verify pressures

- Monthly – Inspect chains, bearings, safety devices

- 6 Months – Change hydraulic oil and filters

- Annual – Grease bearings, inspect for wear, test automation

Q: Should I hire the manufacturer to install my new roof roll forming line?

A: Yes, it is highly recommended to use the manufacturer’s expertise for machine delivery, installation, and commissioning. This gives the best outcome and avoids issues.

Q: What is the typical lead time for purchasing a new roof panel roll former?

A: Lead time varies by manufacturer and demand, but plan for around 14 to 20 weeks from order to delivery in most cases. Custom machines may take longer.

Q: What factors determine the number of roll forming stations needed?

A: More complex, deeper profiles require more roll stations to complete the sequential bending. Typical station quantity is 12 to 24. The manufacturer will specify based on the design.

Q: How thick of metal sheet can a roof roll former accommodate?

A: Standard roll formers handle metal thickness from 0.6 mm to 2 mm (24 ga to 14 ga). Special models are available to form thicker metals up to 4 mm if required.