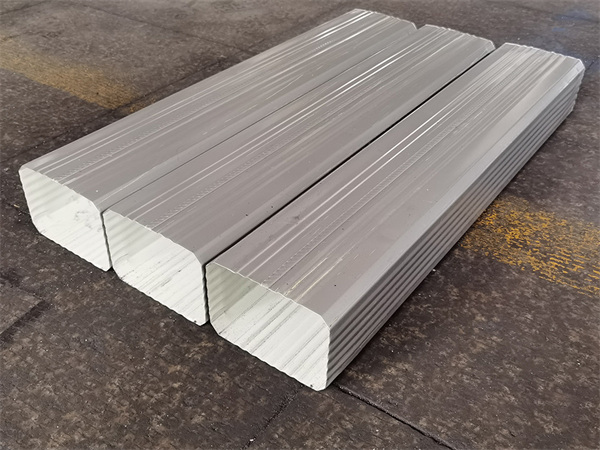

La profileuse pour tuyaux de descente de gouttières en acier, également appelée profileuse pour tuyaux de descente d'eau de pluie, a été conçue pour fabriquer des tuyaux de descente d'eau de pluie carrés ou ronds (circulaires ou rectangulaires). Le tuyau de descente est connu sous de nombreux noms tels que gouttière, tuyau de descente, tuyau d'évacuation, tuyau d'évacuation de toit, etc.

Les tuyaux de descente ronds et rectangulaires de la machine de formage de tuyaux de descente sont très populaires sur le marché.

Un tuyau de descente (Down pipe) est un tuyau permettant d'acheminer l'eau de pluie d'un toit ou d'une gouttière vers le sol ou vers un égout, également appelé Leader pipe, Down pipe, ou Drain spout. Les tuyaux de descente sont de plus en plus utilisés dans les solutions de stockage de l'eau de pluie.

La profileuse pour tuyaux de descente en acier peut produire des matériaux d'une épaisseur comprise entre 0,5 et 0,8 mm, des matériaux PPGI, de l'acier galvalume et de l'acier galvanisé. Nous pouvons également personnaliser la machine en fonction de vos dessins.

La conception de la profileuse pour tuyaux de descente en acier est unitaire, ce qui signifie que le boîtier de commande et le moteur sont tous placés sous le châssis de la machine. Lorsque vous recevez la machine, vous n'avez pas besoin d'assembler et de connecter les câbles compliqués de la machine, vous n'avez qu'à connecter un câble principal, puis la machine fonctionne. Cela permet d'économiser du temps et de l'espace.

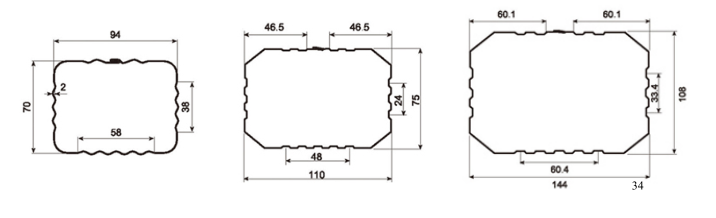

Dessin de profil

Paramètre technique

1. Spécification de la machine : épaisseur de formage 0,5-0,6mm, limite d'élasticité≤G550Mpa

2. Vitesse de formage : 5-10M/min (HORS TEMPS D'ARRÊT DE LA COUPE)

3. Diamètre du tuyau : selon le profil

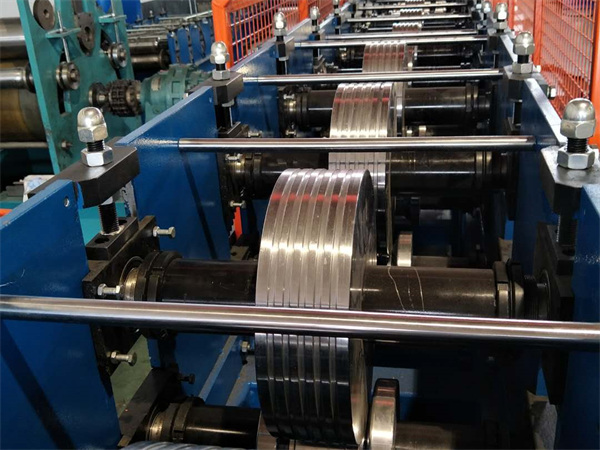

4. Rouleau de formage : environ 20 groupes

5. Puissance du moteur principal : 11KW

6. Puissance de la station hydraulique : 4KW

7. Matériau du rouleau : Acier forgé 45#, surface revêtue de chrome

8. Matériau de l'arbre principal : Acier 45#

9. Diamètre de l'axe principal : ¢68mm

10. Pression hydraulique de coupe : 10-12Mpa

11. Méthode de découpe : hydraulique, découpe après le profilage.

12. Matériau de la lame de coupe : Traitement de trempe Cr12Mov

13. Système de contrôle électrique : Toute la ligne est équipée d'un système de contrôle PLC, tolérance de coupe à la longueur≤2mm.

Ligne de profilage équipement compris

La ligne de formage de tuyaux de descente complets comprend un dérouleur manuel de 5 tonnes, un entraînement principal, un guidage d'entrée, une machine de formage de rouleaux, un dispositif de redressement, un équipement de coupe, un système hydraulique, un système de contrôle électrique, une table de sortie. Machine à couder et machine à sertir

Organigramme

Déroulage - Guidage de l'alimentation - Formage de rouleaux - redressage - Coupe hydraulique - Table de sortie - Couture coudée

Profil du produit

Données techniques de la machine à cintrer les coudes de descente de gouttière

A. Paramètres techniques

- Méthode de contrôle : contrôle du courant fort

- Puissance du moteur principal : 2,2KW

- angle du coude : 90

- Fonction supplémentaire : pliage et sertissage

- Dimensions de la machine à couder : 1200x650x1400mm

B. Photos de la machine pour référence

Qu'est-ce qu'une profileuse pour tuyaux de descente ?

Une profileuse pour tuyaux de descente est un équipement spécialisé utilisé dans le processus de fabrication des tuyaux de descente. Les tuyaux de descente, également appelés tuyaux de gouttière ou tuyaux d'eau de pluie, sont des éléments du système d'évacuation des eaux de pluie d'un bâtiment. Elles sont chargées de collecter et de diriger l'eau de pluie du toit vers un système d'évacuation approprié ou un réservoir de stockage.

La profileuse est conçue pour façonner les tôles en profils spécifiques pour les tuyaux de descente. Elle se compose d'une série de rouleaux et de matrices qui plient et façonnent progressivement la tôle pour lui donner la forme souhaitée. La machine fonctionne en alimentant continuellement la tôle en rouleaux, qui exercent une pression et la façonnent progressivement.

La profileuse pour tuyaux de descente est capable de produire des tuyaux de descente de différentes tailles, formes et configurations pour répondre à des exigences de conception spécifiques. C'est un moyen rentable et efficace de fabriquer des tuyaux de descente en grandes quantités, en garantissant une qualité constante et des dimensions précises.

Certaines machines avancées de profilage de tuyaux de descente peuvent être dotées de caractéristiques supplémentaires telles que des mécanismes de coupe pour couper les tuyaux de descente à la longueur souhaitée et des unités de perforation pour créer des trous ou des fentes afin de réguler le débit d'eau. Ces machines peuvent être personnalisées pour produire différents profils et peuvent incorporer des commandes automatisées pour améliorer la productivité et la précision.

Dans l'ensemble, la profileuse pour tuyaux de descente joue un rôle crucial dans le processus de fabrication des tuyaux de descente, permettant une production efficace et une qualité constante dans l'industrie de la construction.

Comment choisir une profileuse pour tubes carrés ?

Le choix d'une profileuse pour tubes carrés implique la prise en compte de plusieurs facteurs clés pour s'assurer qu'elle répond à vos besoins spécifiques. Voici quelques facteurs à prendre en compte lors de la sélection d'une profileuse pour tubes carrés :

- Taille et forme du tube : Déterminez la taille et la forme du tube carré que vous souhaitez produire. Tenez compte des dimensions, de l'épaisseur de la paroi et de tout profil spécifique ou personnalisation requis. Assurez-vous que la machine que vous choisissez peut traiter les spécifications du tube souhaité.

- Compatibilité des matériaux : Tenez compte du type de matériau que vous utiliserez pour le tube carré. Les matériaux les plus courants sont l'acier, l'acier inoxydable, l'aluminium et d'autres alliages. Assurez-vous que la machine est capable de former efficacement le matériau choisi.

- Capacité de production : Évaluez vos besoins de production en termes de volume de production escompté. Tenez compte de la vitesse de la machine, des stations de formage des cylindres et de l'efficacité globale du processus de production. Choisissez une machine capable de répondre à la capacité de production souhaitée.

- Options de personnalisation : Déterminez si vous avez besoin de fonctions supplémentaires ou d'options de personnalisation. Certaines machines peuvent offrir la possibilité d'incorporer des fonctions de poinçonnage, de découpe ou de gaufrage dans le processus de profilage. Évaluez si ces fonctions sont nécessaires pour votre application spécifique.

- Qualité et fiabilité de la machine : Évaluez la qualité globale, la durabilité et la fiabilité de la machine. Recherchez des fabricants réputés pour la qualité de leurs profileuses. Consultez les commentaires et les références des clients pour évaluer les performances et la fiabilité de la machine.

- Coût et budget : Tenez compte de vos contraintes budgétaires et comparez les prix des différentes machines. N'oubliez pas que l'option la moins chère n'est pas toujours la plus rentable à long terme. Comparez le prix de l'appareil avec sa qualité, ses caractéristiques et sa durabilité à long terme.

- Assistance technique et service après-vente : Évaluez l'assistance technique et le service après-vente fournis par le fabricant. Assurez-vous qu'il propose des formations, une assistance au dépannage et la disponibilité de pièces détachées pour soutenir vos opérations en cours.

- Caractéristiques de sécurité : La sécurité doit être une priorité. Recherchez des machines qui intègrent des dispositifs de sécurité tels que des boutons d'arrêt d'urgence, des protections et des certifications de sécurité appropriées.

- Flexibilité et polyvalence : Tenez compte de la capacité de la machine à s'adapter à différentes tailles ou formes de tubes. Si vous anticipez des changements potentiels dans les exigences de vos produits, choisissez une machine qui offre une facilité d'ajustement et une polyvalence.

Il est conseillé de consulter des fabricants ou des fournisseurs de profileuses réputés qui peuvent vous conseiller et vous recommander des machines adaptées à vos besoins spécifiques. Ils peuvent vous aider à évaluer vos besoins et vous suggérer la profileuse pour tubes carrés la mieux adaptée à votre application.

Combien coûte une machine à former des rouleaux de tuyaux de descente ?

Le coût d'une profileuse pour tuyaux de descente peut varier en fonction de plusieurs facteurs, notamment les spécifications, les caractéristiques et la qualité de la machine, ainsi que le fabricant ou le fournisseur. En règle générale, le prix d'une profileuse pour tuyaux de descente peut aller de quelques milliers de dollars à plusieurs dizaines de milliers de dollars.

Les machines moins complexes et de petite taille peuvent être disponibles à moindre coût, tandis que les machines plus grandes et plus avancées, dotées de fonctions supplémentaires et de capacités d'automatisation, sont généralement plus onéreuses.

Il est important de considérer que le coût de la machine n'est pas le seul facteur à prendre en compte. La qualité, la fiabilité, l'assistance technique et le service après-vente sont également des éléments cruciaux à prendre en compte lors de l'évaluation de la valeur totale de la machine.

Pour obtenir un prix précis et actualisé pour une profileuse pour tuyaux de descente spécifique, il est recommandé de contacter directement les fabricants ou les fournisseurs. Ils peuvent vous fournir des informations détaillées sur les spécifications et les prix de la machine en fonction de vos besoins spécifiques.

Avis

Il n’y a pas encore d’avis.