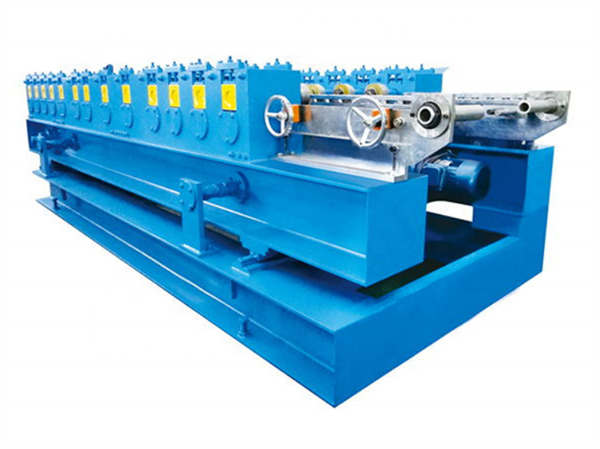

¿Qué es la máquina perfiladora de vigas transversales de 3mm de espesor?

La máquina perfiladora de vigas transversales de 3 mm de grosor para casas contenedoras es más que un equipo especializado: cambia las reglas del juego de la industria de la construcción. Con una precisión tecnología de perfiladoEsta máquina crea vigas transversales con una resistencia y durabilidad superiores, garantizando estructuras duraderas y fiables para casas contenedor y otras aplicaciones.

Los diversos componentes de la máquina trabajan conjuntamente para producir formas y tamaños precisos de vigas transversales con un grosor de 3 mm y una anchura de hasta 300 mm. El desenrollador, la guía de alimentación, el dispositivo de nivelación, el sistema de perfilado, el sistema de corte hidráulico y el sistema de control desempeñan un papel fundamental en la creación de vigas transversales de alta calidad. Este nivel de precisión asegura que las vigas encajen a la perfección y de forma segura, garantizando la estabilidad y resistencia de la estructura.

La máquina perfiladora de vigas transversales de 3 mm de grosor para casas contenedoras es una herramienta esencial para la construcción moderna, ya que permite a los constructores crear estructuras que satisfacen las exigencias del diseño de edificios modernos. La fiabilidad, eficiencia y precisión de la máquina la convierten en una excelente inversión para cualquier empresa del sector de la construcción. Con este equipo, puede fabricar vigas transversales que respondan a sus necesidades específicasgarantizando que sus estructuras se construyan para durar.

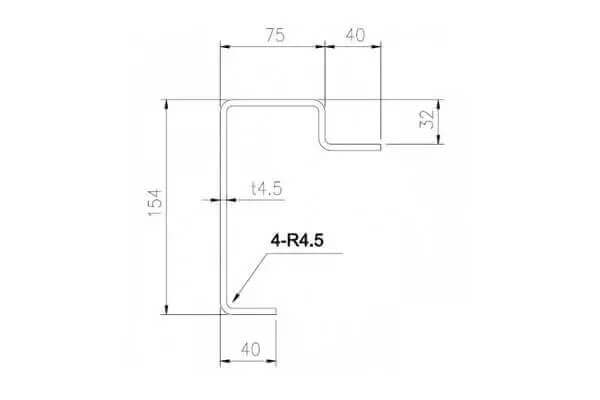

Parámetros de la viga superior transversal de 3 mm de grosor para casas contenedoras Perfilado Máquina

| No. | Artículo | Especificación |

| 1 | desbobinador | 5T Desenrollador manual |

| 2 | Material del lecho del molino | Soldadura de acero 450 H |

| 3 | Tipo de plataforma de alimentación | Tipo rodillo lateral |

| 4 | Método de transmisión | Accionamiento de caja de cambios |

| 5 | Grosor de la pared lateral | 20 mm |

| 6 | Diámetro del eje | 95 mm de diámetro con eje macizo |

| 7 | Potencia del motor principal | 2*18,5kw |

| 8 | Velocidad de la máquina | 8-10 m/min |

| 9 | Estaciones de conformado | 20 estaciones |

| 10 | Material del eje | GCR 15 con tratamiento térmico |

| 11 | Material de la cuchilla de corte | CR 12Mov |

| 12 | Potencia de la estación de bombeo | 5,5 kilovatios |

| 13 | Materia prima Grosor | 2,5-4,0 mm |

| 14 | Precisión en el calibrado de longitudes | +/- 2 mm |

| 15 | Molde con orificio para cordón | Un juego |

Nuestra Máquina Perfiladora de Viga Superior Cruzada para Casa Contenedor de 3mm de Espesor - es el equipo ideal para producir vigas superiores cruzadas de alta calidad para la construcción de casas contenedor. Con sus características superiores y funcionamiento confiable, es la inversión perfecta para cualquier empresa del sector de la construcción.

Nuestra máquina cuenta con un desbobinador manual de 5T, lecho de acero para soldadura de 450 H, plataforma de alimentación tipo rodillo lateral y método de transmisión por caja de engranajes. Sus 20 estaciones y eje sólido de 95mm de diámetro hecho de GCR 15 con tratamiento térmico aseguran un formado preciso y consistente, mientras que la potencia de su motor principal de 2*18.5kw y la potencia de la estación de bombeo de 5.5kw aseguran una producción eficiente a una velocidad de 8-10m/min.

Esta máquina es capaz de manejar espesores de materia prima de 2,5-4,0 mm con una precisión de dimensionamiento longitudinal de +/- 2 mm. Su material de cuchilla de corte CR 12Mov garantiza un corte y una conformación precisos de las vigas superiores transversales, mientras que el molde de orificio de cordón añade un nivel adicional de versatilidad a la máquina.

En Sussman Machinery producir máquinas de alta calidad para todo tipo de piezas estructurales de acero para contenedoresLa línea de producción de casas contenedoras de 3mm de espesor, incluye kit de puerta de hombre contenedor, paneles laterales, paneles de reparación de techo, bisagras de puerta, cerraduras giratorias, y más. Invierta en nuestra maquina perfiladora de viga transversal superior para casa container de 3mm de espesor y lleve su negocio de construcción de casa container al siguiente nivel. Contáctenos hoy para saber más.

¿Cómo funciona la máquina formadora de rollos de viga transversal superior de 3mm de espesor?

los máquina formadora de rollos de viga superior cruzada para casa contenedor de 3 mm de espesor funciona tomando bobinas de acero y procesándolas a través de una serie de pasos para formar una viga transversal. A continuación se desglosa el flujo de trabajo necesario para crear una viga transversal con esta máquina:

- Envío del material en bruto: La bobina de acero se carga en el desenrollador y la máquina envía el material en bruto a la sección de alimentación guiada.

- Alimentación guiada: La guía de alimentación ayuda a guiar la bobina de acero a través de la máquina para garantizar una alimentación uniforme y precisa.

- Perfilado: La bobina de acero pasa por el sistema de perfilado, que le da la forma deseada. El sistema de perfilado consta de una serie de rodillos que aplican presión y doblan el acero para darle la forma deseada.

- Corte de longitud fija: Una vez formada la viga transversal, el sistema de corte hidráulico corta la viga a la longitud requerida. Esto garantiza que cada viga tenga un tamaño uniforme y cumpla las especificaciones requeridas.

- Tablero de producto acabado: La viga transversal acabada se coloca en un tablero donde puede inspeccionarse manualmente para detectar cualquier defecto o imperfección. En esta fase pueden realizarse los ajustes necesarios.

- Funcionamiento del PLC: Se accede al sistema de control de la máquina a través de la página de funcionamiento del PLC. El operario introduce las especificaciones y dimensiones necesarias de la viga superior transversal.

- Moldeo automático: Una vez introducidos los ajustes necesarios, el operario pulsa el botón "Start" y la máquina alimenta automáticamente la bobina de acero a través del sistema de perfilado, corta la viga superior transversal a la longitud especificada y la moldea con la forma deseada.

Los diferentes componentes de la maquina perfiladora de vigas transversales de 3mm de espesor trabajan juntos en un proceso coordinado para producir vigas transversales de alta calidad. El desenrollador, la guía de alimentación, el dispositivo de nivelación, el sistema de perfilado, el sistema de corte hidráulico y el sistema de control son componentes críticos de la máquina que trabajan al unísono para garantizar una producción eficiente y precisa. El uso de diagramas e imágenes puede ayudar a ilustrar el proceso y facilitar su comprensión.

Características y beneficios de la máquina formadora de rollos de vigas transversales superiores para casas contenedoras de 3mm de espesor

La máquina perfiladora de vigas transversales superiores para casas contenedoras de 3 mm de espesor viene con una serie de características y beneficios que la convierten en una máquina confiable y herramienta eficaz para el sector de la construcción. Estas son algunas de sus principales características y ventajas:

- Durabilidad: La máquina está construida con materiales y componentes de alta calidad, lo que garantiza que pueda soportar los rigores del uso intensivo y durar mucho tiempo.

- Precisión: La máquina está diseñada para crear vigas transversales superiores con un alto grado de precisión y exactitud, garantizando que cumplan las especificaciones requeridas.

- Eficacia: La máquina funciona a gran velocidad, lo que permite producir rápidamente vigas transversales superiores, lo que contribuye a mejorar la productividad y reducir los costes.

- Fácil de usar: La máquina es diseñado con controles fáciles de usarEl sistema de regulación de la velocidad es muy sencillo de manejar y ajustar.

- Bajo mantenimiento: La máquina requiere un mantenimiento mínimo, lo que ayuda a reducir el tiempo de inactividad y los costes de mantenimiento.

- Versatilidad: La máquina puede utilizarse para crear vigas transversales superiores con diferentes anchuras y grosores, lo que la convierte en una herramienta versátil para una amplia gama de proyectos de construcción.

- Rentable: La máquina es una herramienta rentable para la producción de vigas transversales, lo que ayuda a reducir los costes de producción y mejorar la rentabilidad.

En general, la Máquina Perfiladora de Vigas Transversales de 3mm de Espesor es una herramienta fiable y eficiente que puede ayudar a las empresas de construcción a racionalizar sus procesos de producción y producir vigas transversales de alta calidad para una serie de proyectos.

Aplicación de la Máquina Perfiladora de Vigas Cruzadas de 3mm de Espesor para Casas de Contenedores

La máquina formadora de rollos de viga superior transversal de casa de contenedor de 3 mm de espesor tiene una amplia gama de aplicaciones en el sector de la construcción. Uno de los principales usos de esta máquina es la fabricación de vigas superiores transversales para casas contenedor. Las casas contenedor son una solución de vivienda innovadora y sostenible que está ganando popularidad en todo el mundo. Estas estructuras se fabrican a partir de contenedores de transporte que se han reconvertido en viviendas, oficinas y otros tipos de edificios. La viga superior transversal es un componente esencial de la casa contenedor, ya que proporciona apoyo estructural y estabilidad.

La máquina perfiladora de vigas transversales de 3 mm de grosor para casas contenedoras también se utiliza para fabricar vigas transversales para otros tipos de estructuras, como edificios prefabricados, estructuras de acero y otros tipos de construcción modular. Estas estructuras son cada vez más populares debido a su rentabilidad, velocidad de construcción y facilidad de montaje.

Además de la industria de la construcción, la máquina perfiladora de vigas transversales superiores para casas contenedoras de 3 mm de espesor también se puede utilizar en otras industrias que requieren la producción de componentes metálicos con formas de precisión. Esto incluye industrias como la automotriz, aeroespacial y manufacturera.

En general, la maquina perfiladora de vigas transversales de 3mm de espesor es un equipo versátil que tiene una amplia gama de aplicaciones en diversas industrias. Su capacidad para producir vigas transversales de alta calidad con un alto grado de precisión y eficiencia la convierte en una herramienta indispensable para los procesos modernos de construcción y fabricación.

¿qué es la perfiladora de vigas cajón?

Una perfiladora de vigas cajón es un tipo de equipo industrial utilizado en los procesos de fabricación y manufactura de metales. Está diseñado específicamente para producir vigas cajón, que son miembros estructurales huecos con una sección transversal rectangular o cuadrada. Estas vigas se utilizan habitualmente en construcción, infraestructuras y otras aplicaciones en las que la resistencia y la capacidad de carga son esenciales.

La perfiladora de vigas cajón utiliza un proceso de perfilado para dar forma de vigas cajón a tiras o bobinas continuas de metal. La máquina consta de una serie de rodillos o estaciones de rodillos dispuestos en una secuencia. Cada rodillo aplica presión a la tira de metal, doblándola gradualmente y dándole la forma deseada. Los rodillos suelen ser ajustables para adaptarse a diferentes tamaños y perfiles de vigas.

El proceso de perfilado es continuo, lo que significa que la banda metálica pasa por la máquina de forma continua. A medida que el fleje pasa por cada estación de laminado, se va doblando y moldeando hasta alcanzar la forma final de una viga de caja. La máquina puede incorporar estaciones adicionales para tareas como perforar agujeros, cortar a medida o añadir características específicas a la viga.

Las perfiladoras de vigas cajón ofrecen varias ventajas en términos de eficacia y precisión. Pueden producir vigas cajón a gran velocidad, lo que las hace adecuadas para la producción a gran escala. El proceso garantiza dimensiones uniformes y precisas, lo que da como resultado vigas uniformes con tolerancias estrechas. Además, las máquinas pueden trabajar con diversos materiales, como acero, aluminio y otros metales de uso común en la construcción.

En general, las perfiladoras de vigas cajón desempeñan un papel crucial en la industria manufacturera al proporcionar una solución rentable y eficaz para producir vigas cajón con una calidad e integridad estructural constantes.

aplicación de la máquina perfiladora de barandilla de viga w

- Barreras de seguridad vial: La principal aplicación de la máquina perfiladora de barandilla de viga W es la producción de barandillas utilizadas como barreras de seguridad vial. Estas barreras se instalan a lo largo de autopistas, autovías y otras carreteras para evitar que los vehículos se crucen con el tráfico contrario o salgan de la carretera. Las barandillas de viga W son eficaces para redirigir los vehículos errantes y absorber la energía del impacto, reduciendo así la gravedad de los accidentes.

- Autopistas y autovías: Las barandillas de vigas en W se encuentran habitualmente en autopistas y autovías para mejorar la seguridad vial. Se colocan estratégicamente en zonas propensas a accidentes, como curvas, intersecciones, puentes y medianas. Los guardarraíles proporcionan una barrera protectora entre los carriles de tráfico opuestos, reduciendo el riesgo de colisiones frontales y minimizando las posibilidades de que los vehículos se salgan de la carretera y choquen contra obstáculos.

- Cabinas de peaje y plazas: Las barandillas de viga W se utilizan a menudo en áreas de peaje y plazas para guiar el tráfico y proporcionar una barrera física entre los vehículos y las cabinas de cobro de peaje. Ayudan a mantener la fluidez del tráfico y garantizan la seguridad del personal de las cabinas de peaje y de los automovilistas.

- Aparcamientos y zonas industriales: Las barandillas de viga W también se utilizan en aparcamientos, zonas industriales y otros lugares en los que es necesario separar el tráfico de vehículos de los peatones o de estructuras protegidas. Crean un límite claro e impiden el acceso no autorizado a zonas restringidas.

- Protección de puentes y pasos elevados: Las barandillas producidas por la máquina perfiladora de barandillas de viga W se emplean para proteger puentes, pasos elevados y otras estructuras elevadas. Actúan como barrera de seguridad, evitando que los vehículos colisionen con los bordes o caigan de la estructura en caso de accidente.

- Barreras medianas: En el caso de autopistas divididas, se pueden instalar barandillas de vigas en W como barreras medianas para separar el tráfico contrario y reducir el riesgo de accidentes por cruce.

top 5 fabricantes de máquinas de soldadura por haz de electrones

- Sussman Machinery(Wuxi)Co., Ltd. se especializa en la fabricación de máquinas de perfilado de acero en frío alrededor de 20 años, la exportación de la línea de corte longitudinal y todo el grupo de comercio internacional business.we exportar a más de 100 países, y nuestros clientes están en todo el mundo, especialmente Australia, América del Sur, Europa, India, Oriente Medio, Europa del Norte y África del Norte. Además, deseamos construir la mejor máquina para los clientes, nuestros valores fundamentales son "Calidad, Eficiencia, Credibilidad e Integridad", que pueden apoyarnos firme y sólidamente para llegar lejos.

- Sciaky Inc. (EE.UU.): Sciaky es uno de los principales fabricantes de sistemas avanzados de soldadura por haz de electrones y ofrece soluciones para una amplia gama de sectores, como el aeroespacial, el de defensa y el de automoción, entre otros. Ofrecen máquinas de soldadura por haz de electrones estándar y personalizadas de gran precisión y fiabilidad.

- PVA TePla AG (Alemania): PVA TePla está especializada en el desarrollo y la producción de sistemas de soldadura por haz de electrones para diversas aplicaciones. Sus máquinas son conocidas por su avanzada tecnología, su capacidad de soldadura de precisión y sus resultados de alta calidad. Prestan servicio a industrias como la automovilística, aeroespacial, médica y energética.

- Carl Zeiss AG (Alemania): Carl Zeiss es un renombrado fabricante de sistemas ópticos y tiene una división que produce máquinas de soldadura por haz de electrones. Ofrecen sistemas de soldadura por haz de electrones de alto rendimiento con funciones avanzadas, como la supervisión y el control de procesos, para garantizar procesos de soldadura precisos y eficientes.

- Electron Beam Engineering (EE.UU.): Electron Beam Engineering es uno de los principales fabricantes y proveedores de servicios de máquinas de soldadura por haz de electrones. Ofrecen una amplia gama de sistemas de soldadura por haz de electrones, incluidas soluciones diseñadas a medida, y prestan asistencia y servicios integrales a sus clientes.

Valoraciones

No hay valoraciones aún.