A cable tray system, is “a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways.” Cable trays are used to hold up and distribute cables. Cable tray roll forming machine is special designed for its production.

Cable tray roll forming machine for Steel ladder type consists of decoiler (uncoiler), leveling machine (flattener), servo feeding device, punching system, front cutting device, guiding device, roll former, rear straightening device and run-out table. With full and special experience, we can customize cable tray roll forming machines or cable tray roll forming production lines according to customers’ profile drawings and specifications.

Features

- High Quality

- Reliable and durable

- Reasonable Price

- Good after-Sales Service

- 1-Year Warranty

Specification

| Suitable Material |

0.8-2.0mm, width as the design

|

| Decoiler |

3T/5T/8T decoiler

|

| Forming Station |

20 stations up to the profile

|

| Forming Speed | Max 20 m/min |

| Panel Run Out | Run Out Table |

| Total Power |

About 50 KW up to final design

|

| Total Installation Size |

45 X 5 m up to final design

|

Application

A cable tray system, is a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways.” Cable tray roll forming machine for Steel ladder type are used to hold up and distribute cables. Cable tray roll forming machine is special designed for its production.

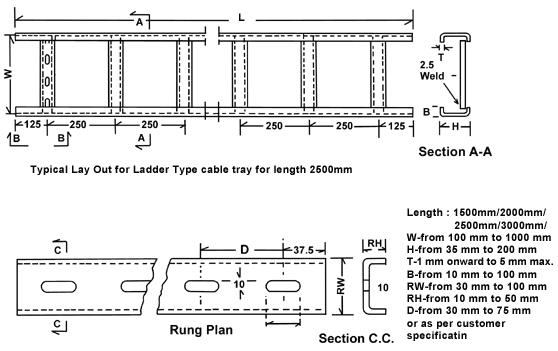

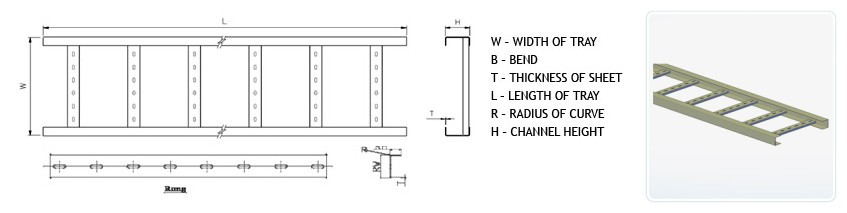

Profile drawings for options

Briefly introduce cable tray roll forming machine

A cable tray roll forming machine is a specialized industrial equipment used for the manufacturing of cable trays. Cable trays are structural components used to support and organize electrical cables and wires in buildings, data centers, industrial facilities, and other infrastructure projects. The roll forming machine is designed to produce cable trays with precise dimensions and consistent quality.

The cable tray roll forming machine operates by feeding a metal coil strip, typically made of steel or aluminum, into a series of rollers. These rollers gradually bend and shape the metal strip into the desired profile of the cable tray. The machine may include various stations for performing additional operations such as punching holes, cutting to length, and forming connection joints.

advantages of china cable tray roll forming machine

- Flexibility: The machine can produce a wide range of cable tray profiles, including ladder-type, perforated, solid-bottom, and wire mesh designs. It can also accommodate various sizes and thicknesses of the metal strip, allowing for customization to meet specific project requirements.

- High Efficiency: The roll forming process enables continuous production, resulting in high production rates. The machine can produce cable trays in a fast and efficient manner, optimizing manufacturing productivity.

- Precision and Consistency: The roll forming machine ensures accurate shaping and consistent dimensions of the cable trays. This precision is crucial for the proper fit and installation of the cable trays, ensuring the safe and efficient routing of electrical cables.

- Automation and Integration: Cable tray roll forming machines are often equipped with advanced automation features, such as computerized control systems and touchscreen interfaces. This allows for easy operation, quick setup, and seamless integration with other downstream processes in the production line.

- Cost-effectiveness: By eliminating the need for manual fabrication and minimizing material waste, the cable tray roll forming machine offers cost savings in terms of labor, time, and material utilization. It enables efficient and economical production of cable trays.

top 5 cable tray roll forming machine factory in China

- Sussman Machinery(Wuxi)Co., Ltd. export to more than 100 countries, and our customers are around the world, especially Australia, South America, Europe, India, Middle East, Northern Europe and North Africa. Furthermore, we wish to build the best machine for customers, our core values are “Quality, Efficiency, Credibility & Integrity”, which can firmly and solidly support us to go far.

- Hangzhou Roll Forming Technology Co., Ltd. Hangzhou Roll Forming Technology is a reputable manufacturer specializing in roll forming machines, including cable tray roll forming machines. They offer a wide range of models with advanced features and customization options.

- Botou Huayang Trading Co., Ltd. Botou Huayang Trading is a prominent manufacturer and exporter of roll forming machines, including cable tray roll forming machines. They have extensive experience in producing high-quality machines and have a strong presence in the global market.

- Jiangsu Huazhong RollForming Machine Co., Ltd. Jiangsu Huazhong RollForming Machine is a leading manufacturer of roll forming machines, catering to various industries, including cable tray production. They are known for their advanced technology, precision engineering, and reliable machines.

- Shanghai MTC Industrial Co., Ltd. Shanghai MTC Industrial is a well-known manufacturer and supplier of roll forming machines, including cable tray roll forming machines. They offer a wide range of models, providing flexibility and customization options to meet customer requirements.

Reviews

There are no reviews yet.