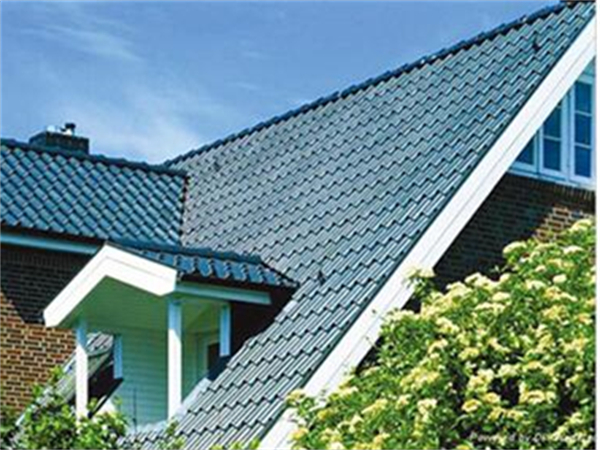

Станок для формирования рулонов металлочерепицы может производить материал толщиной 0,3-0,8 мм, материал PPGI, гальванизированная сталь и оцинкованная сталь. Станок для формирования рулонной металлочерепицы Step glavanized glazed tile используется для производства стальных листов различных профилей, работает под управлением PLC, можно отрезать любую длину, которую вы хотите.

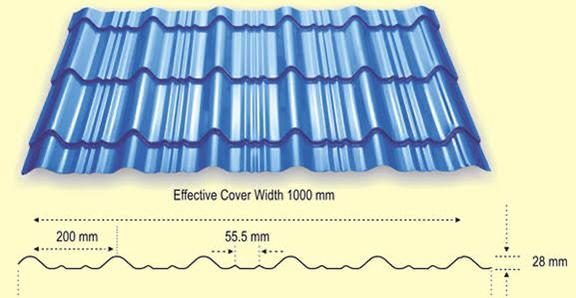

Чертеж профиля машины для формовки рулонной металлочерепицы

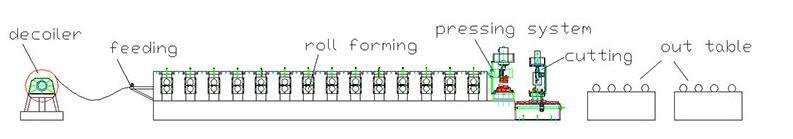

Технологический процесс рулоноформовочной машины для производства металлочерепицы

Размотка-кормление-руководство-рольформинг-прессование-резка-продуктов-коллекционирование

|

Список машин

|

5 тонн ручной разматыватель | 1 комплект |

| Пресс-форма | 1 комплект | |

| Основная профилегибочная машина | 1 комплект | |

| Гидравлическое режущее устройство | 1 комплект | |

| Устройство гидравлического пресса | 1 комплект | |

| Блок управления ПЛК | 1 блок | |

| Гидравлическая станция | 1 блок | |

| Таблица пассивных выходов | 2 единицы | |

| Запасные части | 1 комплект |

Основная статья

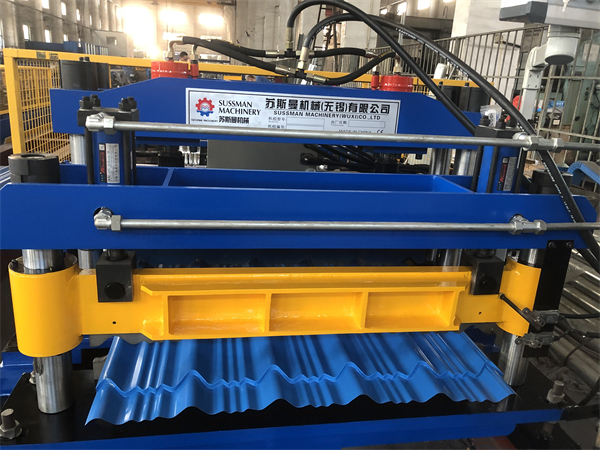

Станки для формовки глазурованной стальной черепицы являются самостоятельной разработкой нашей компании и имеют отличительные технологические характеристики.

Станки для формовки рулонной черепицы из глазурованной стали имеют изысканную конструкцию и привлекательный внешний вид, совершенная компьютерная система управления и дружественная операционная система сенсорного экрана делают эксплуатацию оборудования и установку данных очень удобными, у пользователя не возникает никаких проблем.

Станки для формовки рулонных плиток из глазурованной стали оснащены отличным вспомогательным оборудованием.

Процесс производства совершенного вспомогательного оборудования выглядит следующим образом:

Основное описание машины для формовки рулонной металлочерепицы

1. Разматывание:

- 5 тонн пассивного деоилера

- Внутренний диаметр рулона: ¢450-550 мм

- Максимальный диаметр катушки: ¢1500 мм

- Максимальная ширина катушки: 1250 мм

2. Рулонная формовочная машина

- Толщина листа цветной стали: 0,3~0,8 мм Цветной лист и оцинкованный лист

- Роликовые станции: Около 18 станций

- Способ привода: 1,2-дюймовая одинарная цепь

- Скорость работы вальцовочного станка: 8-12 м/мин

- Материал ролика: Кузнечная сталь 45#, покрытая хромом

- Материал вала и DIA: ¢76 мм, материал - кузнечная сталь 45#

- Мощность основного двигателя: 7,5 кВт Погрешность расстояния резки глазурованной плитки: ±1-2 мм

- Рулонная формовочная машина: Около 9000мм×1600мм×1500мм

- Станок для формовки рулонов: Около 8000 кг

3. Детали пресса

- Тип:Гидравлический

- Мощность гидравлической станции: 5,5 кВт

- Размер частей пресса: 1500*600*1200 мм

4. Режущие части

- Тип: Гидравлический

- Макс. толщина резки: 0,3-0,8 мм

- Мощность гидравлической станции: 5,5 кВт

- Автоматический гидравлический отрезной станок: Около 400мм×1500мм×1100мм

- Материал резки: Cr12Mov закалка 58-62℃

5. Выносной стол

Размер выносного стола: 2000*1350*1000м

6. Блок управления ПЛК

(1) Источник питания: 380 В, 50 Гц, 3 фазы (регулируется в зависимости от требований)

(2) Автоматическое измерение длины и количества;

(3) Длина и количество контролируются ПЛК

(4) Неточность длины можно легко исправить.

(5) Панель управления: Кнопочный переключатель и сенсорный экран

(6) Единица измерения длины: миллиметр (включается на панели управления)

Что такое шипорезная машина?

Вальцовочная машина для изготовления шпилек - это тип промышленного оборудования, используемого для изготовления металлических шпилек или рам, применяемых в строительстве. Он предназначен для эффективного производства однородных высококачественных металлических шпилек путем непрерывной гибки и формовки металлических рулонов в требуемую форму.

Работа станка заключается в подаче металлического рулона на ряд вальцовочных станций, каждая из которых оснащена комплектами роликов и матриц. По мере прохождения рулона через эти станции ролики постепенно придают металлу нужную форму и формируют необходимый профиль шпильки. Как правило, процесс автоматизирован, что позволяет непрерывно производить шпильки с минимальным ручным вмешательством.

Станки для вальцовки шпилек могут работать с различными видами металла, например, со сталью или алюминием, и позволяют изготавливать шпильки различных размеров и профилей в соответствии с конкретными строительными требованиями. В итоге на выходе получается длинная непрерывная шпилька, которая впоследствии может быть разрезана на более короткие отрезки.

Эти машины обладают рядом преимуществ с точки зрения эффективности и экономичности. Они могут производить шпильки с высокой скоростью, обеспечивая бесперебойные поставки на строительные объекты. Кроме того, процесс валковой формовки позволяет добиться постоянства размеров и качества, сократить отходы материала и повысить эксплуатационные характеристики изделий.

Вальцовочные станки для производства шпилек широко используются в строительной отрасли, где металлические шпильки применяются для изготовления каркасов стен, перегородок и других конструктивных элементов. Автоматизация производственного процесса позволяет оптимизировать производство, повысить производительность и обеспечить точные технические характеристики продукции.

как использовать машину для вальцовки стальных шпилек?

Использование машины для вальцовки стальных шпилек обычно включает следующие этапы:

- Подготовка: Убедитесь, что станок правильно настроен и отрегулирован под конкретные размеры и профиль шипа, который вы собираетесь изготавливать. Это включает в себя регулировку зазоров между роликами, установку режущих ножей (при необходимости) и настройку правильных параметров на панели управления.

- Загрузка материала: Поместите рулон стали на разматыватель машины. Разматыватель удерживает рулон и подает сталь в рулонную машину. Убедитесь в том, что рулон правильно выровнен и надежно закреплен, чтобы предотвратить любые неудачи с материалом во время работы.

- Подача материала: Запустите машину и начните процесс подачи материала. Машина будет автоматически втягивать рулонную сталь в узлы формирования рулонов. Убедитесь, что материал подается плавно и остается выровненным в течение всего процесса.

- Процесс роликовой формовки: По мере прохождения рулонной стали через станции роликовой формовки ролики и штампы постепенно придают ей требуемый профиль шпильки. Количество станций и их конфигурация зависят от конкретного станка и конструкции шпильки. Панель управления станка позволяет контролировать и при необходимости регулировать скорость и другие параметры.

- Резка (если применимо): Некоторые рулонные машины оснащены встроенными системами резки, которые могут автоматически отрезать сформированные шпильки на требуемую длину. Если машина оснащена такой функцией, убедитесь, что режущие ножи правильно выровнены и отрегулированы для точной резки. Как правило, машина оснащена механизмом управления, определяющим длину каждого отреза.

- Сбор и штабелирование: После того как шпильки сформированы и нарезаны, они выгружаются из машины. Готовые шпильки можно собрать и сложить в штабель для дальнейшей обработки или упаковки. Убедитесь в том, что зона штабелирования организована таким образом, чтобы предотвратить повреждение готовых шпилек.

- Контроль качества: Регулярно проверяйте изготовленные шпильки на наличие дефектов и несоответствий. Проверяйте размеры, качество обработки поверхности и общее качество, чтобы убедиться в том, что они соответствуют требуемым спецификациям. При выявлении каких-либо проблем может потребоваться корректировка.

Важно ознакомиться со специальными инструкциями и рекомендациями, предоставленными производителем машины для вальцовки стальных шпилек. Всегда соблюдайте правила техники безопасности, в том числе надевайте соответствующие средства защиты и убедитесь, что станок выключен, прежде чем приступать к его обслуживанию или регулировке.

применение вальцовочного станка для изготовления металлических шпилек и направляющих

- Внутренние перегородки: Металлические стойки и направляющие широко используются для возведения внутренних перегородок в коммерческих зданиях, жилых комплексах и офисных помещениях. На вальцовочном станке изготавливаются металлические стойки и направляющие, необходимые для возведения таких перегородок, что обеспечивает долговечность и экономичность решения.

- Подвесные потолочные системы: Металлические шпильки и направляющие являются важнейшими компонентами подвесных потолочных систем. На валковой машине можно изготовить необходимые металлические швеллеры и направляющие, которые поддерживают потолочные плиты или панели, обеспечивая простоту монтажа и регулировки.

- Каркас для гипсокартона: Металлические стойки и направляющие также используются при изготовлении каркаса для гипсокартона, обеспечивая прочный каркас для крепления гипсокартона или других отделочных материалов. На вальцовочном станке изготавливаются металлические стойки и направляющие точных размеров, необходимых для каркаса этих стен.

- Несущие стены: Металлические шпильки могут использоваться в системах несущих стен, где они служат вертикальными опорами для восприятия структурных нагрузок. Станок для прокатки может производить более толстые шпильки, обладающие достаточной прочностью, чтобы выдерживать значительный вес и поддерживать общую конструкцию.

- Системы наружных навесных фасадов: Металлические стойки и направляющие используются для изготовления наружных навесных фасадов, которые представляют собой ненесущие стены, обеспечивающие защиту от атмосферных воздействий, теплоизоляцию и эстетический вид. На вальцовочном станке можно изготовить необходимые металлические элементы для этих систем, обеспечив точные размеры и профили.

- Каркасное строительство коммерческих и промышленных зданий: Металлические стойки и направляющие широко используются для каркаса коммерческих и промышленных зданий. Вальцовочная машина способна производить большой объем металлических стоек и направляющих, обеспечивая эффективное и быстрое строительство.

- Звукоизоляция стен: Металлические стойки в сочетании со звукоизолирующими материалами используются для создания звукоизолирующих стен в таких помещениях, как студии звукозаписи, театры или конференц-залы. Вальцовочная машина может производить шпильки и направляющие, облегчающие установку звукоизоляционных материалов.

- Стенки со сдвигом: Металлические стойки могут использоваться в системах сдвиговых стен для обеспечения поперечной устойчивости и противодействия ветровым и сейсмическим нагрузкам. На вальцовочном станке изготавливаются металлические стойки с точными размерами и профилями, необходимыми для возведения сдвиговых стен.

Преимущества покупки профилегибочной машины для металлической кровли на продажу

7 лучших профилегибочных машин для производства металлических кровель на рынке

Отзывы

Отзывов пока нет.