Double layer roll forming machine with 2 profiles can produce two different profile drawings, which can save more space and money compared with two different machines, the material thickness range 0.3-0.8mm or 0.12-0.4mm, material PPGI, stainless steel and galvanized steel

You can choose two different profile drawings, such as:

- Roof sheet and corrugated sheet

- Wall sheet and corrugated sheet

- Roof sheet and wall sheet

- Glazed tile and roof sheet

- Glazed tile and corrugated sheet

Double layer roll forming machine with 2 profiles can not work at the same time, one time only produce one layer profile. There is one clutch as one side of the machine, and you just move one handle wheel to make other layer profile, it takes few seconds, and the whole line only need one person to operate, it is very easy.

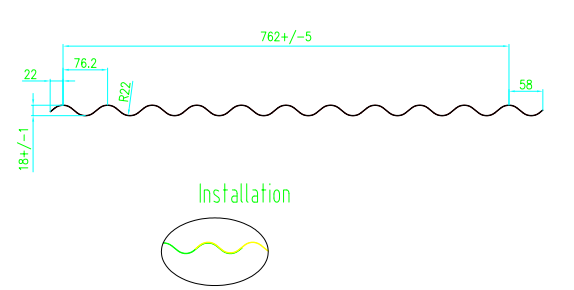

Profile Drawing of double layer roll forming machine with 2 profiles

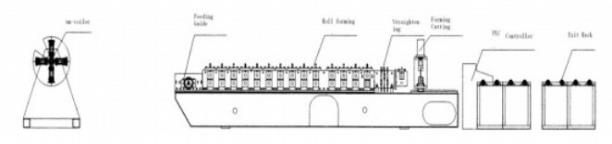

Technological Process of double layer roll forming machine with 2 profiles

Uncoiling——Roll forming—Hydraulic cutting—Products collecting

|

Machine List

|

5 tons manual decoiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| PLC Control box | 1 unit | |

| Hydraulic cutting device | 1 unit | |

| 2m passive table | 2 units | |

| Spare parts | 1 package | |

| Safety cover | 1 set |

Technical Data of double layer roll forming machine with 2 profiles

| Number | Items | Unit\Type | RF-DL |

| 1 | Steel Thickness | mm | 0.11-0.3mm for corrugate,0.3-0.8mm for trapezoidal sheet, Colored Steel / Galvanized Steel Coil |

| 2 | Forming Speed | m/min | 8-15 |

| 3 | Roller stands | stand | Upper layer is about 22 stations Lower layer is about 20 stations |

| 4 | Roller Material | mm | 45# steel, coated with chrome |

| 5 | Shaft material and diameter | mm | Ф75 45# steel, coated with chrome |

| 6 | Main Motor Power | Kw | 7.5 |

| 7 | Hydraulic cutting Power | Kw | 4 |

| 8 | Hydraulic pressure | Mpa | 12 |

| 9 | Power Supply | 380V, 50HZ,3 phase | |

| 10 | Tolerance | mm | -1.5 |

| 11 | Material of cutting | Cr12Mov HRC58-62 | |

| 12 | Control system | PLC with touch screen | |

| 13 | Main machine weight | T | 10T |

| Note:main motor, hydraulic station and control box is under machine frame to save place, touch screen hang over | |||

Details of each composition:

1. Uncoiler: 5 tons manual de–coiler

- Coil inner Diameter: ¢460-520mm

- Max out diameter of the coil: ¢1250mm

- Max Coil Width: 1250mm

2. Hydraulic Cutting

- Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

- Material of blade: CR12Mov with heat treatment

- Length measuring: Automatically

- The cutting thickness:0.5-1.0mm

- Hydraulic Station Power: 4kw

3. 2 meters passive table

It adopts welded steel and supported roller to transmit the products.

Size: 2000*1300*800mm

4. Control Box

(1) Power supplier: 380V, 50 Hz, 3Phase

(2) Length & quantity measurement automatically;

(3) Length & quantity controlled by PLC

(4) Length inaccuracy can be amended easily.

(5) Control panel: Button-type switch and touch screen

(6) Unit of length: millimeter (switched on the control panel)

What is double layer roll forming machine?

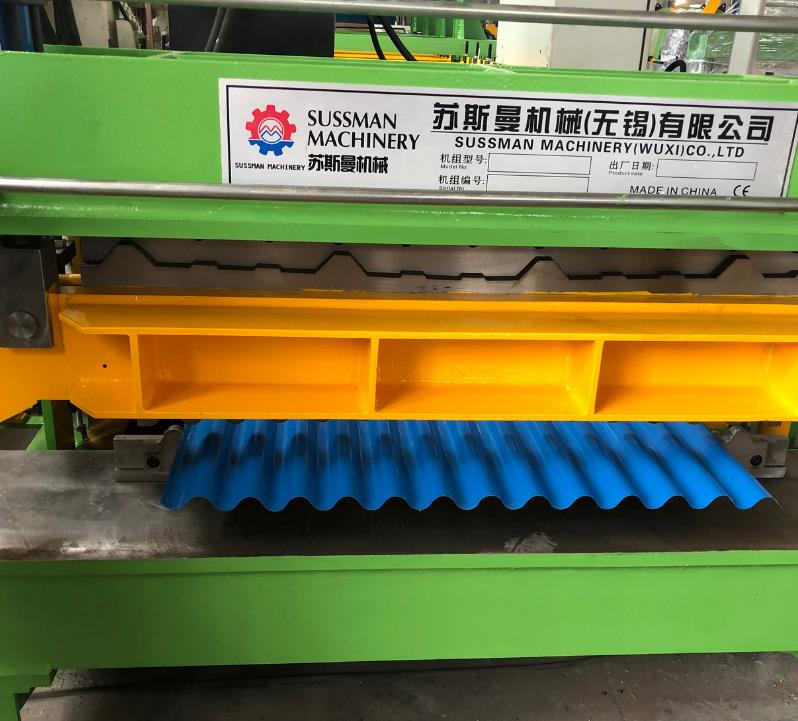

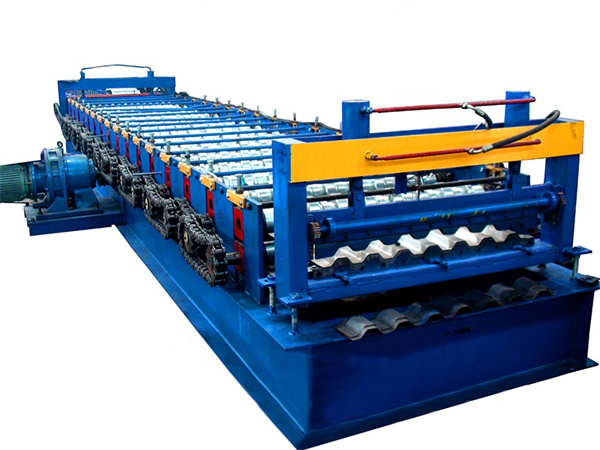

A double layer roll forming machine is a type of machinery used in the manufacturing industry to produce two different types of profiles or layers simultaneously. It is commonly used in the production of metal roofing sheets or wall panels where two layers of different materials or profiles are required.

The machine consists of a series of rollers and tooling sets that shape the metal coil into the desired profiles. Each layer or profile has its own set of rollers and tooling, allowing for the simultaneous formation of two distinct profiles. The machine operates by feeding a continuous metal coil through the rollers, which gradually shape the metal into the desired profiles.

Double layer roll forming machines offer several advantages over single-layer machines. They increase production efficiency by eliminating the need for separate machines or processes to create each profile. They also save space on the factory floor and reduce labor costs. Additionally, these machines provide flexibility in terms of profile designs and materials, allowing manufacturers to produce a wide range of products to meet customer demands.

Overall, double layer roll forming machines are versatile and efficient manufacturing tools used for the simultaneous production of two different profiles or layers, typically employed in the production of metal roofing sheets and wall panels.

What about double layer roll forming machine price?

The price of a double layer roll forming machine can vary depending on several factors, including the machine’s specifications, quality, brand, and the region where it is purchased. Additionally, market fluctuations and other economic factors can also impact the price. As an AI language model, I don’t have access to real-time pricing information. Therefore, it is best to consult with manufacturers, suppliers, or industry professionals to get the most accurate and up-to-date information on pricing.

When considering the price of a double layer roll forming machine, it’s essential to consider not only the upfront cost but also the long-term value it provides. Factors such as the machine’s durability, reliability, ease of use, maintenance requirements, and customer support should be taken into account. Investing in a high-quality machine from a reputable manufacturer can often result in better performance, longevity, and overall cost-effectiveness in the long run.

Working principle of double layer cold roll forming machine?

The working principle of a double layer cold roll forming machine involves a series of steps that transform a continuous metal coil into two different profiles or layers simultaneously. Here is a general overview of the working principle:

- Coil Loading: The process begins by loading the metal coil onto a decoiler, which holds and feeds the coil into the roll forming machine. The coil is typically made of steel or another metal.

- Material Straightening: The coil passes through a straightening unit that removes any coil curvature or distortions, ensuring a smooth and even feed into the forming section.

- Profile Design and Tooling Setup: The machine is equipped with two sets of rollers and tooling for each layer or profile. The profile designs and tooling are determined based on the desired dimensions and specifications of the final products.

- Forming Process: The metal coil enters the forming section, where a series of rollers gradually shape the coil into the desired profiles. The rollers apply bending and shaping forces to the metal, progressively forming it into the specified shape and size. The upper and lower sets of rollers correspond to the two layers or profiles being produced simultaneously.

- Cutting and Shearing: Once the desired lengths of the profiles are achieved, the machine incorporates cutting mechanisms to cut the profiles into individual pieces. This may involve flying cutoff techniques or stationary shearing methods, depending on the specific machine design.

- Stacking and Collection: The cut profiles are typically stacked and collected on an output conveyor or stacking system for further processing or packaging.

Throughout the process, the machine operator monitors and adjusts various parameters, such as roller positions, speeds, and tensions, to ensure precise forming and cutting. The double layer cold roll forming machine operates at ambient temperature, without the need for additional heat or thermal treatments.

It’s important to note that specific machine configurations and variations may exist depending on the manufacturer and the intended application of the double layer cold roll forming machine.

Reviews

There are no reviews yet.