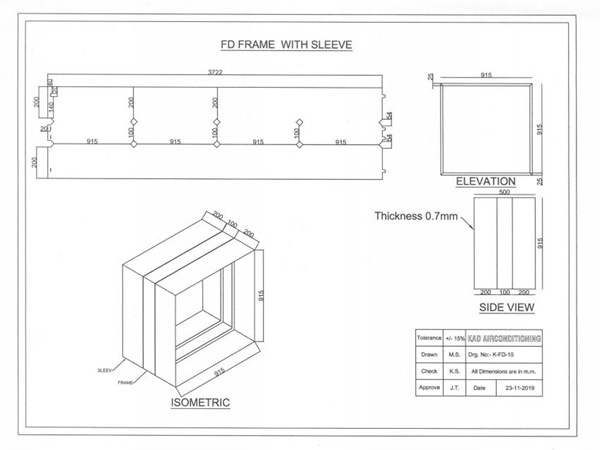

Parameter

| Description | |

| Items | Specifications |

| Material Thickness |

1.5 mm galvanized coils

|

| Un Coiler | 3 tons manual |

| Rolling Speed | About 10m/min |

| Roller Stations |

About 12 stations

|

| Roller Material |

Gcr15 coated with chrome

|

| Maim Motor Power | 7.5kw |

| Motor cutting Power | 5.5kw |

| Material Of Cutting |

CR12mov with quench treatment

|

| Hardness | HRC58-62 |

| Control System |

PLC (Panasonic) as list in the note

|

| Weight | About 8 tons |

| Way Of Drive | 1.2 inch chain |

Technological process:

Uncoiling——Servofeeding——hydraulicPunching—Rollforming—Cutting ——Products collecting

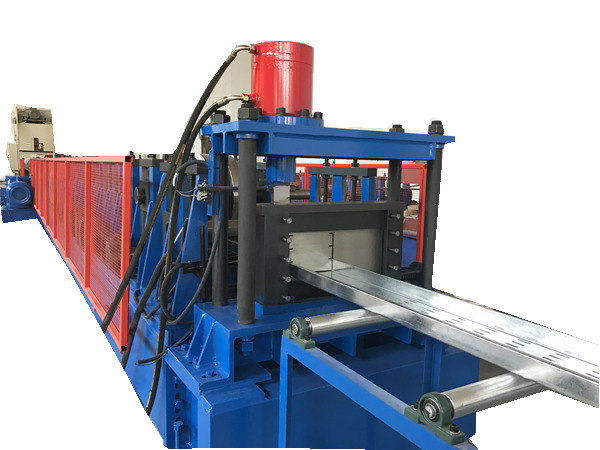

The external of Fire Damper Roll Forming Machine

| Items |

Specifications

|

|

|

Material of coil

|

Material Thickness |

1.0-1.5 mm galvanized coils

|

| Un Coiler | 3 tons hydraulic | |

| Servo feeding | Motor | Delta 1.8kw |

| Punching device | Punching |

4 sets of punching die

|

|

Forming system

|

Forming Speed |

About 2-3pieces/min

|

| Roller Stations | About 16 stations | |

| Roller Material |

Gcr15 coated with chrome

|

|

| Maim Motor Power | 7.5kw | |

| Motor cutting Power | 5.5kw | |

|

Cutting

system |

Material Of Cutting |

CR12mov with quench treatment

|

| Hardness | HRC58-62 | |

| Tolerance | ±1.5mm | |

| Cutting blades | 1 set | |

|

Electrical control system

|

Electric Source |

380V, 50HZ,3 phase

Also, can satisfy Customer’s requirey |

| Control System |

PLC Delta as list in the note

|

|

| Weight | About 8 tons | |

| Way Of Drive | 1.2 inch chain | |

| Machine size | mm |

10000mm*700mm*1000mm

|

Details of each composition

1. De-coiler: 3 ton hydraulic de-coiler

2. Hydraulic punching with servo feeder

3. Hydraulic cutting device

- Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

- Material of blade: CR12 with heat treatment

- Length measuring: Automatically

- Tolerance of length: + 1.5mm

4. Control Box

- Power supplier: 380 V, 50 Hz, 3Phase (adjusted with the requestment)

- Length & quantity measurement automatically;

- Length & quantity controlled by PLC, Delta

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- Unit of length: millimeter (switched on the control panel)

Reviews

There are no reviews yet.