Apa itu Mesin Roll Forming Roll Forming Rumah Kontainer Ketebalan 3mm Cross Top Beam?

Mesin Roll Forming Roll Forming Rumah Kontainer Ketebalan 3mm lebih dari sekedar peralatan khusus; ini adalah pengubah permainan untuk industri konstruksi. Dengan tepat teknologi pembentukan gulunganmesin ini membuat balok atas silang dengan kekuatan dan daya tahan yang unggul, memastikan struktur yang tahan lama dan andal untuk rumah kontainer dan aplikasi lainnya.

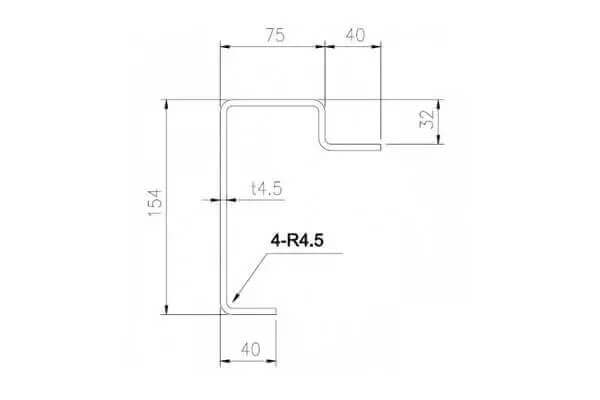

Berbagai komponen mesin bekerja sama untuk menghasilkan bentuk dan ukuran yang tepat dari cross top beam dengan ketebalan 3mm dan lebar hingga 300mm. Decoiler, pemandu pengumpanan, perangkat perataan, sistem pembentukan gulungan, sistem pemotongan hidraulik, dan sistem kontrol semuanya memainkan peran penting dalam menciptakan balok atas silang berkualitas tinggi. Tingkat presisi ini memastikan bahwa balok-balok tersebut saling menyatu dengan mulus dan aman, menjamin stabilitas dan kekuatan struktur.

Mesin Roll Forming Roll Forming Rumah Kontainer Balok Atas Silang Ketebalan 3mm adalah alat penting untuk konstruksi modern, memungkinkan pembangun untuk membuat struktur yang memenuhi tuntutan desain bangunan modern. Keandalan, efisiensi, dan akurasi alat berat ini menjadikannya investasi yang sangat baik untuk bisnis apa pun di industri konstruksi. Dengan peralatan ini, Anda dapat memproduksi balok silang atas yang memenuhi kebutuhan spesifik Andamemastikan bahwa struktur Anda dibangun untuk tahan lama.

Parameter Balok Atas Silang Rumah Kontainer Tebal 3mm Pembentukan Gulungan Mesin

| Tidak. | Barang | Spesifikasi |

| 1 | Decoiler | Decoiler manual 5T |

| 2 | Bahan tempat tidur pabrik | Pengelasan baja 450 H |

| 3 | Jenis platform pemberian makan | Jenis rol samping |

| 4 | Metode transmisi | Penggerak kotak roda gigi |

| 5 | Ketebalan dinding samping | 20mm |

| 6 | Diameter poros | Diameter 95mm dengan poros padat |

| 7 | Daya motor utama | 2 * 18.5kw |

| 8 | Kecepatan mesin | 8-10 m / mnt |

| 9 | Stasiun pembentuk | 20 stasiun |

| 10 | Bahan poros | GCR 15 dengan perlakuan panas |

| 11 | Bahan pisau pemotong | CR 12Mov |

| 12 | Daya stasiun pompa | 5,5kw |

| 13 | Ketebalan bahan baku | 2.5-4.0mm |

| 14 | Akurasi ukuran panjang | +/- 2mm |

| 15 | Cetakan lubang hantaman | Satu set |

Mesin Roll Forming Balok Atas Silang Rumah Kontainer Ketebalan 3mm kami - peralatan yang ideal untuk memproduksi balok atas silang berkualitas tinggi untuk konstruksi rumah kontainer. Dengan fitur-fiturnya yang unggul dan kinerja yang andal, ini adalah investasi yang sempurna untuk bisnis apa pun di industri konstruksi.

Mesin kami menawarkan decoiler Manual 5T, bahan tempat tidur pabrik pengelasan baja 450 H, platform pengumpanan tipe roller samping, dan metode transmisi penggerak gearbox. 20 stasiun dan poros padat berdiameter 95mm yang terbuat dari GCR 15 dengan perlakuan panas memastikan pembentukan yang akurat dan konsisten, sementara daya motor utama 2 * 18.5kw dan daya stasiun pompa 5.5kw memastikan produksi yang efisien dengan kecepatan 8-10m / mnt.

Mesin ini mampu menangani ketebalan bahan baku 2,5-4,0mm dengan akurasi ukuran panjang +/- 2mm. Bahan pisau pemotong CR 12Mov-nya memastikan pemotongan dan pembentukan balok atas silang yang presisi, sementara cetakan lubang pengikat menambahkan tingkat keserbagunaan ekstra pada mesin.

Di Sussman Machinery, kami memproduksi mesin berkualitas tinggi untuk semua jenis bagian kontainer baja strukturaltermasuk kit pintu kontainer pengiriman, panel samping, panel perbaikan atap, engsel pintu, kunci pelintir, dan banyak lagi. Percayakan kepada kami untuk menyediakan lini produksi terbaik dan layanan purna jual yang sangat baik, Investasikan pada Mesin Roll Forming Roll Forming Rumah Kontainer Balok Atas Silang Ketebalan 3mm kami dan bawa bisnis konstruksi rumah kontainer Anda ke level berikutnya. Hubungi kami hari ini untuk mempelajari lebih lanjut.

Bagaimana Cara Kerja Mesin Roll Forming Roll Forming Rumah Kontainer Tebal 3mm?

Itu 3mm Tebal Rumah Kontainer Cross Top Beam Roll Forming Machine bekerja dengan mengambil gulungan baja dan memprosesnya melalui serangkaian langkah untuk membentuk balok atas silang. Berikut ini adalah rincian alur kerja yang terlibat dalam pembuatan balok atas silang menggunakan mesin ini:

- Mengirim Material Kosong: Kumparan baja dimuat ke dalam decoiler dan mesin mengirimkan material kosong ke bagian pengumpanan terpandu.

- Pengumpanan Terpandu: Pemandu pengumpanan membantu memandu kumparan baja melalui mesin untuk memastikan pengumpanan yang konsisten dan akurat.

- Roll Forming: Kumparan baja dilewatkan melalui sistem roll forming, yang membentuknya menjadi profil balok silang yang diinginkan. Sistem roll forming terdiri dari serangkaian rol yang memberikan tekanan dan membengkokkan baja ke bentuk yang dibutuhkan.

- Pemotongan Panjang Tetap: Setelah balok atas silang terbentuk, sistem pemotongan hidraulik memotong balok sesuai panjang yang dibutuhkan. Hal ini memastikan bahwa setiap balok memiliki ukuran yang konsisten dan memenuhi spesifikasi yang diperlukan.

- Papan Produk Jadi: Balok atas silang yang sudah jadi kemudian ditempatkan di atas papan di mana ia dapat diperiksa secara manual untuk mengetahui adanya cacat atau ketidaksempurnaan. Setiap penyesuaian yang diperlukan dapat dilakukan pada tahap ini.

- Operasi PLC: Sistem kontrol alat berat kemudian diakses melalui halaman operasi PLC. Operator memasukkan spesifikasi dan dimensi yang diperlukan dari balok atas silang.

- Pencetakan Otomatis: Setelah pengaturan yang diperlukan dimasukkan, operator menekan tombol "Start" dan mesin secara otomatis mengumpankan gulungan baja melalui sistem roll forming, memotong balok atas silang sesuai panjang yang ditentukan, dan mencetaknya ke dalam bentuk yang diinginkan.

Komponen yang berbeda dari Mesin Roll Forming Roll Forming Balok Atas Rumah Kontainer Ketebalan 3mm bekerja sama dalam proses yang terkoordinasi untuk menghasilkan balok atas silang berkualitas tinggi. Decoiler, pemandu pengumpanan, perangkat perataan, sistem pembentuk gulungan, sistem pemotongan hidraulik, dan sistem kontrol adalah komponen penting dari alat berat yang bekerja serempak untuk memastikan produksi yang efisien dan akurat. Penggunaan diagram dan gambar dapat membantu mengilustrasikan proses dan membuatnya lebih mudah dipahami.

Fitur dan Manfaat dari Mesin Roll Forming Roll Forming Rumah Kontainer Balok Atas Silang Ketebalan 3mm

Mesin Roll Forming Roll Forming Rumah Kontainer Ketebalan 3mm hadir dengan berbagai fitur dan manfaat yang menjadikannya mesin yang andal dan alat yang efisien untuk industri konstruksi. Berikut ini beberapa fitur dan manfaat utama:

- Daya tahan: Mesin ini dibuat dengan menggunakan bahan dan komponen berkualitas tinggi, memastikan bahwa mesin ini dapat bertahan dalam penggunaan berat dan bertahan untuk waktu yang lama.

- Presisi: Mesin ini dirancang untuk membuat balok atas silang dengan tingkat presisi dan akurasi yang tinggi, memastikan bahwa balok tersebut memenuhi spesifikasi yang diperlukan.

- Efisiensi: Mesin ini beroperasi pada kecepatan tinggi, sehingga memungkinkan produksi balok atas silang yang cepat, yang membantu meningkatkan produktivitas dan mengurangi biaya.

- Mudah Digunakan: Mesin ini dirancang dengan kontrol yang mudah digunakansehingga mudah dioperasikan dan disesuaikan.

- Perawatan yang rendah: Alat berat ini memerlukan perawatan minimal, sehingga membantu mengurangi waktu henti dan biaya perawatan.

- Keserbagunaan: Mesin ini dapat digunakan untuk membuat balok atas silang dengan lebar dan ketebalan yang berbeda, sehingga menjadikannya alat serbaguna untuk berbagai proyek konstruksi.

- Hemat biaya: Mesin ini adalah alat yang hemat biaya untuk produksi balok atas silang, membantu mengurangi biaya produksi dan meningkatkan profitabilitas.

Secara keseluruhan, Mesin Roll Forming Roll Forming Balok Atas Silang Rumah Kontainer Ketebalan 3mm adalah alat yang andal dan efisien yang dapat membantu perusahaan konstruksi merampingkan proses produksi mereka dan menghasilkan balok atas silang berkualitas tinggi untuk berbagai proyek.

Penerapan Mesin Roll Forming Roll Forming Rumah Kontainer Balok Atas Silang Ketebalan 3mm

Mesin Roll Forming Roll Forming Rumah Kontainer Ketebalan 3mm memiliki berbagai macam aplikasi dalam industri konstruksi. Salah satu penggunaan utama mesin ini adalah dalam pembuatan balok silang untuk rumah kontainer. Rumah kontainer adalah solusi perumahan yang inovatif dan berkelanjutan yang semakin populer di seluruh dunia. Struktur ini terbuat dari kontainer pengiriman yang telah diubah menjadi rumah, kantor, dan jenis bangunan lainnya. Balok atas silang adalah komponen penting dari rumah kontainer sebagai memberikan dukungan struktural dan stabilitas.

Mesin Roll Forming Balok Atas Silang Rumah Kontainer Ketebalan 3mm juga digunakan untuk membuat balok atas silang untuk jenis struktur lain, seperti bangunan prefabrikasi, struktur baja, dan jenis konstruksi modular lainnya. Struktur ini menjadi semakin populer karena keefektifan biaya, kecepatan konstruksi, dan kemudahan perakitannya.

Selain untuk industri konstruksi, Mesin Roll Forming Cross Top Beam Rumah Kontainer Ketebalan 3mm juga dapat digunakan pada industri lain yang membutuhkan produksi komponen logam berbentuk presisi. Ini termasuk industri seperti otomotif, dirgantara, dan manufaktur.

Secara keseluruhan, Mesin Roll Forming Roll Forming Balok Atas Silang Rumah Kontainer Ketebalan 3mm adalah peralatan serbaguna yang memiliki berbagai macam aplikasi di berbagai industri. Kemampuannya untuk menghasilkan balok silang berkualitas tinggi dengan tingkat akurasi dan efisiensi yang tinggi menjadikannya alat yang sangat diperlukan untuk proses konstruksi dan manufaktur modern.

apa itu mesin pembuat gulungan balok kotak?

Mesin pembuat gulungan balok kotak adalah jenis peralatan industri yang digunakan dalam proses fabrikasi dan manufaktur logam. Ini dirancang khusus untuk menghasilkan balok kotak, yang merupakan anggota struktural berongga dengan penampang persegi panjang atau persegi. Balok ini biasanya digunakan dalam konstruksi, infrastruktur, dan berbagai aplikasi lain yang membutuhkan kekuatan dan daya dukung beban.

Mesin pembuat gulungan balok kotak menggunakan proses pembentukan gulungan untuk membentuk strip atau gulungan logam kontinu menjadi balok kotak. Mesin ini terdiri dari serangkaian rol atau stasiun gulungan yang disusun secara berurutan. Setiap rol memberikan tekanan pada strip logam, secara bertahap menekuk dan membentuknya menjadi bentuk yang diinginkan. Rol biasanya dapat disesuaikan untuk mengakomodasi ukuran dan profil balok yang berbeda.

Proses pembentukan gulungan bersifat kontinu, yang berarti strip logam melewati mesin secara terus menerus. Saat strip bergerak melalui setiap stasiun gulungan, strip mengalami pembengkokan dan pembentukan tambahan hingga mencapai bentuk akhir balok kotak. Mesin dapat menggabungkan stasiun tambahan untuk tugas-tugas seperti melubangi lubang, memotong sesuai panjang, atau menambahkan fitur khusus pada balok.

Mesin pembuat balok kotak menawarkan beberapa keunggulan dalam hal efisiensi dan presisi. Mesin ini dapat memproduksi balok kotak dengan kecepatan tinggi, sehingga cocok untuk produksi skala besar. Prosesnya memastikan dimensi yang konsisten dan akurat, menghasilkan balok yang seragam dengan toleransi yang ketat. Selain itu, mesin ini dapat menangani berbagai material, termasuk baja, aluminium, dan logam lain yang biasa digunakan dalam konstruksi.

Secara keseluruhan, mesin roll forming box beam memainkan peran penting dalam industri manufaktur dengan memberikan solusi yang hemat biaya dan efisien untuk memproduksi box beam dengan kualitas dan integritas struktural yang konsisten.

aplikasi mesin pembuat gulungan pagar pembatas balok w

- Hambatan Keselamatan Jalan: Aplikasi utama dari mesin pembuat gulungan pagar pembatas balok W adalah produksi pagar pembatas yang digunakan sebagai penghalang keselamatan jalan. Pembatas ini dipasang di sepanjang jalan raya, jalan tol, dan jalan lainnya untuk mencegah kendaraan menyeberang ke lalu lintas yang berlawanan atau meninggalkan jalan. Pagar pembatas balok-W efektif dalam mengarahkan kendaraan yang menyimpang dan menyerap energi tumbukan, sehingga mengurangi tingkat keparahan kecelakaan.

- Jalan Raya dan Jalan Tol: Pagar pembatas balok W umumnya ditemukan di jalan raya dan jalan tol untuk meningkatkan keselamatan jalan. Pagar pembatas ini ditempatkan secara strategis di area yang rawan kecelakaan, seperti tikungan, persimpangan, jembatan, dan median. Pagar pembatas memberikan penghalang pelindung antara jalur lalu lintas yang berlawanan, mengurangi risiko tabrakan langsung dan meminimalkan kemungkinan kendaraan keluar dari jalan dan menabrak rintangan.

- Gerbang Tol dan Plaza: Pagar pembatas W-beam sering digunakan di area pintu tol dan plaza untuk memandu lalu lintas dan memberikan penghalang fisik antara kendaraan dan loket pengumpulan tol. Pagar ini membantu menjaga arus lalu lintas dan memastikan keselamatan petugas pintu tol dan pengendara.

- Tempat Parkir dan Area Industri: Pagar pembatas balok-W juga digunakan di tempat parkir, area industri, dan lokasi lain di mana lalu lintas kendaraan perlu dipisahkan dari pejalan kaki atau bangunan yang dilindungi. Pagar ini menciptakan batas yang jelas dan mencegah akses yang tidak sah ke area terlarang.

- Perlindungan Jembatan dan Jalan Layang: Pagar pembatas yang diproduksi oleh mesin pembuat gulungan pagar pembatas balok W digunakan untuk melindungi jembatan, jalan layang, dan struktur layang lainnya. Pagar pembatas bertindak sebagai penghalang keamanan, mencegah kendaraan bertabrakan dengan tepi atau jatuh dari struktur jika terjadi kecelakaan.

- Pembatas Median: Dalam kasus jalan raya yang terbagi, pagar pembatas balok-W dapat dipasang sebagai pembatas median untuk memisahkan lalu lintas yang berlawanan dan mengurangi risiko kecelakaan persilangan.

5 produsen mesin las berkas elektron teratas

- Sussman Machinery (Wuxi) Co, Ltd mengkhususkan diri dalam pembuatan mesin pembuat gulungan dingin baja bentuk sekitar 20 tahun, mengekspor garis menggorok dan bisnis perdagangan internasional seluruh kelompok Kami mengekspor ke lebih dari 100 negara, dan pelanggan kami ada di seluruh dunia, terutama Australia, Amerika Selatan, Eropa, Eropa, India, Timur Tengah, Eropa Utara, dan Afrika Utara. Selain itu, kami ingin membangun mesin terbaik untuk pelanggan, nilai-nilai inti kami adalah "Kualitas, Efisiensi, Kredibilitas & Integritas", yang dapat dengan kuat dan solid mendukung kami untuk melangkah lebih jauh.

- Sciaky Inc (AS): Sciaky adalah produsen terkemuka sistem pengelasan berkas elektron canggih dan menyediakan solusi untuk berbagai industri termasuk kedirgantaraan, pertahanan, otomotif, dan banyak lagi. Mereka menawarkan mesin las berkas elektron standar dan khusus dengan presisi dan keandalan yang tinggi.

- PVA TePla AG (Jerman): PVA TePla mengkhususkan diri dalam pengembangan dan produksi sistem pengelasan berkas elektron untuk berbagai aplikasi. Mesin mereka dikenal dengan teknologi canggih, kemampuan pengelasan presisi, dan hasil berkualitas tinggi. Mereka melayani industri seperti otomotif, kedirgantaraan, medis, dan energi.

- Carl Zeiss AG (Jerman): Carl Zeiss adalah produsen sistem optik yang terkenal dan memiliki divisi yang memproduksi mesin las berkas elektron. Mereka menawarkan sistem pengelasan berkas elektron berkinerja tinggi dengan fitur-fitur canggih, termasuk pemantauan dan kontrol proses, untuk memastikan proses pengelasan yang akurat dan efisien.

- Electron Beam Engineering (AS): Electron Beam Engineering adalah produsen dan penyedia layanan mesin las berkas elektron terkemuka. Mereka menawarkan berbagai sistem pengelasan berkas elektron, termasuk solusi yang dirancang khusus, dan memberikan dukungan dan layanan yang komprehensif kepada pelanggan mereka.

Ulasan

Belum ada ulasan.