Rain gutters are an important part of any building’s exterior system to manage rainwater runoff from the roof. Properly installed gutters direct water away from the structure to prevent damage. Roll forming machines are commonly used to manufacture standardized rain gutter profiles from metal coils in an efficient automated process. This guide provides a comprehensive overview of rain gutter roll forming machine types, main components, specifications, suppliers, applications, installation, advantages, and more.

Overview of Rain Gutter Roll Forming Machines

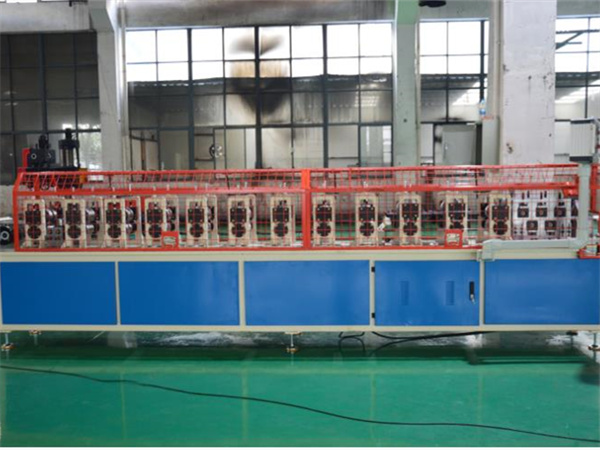

Roll forming is a continuous bending operation in which sheet or coil material is passed through consecutive sets of rollers to shape the material into various profiles. Rain gutter roll forming machines use this automated process to transform flat metal strips or coils into finished rain gutter profiles as per customized specifications.

Roll formed rain gutters have a uniform cross-section and can be cut to required lengths on site. They provide an economical way of producing rain gutters in long lengths with predefined patterns compared to traditional manual methods.

The key details of rain gutter roll forming machines are summarized below:

Roll Formed Rain Gutter Equipment Guide

| Machine Type | विवरण |

|---|---|

| रोल बनाने की मशीन | Primary equipment with roller stations for bending |

| डेकोइलर | Unwinds metal coil to feed rollers |

| Pinch rollers | Pulls material through roll forming stages |

| Cutoff knife | Cuts formed gutters to length |

| Supporting equipment | Punching, notching, embossing etc. |

Main Components of Rain Gutter Roll Formers

- Forming rollers – progressively shape flat strip

- Decoiler – feeds raw material from coil

- Guide rollers – support and align strip

- Pinch rollers – grip and pull metal through

- Cutoff device – cut formed gutters to length

- Control panel – adjust forming parameters

Key Characteristics of Rain Gutter Roll Forming Lines

- High automation for continuous production

- Flexible design customized for gutter profile

- Roller stages add stiffness and shape

- Suitable for high production volumes

- Can integrate functionalities like punching

- Requires less labor due to automation

Typical Specifications and Standards

| पैरामीटर | Details |

|---|---|

| Gutter thickness | 0.4 mm to 1.2 mm |

| Strip width | Up to 850 mm |

| Formed width | 150 mm to 400 mm |

| Feeding speed | 1 – 15 m/min |

| Metal type | Galvanized steel, aluminum etc. |

| Gutter types | K-style, half-round etc. |

| Length | Up to 10 meters |

Rain Gutter Roll Forming Machine Suppliers

Some top manufacturers of rain gutter roll forming equipment include:

- ACL Machinery (China)

- Gasparini S.p.A (Italy)

- Samco Machinery (Canada)

- Jupiter Rollforming (USA)

- Bradbury Group (UK)

- Dahezhongbang (China)

- SMOBY (Spain)

मूल्य सीमा

Small rain gutter roll forming lines can start around $30,000. Large automated systems with many added functionalities can cost over $200,000.

Applications and Use of Rain Gutter Roll Forming Machines

Rain gutter roll forming equipment has the following main applications in the metalworking industry:

Major Applications of Rain Gutter Roll Forming Machines

| आवेदन | विवरण |

|---|---|

| Rain gutter manufacturing | Primary use is mass production of rain gutters |

| Construction industry | For making gutters on-site for installing in buildings |

| Roofing contractors | To fabricate required lengths of gutters for roofing projects |

| Sheet metal industry | Multi-purpose use for various profiles besides gutters |

Roll formed rain gutters are widely used for:

- Residential homes

- Commercial buildings

- Agricultural structures

- Industrial facilities

Specification matching to intended application is important for proper functioning.

Working Principle of Rain Gutter Roll Forming Machines

The working principle involves continuously forming a flat metal strip into the desired rain gutter profile through multiple roller stations in a sequential bending operation:

- Coil is loaded on a powered decoiler which feeds the strip

- Strip passes through progressive roller dies for bending

- Rollers are independently driven and adjustable

- Sequential roller stations gradually shape the profile

- Pinch rollers grip and pull the strip through the stations

- Cutoff device cuts formed gutters to required length

- Control panel allows parameters like speed to be set

- Formed gutters are manually offloaded or conveyed out

Essentially, the strip undergoes a series of bends from the roller dies to incrementally achieve the final profile. The roll forming process is highly automated for continuous high-speed production.

Main Components of a Rain Gutter Roll Forming Machine

The key components of a complete rain gutter roll forming line are:

Components of a Rain Gutter Roll Former

| Component | Function |

|---|---|

| डेकोइलर | Holds coil of strip, powered to unwind |

| Roll forming mill | Progressive roller dies for bending |

| Pinch rollers | Pull strip through rollers |

| Guiding rollers | Support and align the strip |

| Cutoff device | Cuts formed gutters to length |

| कंट्रोल पैनल | To set and adjust parameters |

| Conveyors | Offload finished gutters |

डेकोइलर

- Holds large coil of thin metal strip

- Powered to unroll the coil to feed material into the roll former

- Braking system to provide desired tension

- Guides to align the strip

Roll Forming Mill

- Series of roller stations with custom profiling dies

- Each set of rollers make a bend to gradually form the gutter profile

- Number of roller stations is designed for profile complexity

- Rollers are powered and adjustable for precision forming

Pinch Roller

- Located between roll forming stations

- Grips and pulls metal strip through the rollers

- Usually has rough textured rubber coating to grip material

- Keeps constant tension on strip during forming

Guiding Rollers

- Placed between roller stations

- Provide support for thin metal strip

- Keeps strip aligned to pass smoothly through each station

Cutoff Device

- Cuts the finished rain gutter lengths as per specified size

- Can be manual, pneumatic, or servo powered

- Fixed or sliding cutoff options

Control Panel

- Used to set and adjust operational parameters

- Can control line speed, cutoff length, material thickness etc.

- Displays machine status indicators

- Some automated systems have touchscreen HMI

Conveyors

- Automatically offload cut rain gutters from the exit end

- Reduces manual handling requirements

- Facilitates faster production cycles

Specifications of Rain Gutter Roll Forming Machines

Rain gutter roll forming lines are customized to produce gutters as per required sizes and profiles. The main specifications include:

Typical Specifications of Rain Gutter Roll Formers

| पैरामीटर | Typical Range |

|---|---|

| Metal strip thickness | 0.3 mm to 1.2 mm |

| Strip width capacity | Up to 850 mm |

| Formed gutter height | 150 mm to 400 mm |

| Formed gutter width | 80 mm to 300 mm |

| Production speed | 1 to 15 m/min |

| Roller frame length | 6 m to 20 m |

| Roller qty | 15 to 50 stations |

| Drive power | 5 kW to 15 kW |

| मशीन वजन | 4000 kg to 10000 kg |

- Machines can be built for different metal materials like steel, aluminum etc.

- Specifications are designed to match intended rain gutter dimensions

- Higher roller stations for more complex gutter profiles

- Automated models have high speeds up to 15 m/min

Design and Construction of Rain Gutter Roll Forming Machines

Rain gutter roll formers have the following key design elements:

- Roller dies – Custom machined for desired gutter profile

- Roller frames – Robust frames to support roller stations

- Strip guides – Guide strip through machines smoothly

- Safety guards – Protect dangerous moving parts

- Automated features – Decoiler, conveyors, rapid cutoff

- Touchscreen HMI – For controlling machine parameters

- Modular configuration – Flexible options to add functionalities

Machine construction follows industrial standards:

- Heavy duty steel fabrication for rigidity

- Precision machined parts for roll dies and drivetrain

- Hardened gearing and bearings in roller drives

- Powder coated paint or galvanizing for durability

- Conforms to CE, ISO safety standards

The structural design and build quality ensure continuous operation, safety, and longevity.

Manufacturing Process of Roll Formed Rain Gutters

Roll formed rain gutters are produced through the following primary steps:

1. Decoiling – Coil of thin metal strip is loaded on a powered decoiler

2. Feeding – Decoiler unwinds the coil to continuously feed the strip

3. Roll forming – Strip passes through a series of roller stations to bend into shape

4. Cutoff – Formed gutter cut to specified length by cutoff device

5. Offloading – Gutters removed manually or by conveyor

6. Post-processing – Additional steps like hole punching

7. Packaging – Finished gutters stacked, bundled, and packed

The automated roll forming process enables high volume production with minimal labor.

How to Choose a Rain Gutter Roll Forming Machine Supplier

Here are important factors to consider when selecting a rain gutter roll former supplier:

Choosing a Rain Gutter Roll Former Supplier

| Factor | विवरण |

|---|---|

| Reputation | Experienced manufacturer with proven reputation |

| Customization | Ability to custom design machine for required gutter profile |

| Build quality | Use of quality materials and robust construction |

| Certification | ISO, CE certified for safety and quality standards |

| Automation | Level of automation like decoiler, conveyors etc. |

| Support | responsive technical support service |

| स्पेयर पार्ट्स | Availability of spare parts and after sales service |

| Cost | Competitive pricing and value for money |

| Lead time | Ability to deliver machine quickly as per schedule |

- Shortlist suppliers based on capabilities, experience, and customer reviews

- Prioritize ISO certified manufacturers for assured quality

- Evaluate design proposals and expected output to match needs

- Ensure adequate local support for smooth maintenance

Selecting the right supplier is crucial to get a properly designed rain gutter roll former for maximum production efficiency.

Pros and Cons of Using Rain Gutter Roll Forming Machines

Advantages of Rain Gutter Roll Forming Machines

- Highly automated for continuous production

- Consistent quality with standardized profiles

- Higher output volumes compared to manual methods

- Minimal manpower required due to automation

- Uniform profile and smooth surface finish

- Flexibility to change dimensions fast

- Lower material wastage than conventional fabrication

- Safer enclosed forming compared to open brakes

- Relatively lower cost for mass gutter production

Limitations of Rain Gutter Roll Forming Machines

- High initial machine purchase cost

- Require skilled personnel for machine operation

- Roller changeover needed for profile adjustments

- Limited flexibility compared to custom fabrication

- Secondary finishing steps may still be required

- Not economical for low to medium volume production

Comparison to Manual Fabrication

| रोल बनाना | Manual Fabrication |

|---|---|

| Automated higher volumes | Slower production rate |

| Lower operational costs | High labor costs |

| Limited flexibility | More customization possible |

| Standardized profiles | Unique profiles can be made |

| Consistent quality | Quality depends on skill |

| Lower material wastage | Comparatively more wastage |

Installation and Operation of Rain Gutter Roll Formers

Proper installation and operation procedures are required to leverage the full potential of a rain gutter roll forming machine and maximize its production output.

Rain Gutter Roll Former Installation

- Clean, level foundation as per loading requirements

- Align machine accurately on foundation

- Tighten all base bolts securely

- Connect electric power supply to control panel

- Installdecoiler and exit conveyors if present

- Lubricate all moving parts prior to start

- Strictly follow manufacturer’s instructions

Rain Gutter Roll Former Operation

- Ensure all safety guards are in place prior to start

- Feed input strip coil on decoiler

- Set forming speed, nip roller pressure on control panel

- Run machine till first gutter is fully formed

- Inspect first piece and adjust roller positions if required

- Allow steady state production and check random samples

- Periodically lubricate drivetrains during operation

- Follow standard operating procedures

Proper installation, safety precautions, and routine maintenance are vital for trouble-free functioning of a rain gutter roll former.

Maintenance of Rain Gutter Roll Forming Machines

Regular preventive maintenance is required to keep a rain gutter roll former in good working condition.

Rain Gutter Roll Former Maintenance

| Activity | Schedule |

|---|---|

| Inspect rollers | Daily |

| Check strip alignment | Daily |

| Test emergency stops | Weekly |

| Lubricate roller bearings | Monthly |

| Inspect electrical wiring | Yearly |

| Adjust drive chain/belt tension | As needed |

| Replace roller bearings | After 10,000 hours |

| Grease linear guides | Quarterly |

| Change hydraulic oil | Yearly or as per hours |

- Follow manufacturer’s maintenance manual

- Keep records of maintenance work

- Replace worn parts like bearings periodically

- Train personnel on proper methods for upkeep

Well maintained machines have longer lifespan and better uptime for maximum productivity.

सामान्य प्रश्न

Q: What materials can be roll formed into gutters?

A: Most commonly galvanized steel and aluminum coils are used. Other materials like copper, stainless steel and titanium can also be formed.

Q: What are the different types of roll formed gutter profiles?

A: K-style, half-round, square, and fascia gutters are popular profiles that are standardized. Custom profiles can also be designed.

Q: How to calculate production rate for rain gutters?

A: Production rate in meters/min is equal to forming speed x number of gutters cut per minute. For example 10 m/min speed with 5 cuts per minute is 10 x 5 = 50 meters of gutter/min.

Q: What thickness of metal coils is required?

A: For most residential rain gutters, thickness between 0.4 mm to 0.7 mm is commonly used. Up to 1.2 mm coils can be run on larger roll formers.

Q: How many roller stations do I need for standard gutter profiles?

A: 15 to 20 stations are typically adequate for standard commercial gutter profiles. More complex or architectural gutters may require 25 to 40 stations.

Q: What are the added features available for rain gutter roll forming lines?

A: Common added features include punching, embossing, online cutting, auto oiling, and gutter packaging solutions. More advanced Industry 4.0 data collection modules are also available.

Q: What should be checked during gutter roll former installation?

A: Level foundation, proper electric supply, tight base bolts, lubrication of moving parts, decoiler and exit conveyor setup, and test runs should all be confirmed per the manufacturer’s instructions before full production.

Q: How much area is needed for a rain gutter roll forming machine?

A: The machine length, rear clearance for decoiler, and gutter offloading space needs to be considered. Typically an area of about 7m x 3m is required for a standard production line with some working space.

निष्कर्ष

Rain gutter roll forming technology provides an efficient automated solution for high volume production of standardized rain gutter profiles. With capabilities to form different designs and integrate additional functions like hole punching or embossing, modern roll formers offer extensive flexibility for gutter fabrication.

Choosing the appropriately designed machine with adequate roller stations, power, and speed is necessary to match intended production requirements and gutter dimensions. Reputed manufacturers can provide customized equipment along with the expertise to set up optimal rain gutter manufacturing lines.

With the increasing adoption of automated roll forming globally, especially by large gutter fabricators, this metalworking process will continue to transform rainwater collection products with improved quality, speed, and cost efficiency.