Description

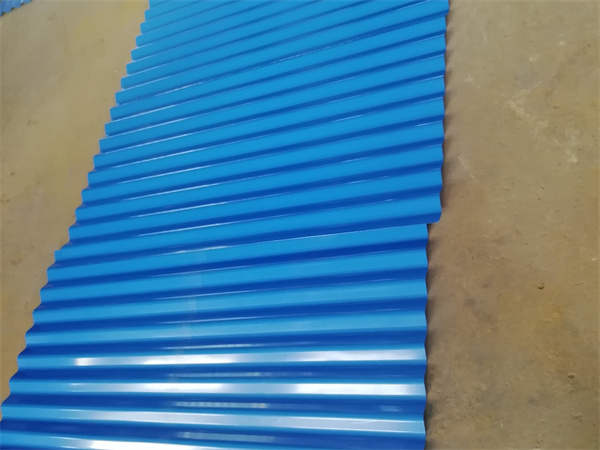

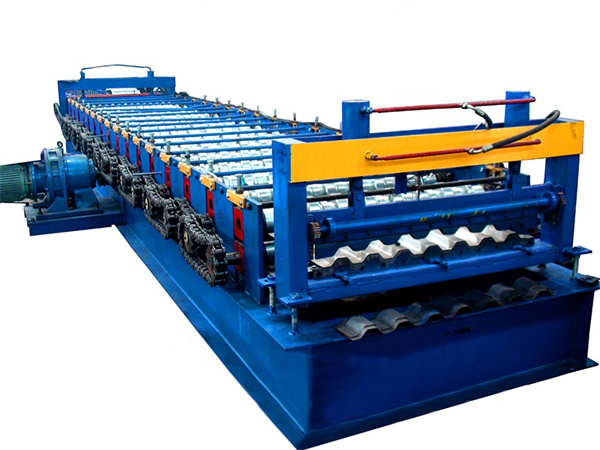

High speed PPGI corrugated sheet roll forming machine can produce material thickness range 0.3-0.8mm or 0.12-0.4mm, material PPGI, galvalume steel and galvanized steel, also we can customized the High speed PPGI corrugated sheet roll forming machine according to your drawing, for the machine speed, we can do normal speed 8-12m/min, drives by chain; also we can do high speed 30-40m/min, it drives by gearbox, its products are widely used in roof and wall system in workshop construction and housing construction.

Technical process

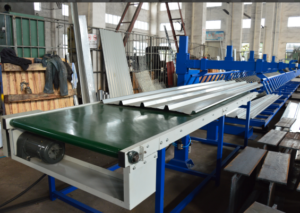

Decoiler→ feeding with guide→roll forming→servo following cutting→conveyor belt→Stackers

Technical parameter

1.Rolling Speed: about 30-40m/min

2.Materials to be processed: Galvanized steel, Aluzinc, PPGI from 0.2 mm to 0.6 mm

3.Maximum length of the sheet to be unloaded: 6 m

4.Control System: PLC with touch screen

5.Roller Stations: about 22 stations

6.Roller Material : 45# forge steel, coated with chrome

7.Shaft Material and DIA: ¢76mm,material is 45# forge steel, Chrome with quenching

8.Motor Power: 22kw main motor

9.Hydraulic power:7.5kw

10.Power supplier:380V, 50HZ,3 phase

11.Way Of Drive: Gearbox drive

12.The size of the forming machine: About 11,500*1700*1200mm

13.Machine weight: about 15 tons

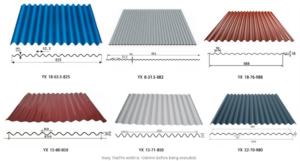

Profile Drawing

Machine List

| Machine list | 10 tons de-coiler with arm device | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| Servo following cutting | 1 set | |

| Control box | 1 unit | |

| Hydraulic station | 1 unit | |

| 3 meters conveyor belt | 1 set | |

| 6m auto stacker | 1 set | |

| Safety cover | 1 set | |

| Spare parts | 1 package |

Technical Data

-

10 tons hydraulic de-coiler with coil car

Coil inner Diameter: ¢460-520mm

Max out diameter of the coil: ¢1250mm

Max Coil Width: 1250mm

-

Servo following Cutting device

(1) Cutting motion: Servo following cutting

(2) Material of blade: CR12mov with heat treatment

(3) Length & quantity measurement automatically;

(4) The cutting thickness: 0.2- 0.6mm

(5) Hydraulic Station Power: .5 KW

-

Control Box

(1) Power supplier: 380V, 50 Hz, 3Phase (adjusted with the requestment)

(2) length & quantity measurement automatically;

(3) length & quantity controlled by PLC

(4) Length inaccuracy can be amended easily.

(5) Control panel: Button-type switch and touch screen

(6) Unit of length: millimeter (switched on the control panel)

-

3 meters conveyor belt

-

6 meters auto stacker

What is sheet metal roll forming machines?

Sheet metal roll forming machines are industrial machines used for shaping and forming continuous lengths of sheet metal into desired profiles. They are commonly used in manufacturing processes for various industries such as construction, automotive, aerospace, and appliances.

The roll forming process involves feeding a strip of sheet metal through a series of rollers, gradually bending and shaping it into a specific profile. The machine consists of a set of adjustable rollers, each designed to perform a specific bending or shaping operation. These rollers are positioned in a sequence, and as the metal strip passes through them, it undergoes continuous shaping until it reaches the desired profile.

Sheet metal roll forming machines can produce a wide range of profiles, including C-channels, Z-sections, U-channels, hat sections, and many others. The machines can be customized with different tooling and roller configurations to accommodate specific profile requirements.

Roll forming offers several advantages over other metal forming processes. It allows for high production rates, consistent quality, and precise control over the final shape and dimensions of the profile. Additionally, roll forming machines can handle a variety of metals, including steel, aluminum, and stainless steel.

application of corrugated sheet roll forming machine

- Roofing and Cladding: Corrugated metal sheets are widely used for roofing and cladding purposes in residential, commercial, and industrial buildings. The sheets provide durability, weather resistance, and excellent drainage capabilities, making them ideal for protecting structures from the elements.

- Construction and Infrastructure: Corrugated metal sheets are used in construction projects for applications such as wall panels, partition walls, ceiling systems, and flooring. They offer structural strength, fire resistance, and can be used as load-bearing elements in some cases.

- Agricultural Structures: Corrugated sheets are commonly employed in agricultural buildings such as barns, sheds, and storage facilities. They provide a cost-effective solution for protecting livestock, crops, and equipment from harsh weather conditions.

- Transportation and Automotive: Corrugated sheets are utilized in the manufacturing of transportation vehicles, including trailers, truck bodies, and shipping containers. The sheets offer lightweight construction, high strength, and resistance to impact and vibrations.

- Industrial Applications: Corrugated sheets find application in industrial settings for purposes such as wall cladding, acoustic panels, machine enclosures, and ductwork. Their versatility, ease of installation, and durability make them suitable for various industrial environments.

- Decorative and Architectural Elements: Corrugated metal sheets are also used in architectural projects for decorative purposes, facades, interior design, and artistic installations. The unique pattern and texture of the corrugations can add visual interest and a contemporary look to buildings.

How much does corrugated roof sheet roll forming machine?

The cost of a corrugated roof sheet roll forming machine can vary depending on several factors, including the machine’s specifications, quality, features, and the manufacturer or supplier. The price can also be influenced by factors such as the complexity of the profile, the material used, and any additional customization options.

Generally, corrugated roof sheet roll forming machines can range in price from a few thousand dollars to tens or even hundreds of thousands of dollars. Entry-level or smaller machines with basic features and lower production capacities tend to be more affordable, while larger, high-capacity machines with advanced features and customization options will typically have a higher price tag.

It is important to consider not only the initial cost of the machine but also its long-term value, reliability, and support provided by the manufacturer. It is advisable to research and compare different suppliers, request quotes, and consider factors such as warranty, after-sales service, and customer reviews before making a purchasing decision.

It’s worth noting that the above information is a general estimate, and specific prices can vary significantly depending on the factors mentioned above. To get an accurate and up-to-date price for a corrugated roof sheet roll forming machine, it is recommended to contact manufacturers, suppliers, or industry experts who specialize in roll forming equipment.

Reviews

There are no reviews yet.