What is 3mm Thickness Container House Cross Top Beam Roll Forming Machine?

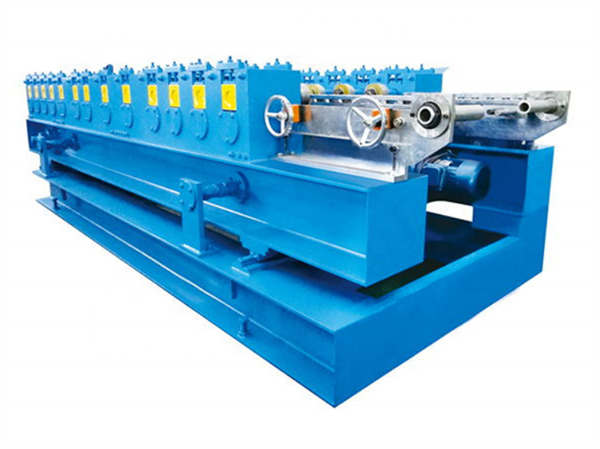

The 3mm Thickness Container House Cross Top Beam Roll Forming Machine is more than just a specialized piece of equipment; it’s a game-changer for the construction industry. With precise roll forming technology, this machine creates cross top beams with superior strength and durability, ensuring long-lasting and reliable structures for container houses and other applications.

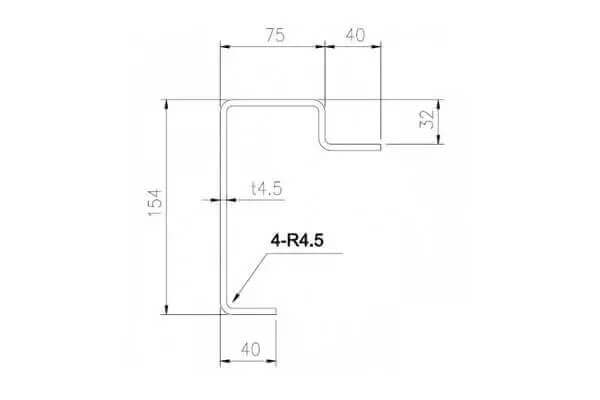

The machine’s various components work together to produce precise shapes and sizes of cross top beams with a thickness of 3mm and a width of up to 300mm. The decoiler, feeding guide, leveling device, roll forming system, hydraulic cutting system, and control system all play critical roles in creating high-quality cross top beams. This level of precision ensures that the beams fit together seamlessly and securely, guaranteeing the stability and strength of the structure.

The 3mm Thickness Container House Cross Top Beam Roll Forming Machine is an essential tool for modern construction, allowing builders to create structures that meet the demands of modern building design. The machine’s reliability, efficiency, and accuracy make it an excellent investment for any business in the construction industry. With this equipment, you can produce cross top beams that meet your specific needs, ensuring that your structures are built to last.

Parameter of 3mm Thickness Container House Cross Top Beam Roll Forming Machine

| No. | Item | Specification |

| 1 | Decoiler | 5T Manual decoiler |

| 2 | Mill bed material | 450 H steel welding |

| 3 | Feeding platform type | Side roller type |

| 4 | Transmission method | Gearbox drive |

| 5 | Side wall thickness | 20mm |

| 6 | Shaft diameter | 95mm diameter with solid shaft |

| 7 | Main motor power | 2*18.5kw |

| 8 | Machine speed | 8-10m/min |

| 9 | Forming stations | 20 stations |

| 10 | Shaft material | GCR 15 with heat treatment |

| 11 | Cutting blade material | CR 12Mov |

| 12 | Pump station power | 5.5 kw |

| 13 | Raw material Thickness | 2.5-4.0mm |

| 14 | Length sizing accuracy | +/- 2mm |

| 15 | Lacing hole mold | One set |

Our 3mm Thickness Container House Cross Top Beam Roll Forming Machine – the ideal equipment for producing high-quality cross top beams for container house construction. With its superior features and reliable performance, it’s the perfect investment for any business in the construction industry.

Our machine boasts a 5T Manual decoiler, 450 H steel welding mill bed material, side roller type feeding platform, and gearbox drive transmission method. Its 20 stations and 95mm diameter solid shaft made of GCR 15 with heat treatment ensure accurate and consistent forming, while its 2*18.5kw main motor power and 5.5kw pump station power ensure efficient production at a speed of 8-10m/min.

This machine is capable of handling raw material thicknesses of 2.5-4.0mm with a length sizing accuracy of +/- 2mm. Its CR 12Mov cutting blade material ensures precise cutting and shaping of the cross top beams, while the lacing hole mold adds an extra level of versatility to the machine.

At Sussman Machinery, we produce high-quality machines for all kinds of structural steel container parts, including shipping container man door kit, side panels, roof repair panels, door hinges, twist locks, and more. Trust us to provide you with the best production line and excellent after-sales service.Invest in our 3mm Thickness Container House Cross Top Beam Roll Forming Machine and take your container house construction business to the next level. Contact us today to learn more.

How the 3mm Thickness Container House Cross Top Beam Roll Forming Machine Works?

The 3mm Thickness Container House Cross Top Beam Roll Forming Machine works by taking steel coils and processing them through a series of steps to form a cross top beam. The following is a breakdown of the workflow involved in creating a cross top beam using this machine:

- Sending Blank Material: The steel coil is loaded onto the decoiler and the machine sends the blank material to the guided feeding section.

- Guided Feeding: The feeding guide assists in guiding the steel coil through the machine to ensure a consistent and accurate feed.

- Roll Forming: The steel coil is passed through the roll forming system, which shapes it into the desired cross top beam profile. The roll forming system consists of a series of rollers that apply pressure and bend the steel to the required shape.

- Fixed Length Cutting: Once the cross top beam has been formed, the hydraulic cutting system cuts the beam to the required length. This ensures that each beam is of a consistent size and meets the required specifications.

- Finished Product Board: The finished cross top beam is then placed on a board where it can be manually inspected for any defects or imperfections. Any necessary adjustments can be made at this stage.

- PLC Operation: The control system of the machine is then accessed through the PLC operation page. The operator inputs the required specifications and dimensions of the cross top beam.

- Automatic Molding: Once the required settings have been entered, the operator presses the “Start” button and the machine automatically feeds the steel coil through the roll forming system, cuts the cross top beam to the specified length, and molds it into the desired shape.

The different components of the 3mm Thickness Container House Cross Top Beam Roll Forming Machine work together in a coordinated process to produce high-quality cross top beams. The decoiler, feeding guide, leveling device, roll forming system, hydraulic cutting system, and control system are all critical components of the machine that work in unison to ensure efficient and accurate production. The use of diagrams and images can help to illustrate the process and make it easier to understand.

Features and Benefits of the 3mm Thickness Container House Cross Top Beam Roll Forming Machine

The 3mm Thickness Container House Cross Top Beam Roll Forming Machine comes with a range of features and benefits that make it a reliable and efficient tool for the construction industry. Here are some of the key features and benefits:

- Durability: The machine is built using high-quality materials and components, ensuring that it can withstand the rigors of heavy use and last for a long time.

- Precision: The machine is designed to create cross top beams with a high degree of precision and accuracy, ensuring that they meet the required specifications.

- Efficiency: The machine operates at a high speed, allowing for the rapid production of cross top beams, which helps to improve productivity and reduce costs.

- Easy to Use: The machine is designed with user-friendly controls, making it easy to operate and adjust.

- Low Maintenance: The machine requires minimal maintenance, helping to reduce downtime and maintenance costs.

- Versatility: The machine can be used to create cross top beams with different widths and thicknesses, making it a versatile tool for a range of construction projects.

- Cost-effective: The machine is a cost-effective tool for the production of cross top beams, helping to reduce production costs and improve profitability.

Overall, the 3mm Thickness Container House Cross Top Beam Roll Forming Machine is a reliable and efficient tool that can help construction companies to streamline their production processes and produce high-quality cross top beams for a range of projects.

Application of the 3mm Thickness Container House Cross Top Beam Roll Forming Machine

The 3mm Thickness Container House Cross Top Beam Roll Forming Machine has a wide range of applications in the construction industry. One of the primary uses of this machine is in the manufacturing of cross top beams for container houses. Container houses are an innovative and sustainable housing solution that are gaining popularity around the world. These structures are made from shipping containers that have been repurposed into homes, offices, and other types of buildings. The cross top beam is an essential component of the container house as it provides structural support and stability.

The 3mm Thickness Container House Cross Top Beam Roll Forming Machine is also used to manufacture cross top beams for other types of structures, such as prefabricated buildings, steel structures, and other types of modular construction. These structures are becoming increasingly popular due to their cost-effectiveness, speed of construction, and ease of assembly.

In addition to the construction industry, the 3mm Thickness Container House Cross Top Beam Roll Forming Machine can also be used in other industries that require the production of precision-shaped metal components. This includes industries such as automotive, aerospace, and manufacturing.

Overall, the 3mm Thickness Container House Cross Top Beam Roll Forming Machine is a versatile piece of equipment that has a wide range of applications in various industries. Its ability to produce high-quality cross top beams with a high degree of accuracy and efficiency makes it an indispensable tool for modern construction and manufacturing processes.

what is box beam roll forming machine?

A box beam roll forming machine is a type of industrial equipment used in metal fabrication and manufacturing processes. It is specifically designed to produce box beams, which are hollow structural members with a rectangular or square cross-section. These beams are commonly used in construction, infrastructure, and various other applications where strength and load-bearing capacity are essential.

The box beam roll forming machine utilizes a roll forming process to shape continuous metal strips or coils into box beams. The machine consists of a series of rollers or roll stations arranged in a sequence. Each roller applies pressure to the metal strip, gradually bending and forming it into the desired shape. The rollers are typically adjustable to accommodate different beam sizes and profiles.

The roll forming process is continuous, meaning that the metal strip passes through the machine in a continuous manner. As the strip moves through each roll station, it undergoes incremental bending and shaping until it reaches the final shape of a box beam. The machine may incorporate additional stations for tasks such as punching holes, cutting to length, or adding specific features to the beam.

Box beam roll forming machines offer several advantages in terms of efficiency and precision. They can produce box beams at high speeds, making them suitable for large-scale production. The process ensures consistent and accurate dimensions, resulting in uniform beams with tight tolerances. Additionally, the machines can handle various materials, including steel, aluminum, and other metals commonly used in construction.

Overall, box beam roll forming machines play a crucial role in the manufacturing industry by providing a cost-effective and efficient solution for producing box beams with consistent quality and structural integrity.

application of w beam guardrail roll forming machine

- Road Safety Barriers: The primary application of the W-beam guardrail roll forming machine is the production of guardrails used as road safety barriers. These barriers are installed alongside highways, expressways, and other roads to prevent vehicles from crossing over into opposing traffic or leaving the road. The W-beam guardrails are effective in redirecting errant vehicles and absorbing impact energy, thereby reducing the severity of accidents.

- Highways and Expressways: W-beam guardrails are commonly found on highways and expressways to enhance road safety. They are strategically placed in areas prone to accidents, such as curves, intersections, bridges, and medians. The guardrails provide a protective barrier between opposing traffic lanes, reducing the risk of head-on collisions and minimizing the chances of vehicles leaving the road and hitting obstacles.

- Toll Booths and Plazas: W-beam guardrails are often utilized in toll booth areas and plazas to guide traffic and provide a physical barrier between vehicles and toll collection booths. They help maintain traffic flow and ensure the safety of toll booth personnel and motorists.

- Parking Lots and Industrial Areas: W-beam guardrails are also used in parking lots, industrial areas, and other locations where vehicle traffic needs to be separated from pedestrians or protected structures. They create a clear boundary and prevent unauthorized access to restricted areas.

- Bridge and Overpass Protection: Guardrails produced by the W-beam guardrail roll forming machine are employed to protect bridges, overpasses, and other elevated structures. They act as a safety barrier, preventing vehicles from colliding with the edges or falling off the structure in the event of an accident.

- Median Barriers: In the case of divided highways, W-beam guardrails can be installed as median barriers to separate opposing traffic and reduce the risk of crossover accidents.

top 5 electron beam welding machine manufacturers

- Sussman Machinery(Wuxi)Co., Ltd. is specialized in manufacturing shape steel cold roll forming machines about 20 years, exporting slitting line and whole group international trade business.We export to more than 100 countries, and our customers are around the world, especially Australia, South America, Europe, India, Middle East, Northern Europe and North Africa. Furthermore, we wish to build the best machine for customers, our core values are “Quality, Efficiency, Credibility & Integrity”, which can firmly and solidly support us to go far.

- Sciaky Inc. (USA): Sciaky is a leading manufacturer of advanced electron beam welding systems and provides solutions for a wide range of industries including aerospace, defense, automotive, and more. They offer both standard and customized electron beam welding machines with high precision and reliability.

- PVA TePla AG (Germany): PVA TePla specializes in the development and production of electron beam welding systems for various applications. Their machines are known for their advanced technology, precision welding capabilities, and high-quality results. They serve industries such as automotive, aerospace, medical, and energy.

- Carl Zeiss AG (Germany): Carl Zeiss is a renowned manufacturer of optical systems and has a division that produces electron beam welding machines. They offer high-performance electron beam welding systems with advanced features, including process monitoring and control, to ensure accurate and efficient welding processes.

- Electron Beam Engineering (USA): Electron Beam Engineering is a leading manufacturer and service provider of electron beam welding machines. They offer a range of electron beam welding systems, including custom-designed solutions, and provide comprehensive support and services to their customers.

Reviews

There are no reviews yet.