Omega profile roll forming machine can produce material thickness range 0.3-0.8mm or 0.12-0.4mm, material PPGI, galvalume steel and galvanized steel, also we can customize the machine according to your drawing.

Omega profile roll forming machine design is unit one, which means the control box and motor are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. It saves more time and space.

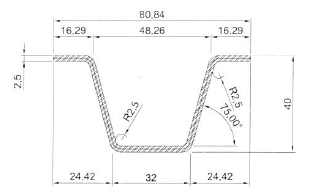

Profile Drawing of Omega profile roll forming machine

The thickness of sheet: 2.0-4.0mm

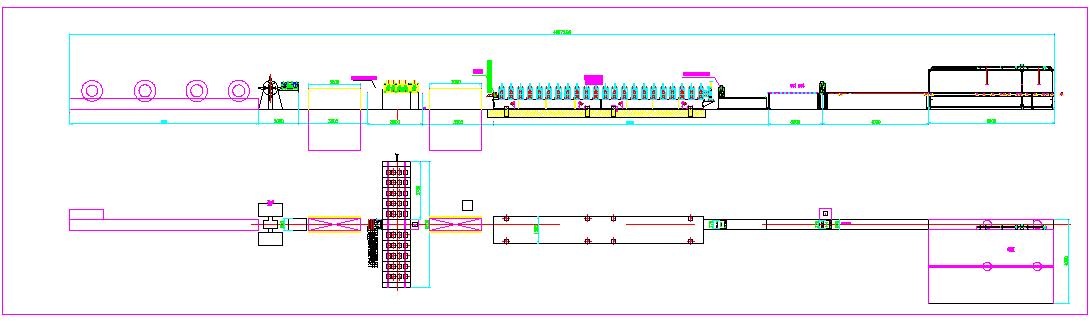

Production flow

De-coiling—Feeding&leveling—Servo feeder—Punching—rollforming—hydraulic cutting& bending—Belts— auto stacker

Layout

मशीन सूची

|

Machine lists

|

5 ton hydraulic Un-coiler and coil car with air arm | 1 सेट |

| Feeder and leveler | 1 सेट | |

| Servo feeder for punching device | 1 सेट | |

| हाइड्रोलिक पंचिंग डिवाइस | एक इकाई | |

| पंचिंग मोल्ड्स | 3 sets | |

| मुख्य रोल बनाने की मशीन | 1 सेट | |

| Servo following Cutting | 1 सेट | |

| ब्लेड काटना | 2 सेट | |

| नियंत्रण प्रणाली | एक इकाई | |

| हाइड्रोलिक स्टेशन | 2 यूनिट | |

| 3 meters belts conveyor | एक इकाई |

उपकरण की संरचना

1. 5 Tons Hydraulic de-coiler and coil car with arm

- स्वचालित हाइड्रोलिक सिस्टम को अपनाएं

- कुंडल वजन (अधिकतम): 5000 किग्रा

- Coil dia (Max):1600mm

- तेल सिलेंडर व्यास: 1200 मिमी काम का दबाव: 10mpa

- कुंडल चौड़ाई (अधिकतम): 500 मिमी

- Working speed: 0-25m/min

- पावर: 4KW

2. Feeding & leveling

- गाइड रोलर को शीट खिलाना (यह दाएं और बाएं से समायोज्य है)।

- Feeding roller: diameter is¢160mm; material is 40CR steel, HRC58-62.

- Leveling roller: upper is 3 rollers, down is 4 stations (total is 7 stations), material is 40CR steel, HRC58-62.

- लेवलिंग रोलर का व्यास: 180 मिमी

3. Servo Feeding device

Feeding Servo feeding motor: 5.5kw

Description: servo feeding can control the punching distance in precision, controlled by PLC, and the feeding tolerance can be+-0.5mm, the servo motor can control the speed, and can accept the input signal, and react quickly, and performance well, the touch screen can display the rotating speed, the length and the quantity, it can be controlled by the manual and auto modes.

4. Hydraulic Punching

- Using hydraulic punching, total about 3 sets of punching dies, no need to change the moulds, all the moulds are mounted in the bedding, just slide from the left to the right and Mark the Punching die numbers.

- Oil cylinder diameter:¢180mm

- काम का दबाव: 30mpa

- Mould material: Cr12mov quenched 58°-62°

- Hydraulicstation power: 30kw

5. Roll forming machine

- Main motor power: 22kw*2

- स्टेशन: कच्चा लोहा HT50 अपनाएं

- Driven system: gear box driving

- Main shaft diameter:¢90mm

- Material: 45﹟forge steel

- Roller material: Gcr15 quenched 58°-62°,chromed

- Roll station:according to the profiles

- Roller thickness: 4-6mm

- Timing by transducer:about 0-10m/min, according to profiles

- Voltage 380V,50HZ, 3 phases

6. Servo following Cutting

- Hydraulic non-stop Servo following cutting

- Knife material: Cr12mov,quenched 58°-62°

- तेल सिलेंडर व्यास: 250 मिमी

- काम का दबाव: 60mpa

- कार्य यात्रा: 80 मिमी

- Cutter Blades: about 2 sets

7. Control Box

Adopted PLC, transducer, touch panel to ensure high speed with stability, precision and lifetime. Other electric element are Schneider

- बिजली आपूर्तिकर्ता: 380V, 50 हर्ट्ज, 3 चरण (अनुरोध के साथ समायोजित)

- लंबाई और मात्रा माप स्वचालित रूप से;

- पीएलसी द्वारा नियंत्रित लंबाई और मात्रा

- लंबाई की अशुद्धि को आसानी से संशोधित किया जा सकता है।

- नियंत्रण कक्ष: बटन-प्रकार स्विच और टच स्क्रीन

- टच स्क्रीन में भाषा: अंग्रेजी और चीनी

- लंबाई की इकाई: मिलीमीटर (नियंत्रण कक्ष पर स्विच किया गया)

8. 3 Meters Rubber transportation Belts table

If you want to know the roll forming machine price list, please contact us.

What is profile roll forming machine?

A profile roll forming machine is a type of industrial machinery used in the manufacturing and fabrication of metal profiles with consistent shapes and dimensions. It is commonly employed in industries such as construction, automotive, and appliance manufacturing.

The roll forming process involves passing a continuous strip of metal through a series of rolls, which gradually shape the metal into the desired profile. The rolls are designed with specific contours and gradually bend the metal to achieve the desired shape. The profile roll forming machine typically consists of several sets of rolls, which can be adjusted to accommodate different profiles.

The machine operates in a continuous manner, with the metal strip being fed into the machine and the finished profile being discharged at the other end. Various operations, such as cutting, punching, and notching, can be incorporated into the machine to create additional features or holes in the profile.

Profile roll forming machines are highly customizable and can be configured to produce a wide range of profiles, including channels, angles, tubes, C and Z sections, and more. They offer advantages such as high production speeds, consistent quality, and the ability to work with a variety of metals, including steel, aluminum, and stainless steel.

Overall, profile roll forming machines are essential tools for efficiently manufacturing metal profiles used in various industries, providing cost-effective and precise production capabilities.

application of omega profile roll forming machine

- Building Construction: Omega profiles are widely used in the construction industry for framing and structural purposes. They are commonly employed as roof purlins, wall studs, and ceiling grids. Omega profiles provide strength, stability, and support to the building structure.

- Solar Panel Mounting Systems: Omega profiles are utilized in the fabrication of mounting systems for solar panels. These profiles act as rails or support structures, allowing solar panels to be securely mounted on rooftops or in solar farms. Omega profiles provide the necessary strength and durability to withstand various weather conditions.

- Racking and Shelving Systems: Omega profiles are ideal for creating sturdy and adjustable racking and shelving systems in warehouses, factories, and retail spaces. They are used to construct racks, shelves, and storage systems that can accommodate heavy loads and optimize space utilization.

- Door and Window Frames: Omega profiles are employed in the manufacturing of door and window frames. The profiles offer structural support, stability, and aesthetic appeal to the frames. They can be customized to fit different door and window sizes and provide a durable framework for the installation of glass panels.

- Automotive Industry: Omega profiles find applications in the automotive sector, particularly in the fabrication of vehicle frames, chassis components, and reinforcements. These profiles contribute to the structural integrity and safety of automobiles, providing a strong and lightweight framework.

- Electrical Enclosures: Omega profiles are used in the production of electrical enclosures, such as control panels, switchgear cabinets, and distribution boxes. The profiles offer a robust structure for housing electrical components and equipment, ensuring protection against environmental factors and electrical hazards.

what about c purlin roll forming machine price?

The price of a C purlin roll forming machine can vary depending on several factors, including the machine’s specifications, features, brand, and the supplier or manufacturer. Generally, C purlin roll forming machines range in price from several thousand dollars to tens of thousands of dollars.

The price can also be influenced by the complexity and capabilities of the machine. For instance, a basic C purlin roll forming machine that produces standard-sized C purlins may have a lower price compared to a machine with advanced features like automatic size adjustment, multiple profiles capability, and high-speed production.

To get an accurate price for a C purlin roll forming machine, it is recommended to contact multiple suppliers or manufacturers and request a quotation. They can provide you with specific pricing information based on your desired specifications and requirements.

It’s worth noting that the price of the machine is just one aspect to consider. Other important factors include the quality, reliability, after-sales support, warranty, and reputation of the supplier or manufacturer. It’s important to evaluate these aspects along with the price to make an informed decision and ensure you’re getting a machine that meets your needs and provides long-term value.

समीक्षा

अभी तक कोई समीक्षा नहीं।