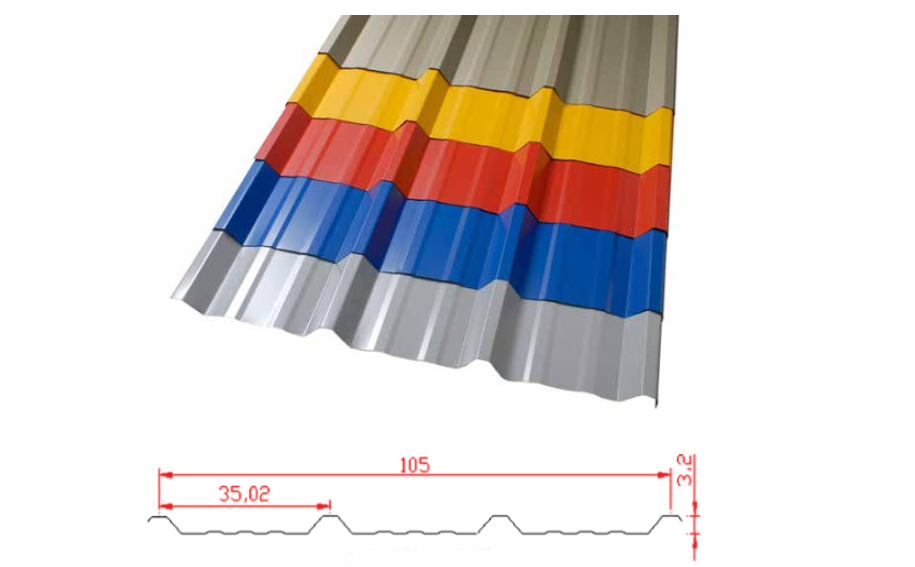

Color steel roll forming machine can produce material thickness range 0.3-0.8mm or 0.12-0.4mm, material PPGI, galvalume steel and galvanized steel, also we can customize the machine according to your drawing.

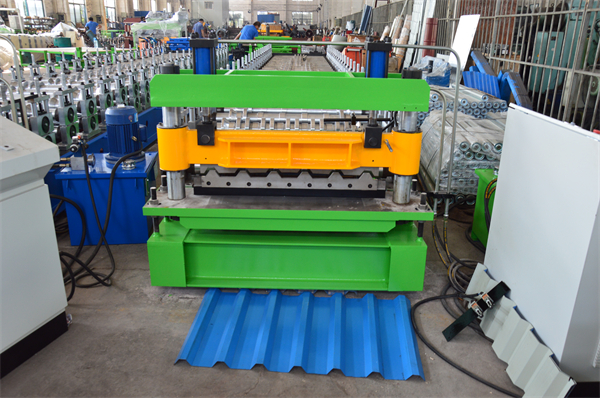

This machine design is unit one, which means the control box and motor are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. It saves more time and space.

Profile Drawing

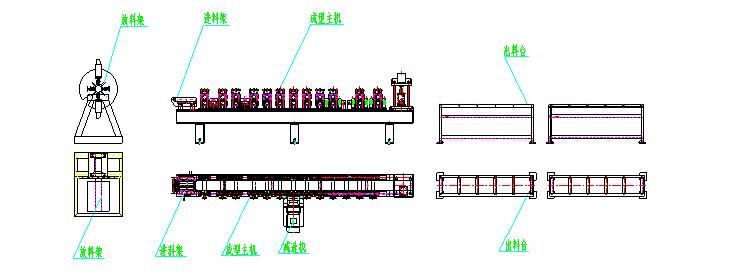

Technological process

Uncoiling—Feeding with guide—Roll forming—Cutting—Products collecting

|

Machine list

|

5 tons passive de-coiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| Control box | 1 unit | |

| Hydraulic cutting device | 1 set | |

| Out tables | 2 units | |

| Safety cover | 1 set | |

| Spare parts | 1 set |

The main description

| Items | Specifications | |

|

Material of coil

|

Material Thickness | 0.3—0.8mm PPGI, Aluzinc, galvanized steel |

| Un Coiler | 5 tons manual | |

|

Forming system

|

Rolling Speed | About 8-12m/min |

| Roller Stations | About 20 stations | |

| Roller material | 45# steel, coated with chrome | |

| Maim Motor Power | 7.5kw | |

| Hydraulic cutting Power | 4kw | |

|

Cutting

system |

Material Of Cutting | CR12Mov with quench treatment |

| Hardness | HRC58-62 | |

| Tolerance | ±1.5mm | |

|

Electrical control system

|

Electric Source | 380V, 50HZ,3 phase Also can satisfy customer’s require |

| Control System | PLC with touch screen | |

| Way Of Drive | single chain | |

| Color of the machine | Customized | |

| Machine size | About 9500*1600*1200mm |

Technical Data

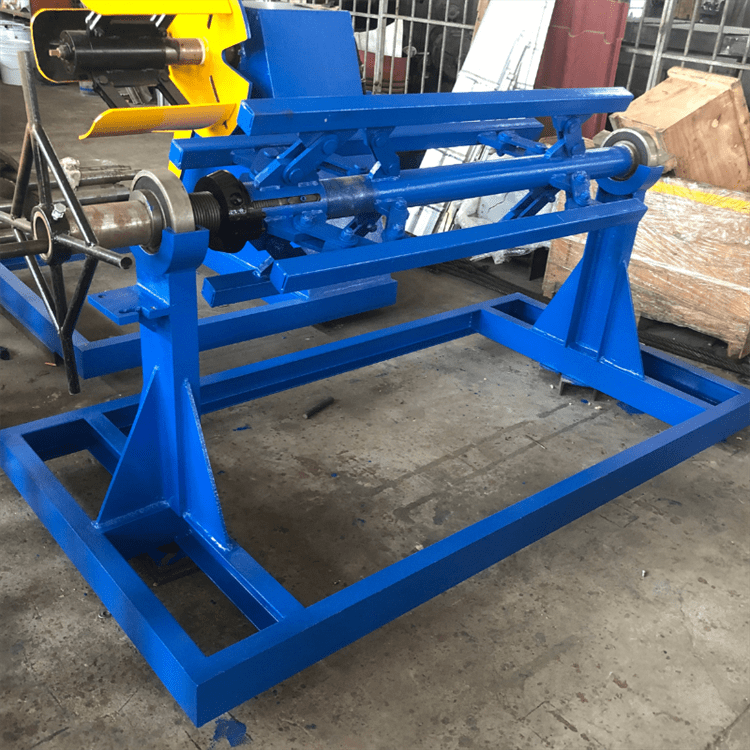

1. Decoiler

- 5 tons passive decoiler

- Coil inner Diameter: ¢460mm~520mm

- Max out diameter of the coil: ¢800mm

- Expansion: with 4 palms, with brake

- Max Coil Width: 500mm

2. Cutting

- Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

- Material of blade: CR12Mov with heat treatment

- Length measuring: Automatically

- The cutting thickness: 0.3- 0.8mm

- Hydraulic Station Power: 4 KW

3.Out table

- It adopts welded steel and supported roller to transmit the products, which is used to collect the finished products.

- Length : 2 meters

4. Control Box

- Power supplier: 380 V, 50 Hz, 3Phase (adjusted with the requirement)

- Length & quantity measurement automatically;

- Length & quantity controlled by PLC

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- Unit of length: millimeter (switched on the control panel)

Application of color steel roll forming machine

Color steel roll forming machines are used in the manufacturing process of color-coated steel sheets or coils. These machines have various applications in the construction, automotive, and appliance industries. Here are some common applications of color steel roll forming machines:

- Roofing and Cladding: Color steel roll forming machines are extensively used in the production of roof and wall cladding systems. These machines can create profiled sheets with different shapes and sizes, which are then used for roofing and cladding purposes in residential, commercial, and industrial buildings.

- Garage Doors: Color steel roll forming machines are employed to manufacture garage doors. These machines can produce steel panels with specific patterns and dimensions, which are then assembled into durable and visually appealing garage doors.

- Fencing and Enclosures: Roll-formed steel sections produced by color steel roll forming machines are widely used in the construction of fences, gates, and enclosures. These sections offer strength, durability, and aesthetic appeal, making them suitable for both residential and commercial applications.

- Storage Systems: Color steel roll forming machines are used in the production of components for storage systems such as shelves, racks, and cabinets. The roll-formed steel sections provide the necessary structural support and allow for easy assembly and customization of storage solutions.

- Automotive Components: Color steel roll forming machines play a vital role in the manufacturing of automotive components. They are used to produce sections and profiles for applications such as car body panels, structural reinforcements, and interior trim components.

- HVAC Ducting: Color steel roll forming machines are utilized in the production of ducting systems for heating, ventilation, and air conditioning (HVAC) applications. These machines can form the steel sheets into specific shapes and sizes required for efficient air distribution in buildings.

- Electrical Enclosures: Roll-formed steel sections produced by color steel roll forming machines are used in the fabrication of electrical enclosures and control cabinets. These sections provide protection, rigidity, and modularity for housing electrical components.

- Solar Panel Mounting Systems: Color steel roll forming machines are employed to manufacture mounting systems for solar panels. These systems consist of specially designed profiles that securely hold and position the solar panels on rooftops or in solar farms.

These are just a few examples of the applications of color steel roll forming machines. The versatility of these machines allows for the production of a wide range of customized steel profiles and sections, catering to various industries and product requirements.

What is steel door frame roll forming machine?

- Roll Forming System: The heart of the machine is the roll forming system, which consists of a series of rollers and dies. These rollers gradually shape the steel coil into the desired door frame profile. The number and arrangement of rollers may vary depending on the specific profile being produced.

- Decoiler: The machine is equipped with a decoiler that holds and feeds the steel coil into the roll forming system. The decoiler unwinds the coil and supplies a continuous strip of steel for the roll forming process.

- Cutting Mechanism: Once the steel strip is formed into the door frame profile, a cutting mechanism is used to cut the profile to the required length. This can be either a shear or a flying cutoff mechanism, depending on the machine design.

- Punching and Embossing Units: Some steel door frame roll forming machines are equipped with punching and embossing units. These units can punch holes or slots in the door frame profile for hardware installation and create embossed patterns or company logos for aesthetic purposes.

- Control System: The machine is controlled by a computerized control system. It allows operators to set various parameters such as length, speed, and batch quantity. The control system ensures precise and consistent production of door frame profiles.

- Material Handling System: The machine may include a material handling system that assists in the movement of the steel coil and finished door frame profiles. This can include conveyor belts, stackers, or other mechanisms to facilitate efficient production.

function of light gauge steel roll forming machine

The primary function of a light gauge steel roll forming machine is to automate the production process of light gauge steel profiles. Light gauge steel refers to thin steel sheets or strips that are typically less than 3mm in thickness. Here are the key functions and benefits of a light gauge steel roll forming machine:

- Profile Formation: The machine utilizes a series of rollers and dies to shape the light gauge steel strip into specific profiles. The rollers gradually bend and form the steel strip according to the desired shape and dimensions. The machine can produce a wide range of profiles, including C-sections, U-sections, hat channels, angles, and more.

- Material Handling: The machine is equipped with a decoiler that holds and feeds the steel strip into the roll forming system. The decoiler unwinds the steel strip from a coil, ensuring a continuous and smooth supply of material during the production process.

- Precision and Consistency: The machine’s roll forming system ensures precise and consistent production of light gauge steel profiles. The rollers and dies are designed to create accurate shapes and dimensions, ensuring uniformity throughout the produced profiles. This precision is essential for proper fitment and efficient assembly during construction or manufacturing processes.

- Speed and Efficiency: Light gauge steel roll forming machines offer high production speed and efficiency. The automated process eliminates the need for manual labor, resulting in faster production cycles and increased output. This makes the machines suitable for large-scale manufacturing projects where high volumes of light gauge steel profiles are required.

- Flexibility and Customization: Light gauge steel roll forming machines can be adjusted to produce different profiles and sizes according to specific project requirements. The machine’s flexibility allows for easy customization, enabling manufacturers to meet various customer demands and adapt to changing market trends.

- Cost Savings: Light gauge steel roll forming machines offer cost savings in several ways. Firstly, the automation reduces labor costs associated with manual profile formation. Secondly, the precision and consistency of the machine’s production process minimize material waste, leading to efficient utilization of the steel strip. Additionally, the high production speed and output of the machine contribute to overall cost savings.

Light gauge steel roll forming machines find applications in various industries, including construction, automotive, furniture, and more. They are commonly used for the production of stud and track systems, roof trusses, wall panels, suspended ceilings, partition walls, and other lightweight structural components.

Reviews

There are no reviews yet.