Roof Wall panel roll forming machine for decorative can produce material thickness range 0.3-0.8mm, material PPGI, galvalume steel and galvanized steel, also we can customize the machine according to your drawing, specially the pitch and height of each wave, for the machine speed, we can do normal speed 8-12m/min.

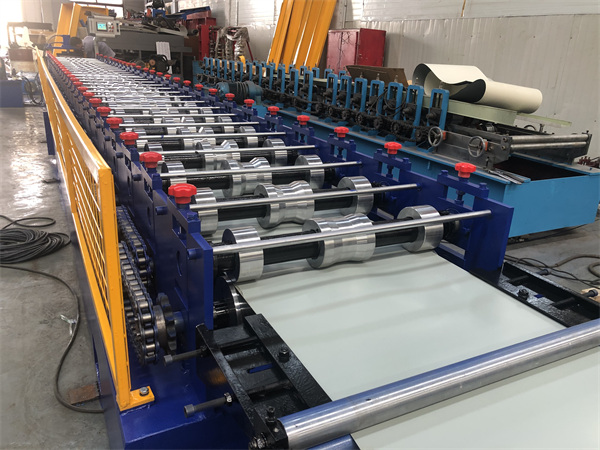

Roof Wall panel roll forming machine for decorative design is unit one, which means the control box and motor are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. It saves more time and space.

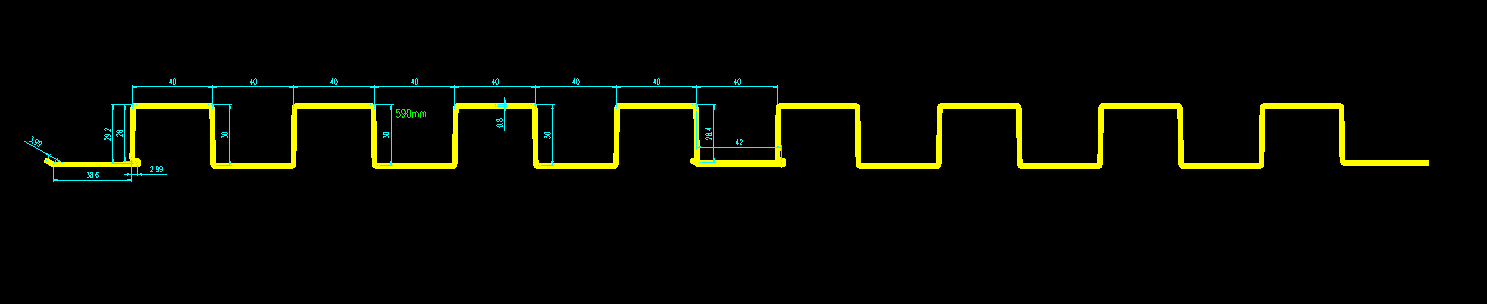

Profile Drawing of Roof Wall panel roll forming machine for decorative

Technological Process of Roof Wall panel roll forming machine for decorative

Uncoiling—Feeding with guide—Pre-cutting—Roll forming—Cutting—Products collecting

|

मशीन सूची

|

5 टन निष्क्रिय डी-कॉइलर | 1 सेट |

| Pre-cutting device | 1 सेट | |

| मुख्य रोल बनाने की मशीन | 1 सेट | |

| पीएलसी नियंत्रण बॉक्स | एक इकाई | |

| हाइड्रोलिक काटने का उपकरण | एक इकाई | |

| 4 meters out table | एक इकाई | |

| सुरक्षा कवच | 1 सेट |

Technical Data of Roof Wall panel roll forming machine for decorative

1. 5 Tons Hydraulic Un-coiler

- कुंडल भीतरी व्यास: ¢460-520mm

- Max out diameter of the coil: ¢1300mm

- Max Coil Width: 1250mm

2. Pre-cutting Device

3. Roll Forming Machine

- Rolling Speed: About 10-12m/min

- Steel sheetThickness: 3 mm to 0.8mm PPGI, Galvanized Steel

- Roller Stations:about 24 stations

- Roller Material : 45# forge steel, coated with chrome

- Shaft Material and DIA: ¢76mm,material is 45# forge steel, Chrome with quenching

- MainMotor Power:5kw

- Hydraulic Pressure:12Mpa

- Power supplier: 380V, 50HZ,3 phaseor customized as customer’s requirement

- Way Of Drive:bychain

- Color Of The Machine:blue or customized

- The size of the forming machine: About 10500*1000*1200mm

- Machine weight: about 10 tons

- Control system: PLC control panelwith touching screen

Our machine design is unit one, which means the control box and motor are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, then the machine is working. It saves more time and space.

4. Hydraulic cutting

(1) Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

(2) Material of blade: CR12Mov with heat treatment

(3) Length measuring: Automatically

(4) The cutting thickness: 0.3- 0.8mm

(5) Hydraulic Station Power: 4 KW

5. Out Table

It adopts welded steel and supported roller to transmit the products.

Size:4000*1350*1200mm

6. Control Box

(1) Power supplier: 380V, 50 Hz, 3Phase (adjusted with the requestment)

(2) लंबाई और मात्रा माप स्वचालित रूप से;

(3) Length & quantity controlled by PLC

(4) लंबाई की अशुद्धि को आसानी से संशोधित किया जा सकता है।

(5) Control panel: Button-type switch and touch screen

(6) Unit of length: millimeter (switched on the control panel)

Spare Parts

| नाम | संख्या | |

|

औजार

|

फ़ीलर गौज़ | 1 |

| आकार स्पैनर | 1 | |

| आंतरिक षट्भुज स्पैनर | 1 | |

| क्लैंप | 1 | |

| मानक स्पैनर | 1 | |

| शिफ्टिंग स्पैनर | 1 | |

| स्लॉटेड स्क्रूड्राइवर | 1 | |

|

अन्य सामान

|

ज़ंजीर | 2 pieces |

| असर (हारबिन) | 2 pieces |

What is roof and wall panel roll forming machine?

A roof and wall panel roll forming machine is a specialized industrial machine used in the construction industry to manufacture metal roof and wall panels. It is designed to automate the process of forming continuous metal sheets into specific profiles and shapes required for roofing and wall cladding applications.

The roll forming machine typically consists of a series of roller dies, which progressively bend and shape the metal sheet as it passes through the machine. The machine is equipped with various components, such as decoilers to hold the metal coils, leveling units to straighten the sheet, punching units for creating holes or slots, and cutting units for cutting the panels to the desired length.

The operation of the machine involves feeding the metal coil into the machine, where it is unwound and guided through the rollers. The rollers gradually shape the metal sheet into the desired profile, which can vary based on the specific requirements of the project. The finished panels are then cut to the desired lengths and stacked or collected for further processing or transportation.

Roof and wall panel roll forming machines offer several advantages in the construction industry. They provide high production efficiency, accuracy, and consistency in forming metal panels. They can produce panels of different lengths and profiles, allowing for customization according to project specifications. These machines are commonly used in the manufacturing of metal roofs, wall cladding, and other architectural applications where durable and aesthetically pleasing panels are required.

Overall, roof and wall panel roll forming machines are vital equipment in the construction industry, enabling the efficient production of metal panels used in various building projects.

application of roof wall panel roll forming machine

The application of roof and wall panel roll forming machines is primarily in the construction industry, where they play a crucial role in manufacturing metal panels for roofs and wall cladding. Here are some specific applications of these machines:

- Residential and Commercial Roofing: Roof panel roll forming machines are used to produce metal panels that are commonly used in residential and commercial roofing applications. These machines can create various profiles, such as corrugated, standing seam, and trapezoidal, which offer durability, weather resistance, and aesthetic appeal.

- Industrial Buildings: Metal panels manufactured by roll forming machines are widely used for wall cladding in industrial buildings, warehouses, factories, and other similar structures. These panels provide protection against weather elements, enhance insulation, and offer a sleek appearance to the building exteriors.

- Agricultural Buildings: Roll-formed metal panels are also utilized in agricultural buildings, such as barns, sheds, and storage facilities. These panels provide strength, durability, and resistance to corrosion, making them suitable for farm structures.

- Commercial and Retail Structures: The versatility of roof and wall panel roll forming machines allows for the production of customized panels used in commercial and retail buildings. These panels can be tailored to meet specific architectural requirements and design aesthetics, providing a visually appealing and durable solution.

- Infrastructure Projects: Metal panels manufactured by roll forming machines are used in infrastructure projects, including transportation hubs, stadiums, airports, and other large-scale constructions. These panels offer structural integrity, weather protection, and contribute to the overall aesthetics of the project.

- Residential Projects: Apart from commercial applications, roof and wall panels produced by roll forming machines are also used in residential projects. They are utilized for roofing, siding, and other exterior applications, offering durability, energy efficiency, and a wide range of design options.

Overall, roof and wall panel roll forming machines find extensive applications in the construction industry, providing cost-effective, efficient, and high-quality metal panels for various types of buildings and structures.

समीक्षा

अभी तक कोई समीक्षा नहीं।