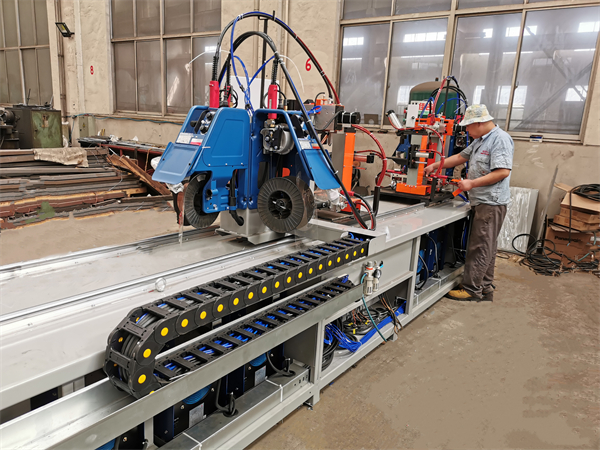

Joint Rack steel beam roll forming machine Machine parts list

| S.N | Equipment name | Quantity |

| 1 | 3T hydraulic de-coiler with coil car | 1 set |

| 2 | Main roll forming machine | 1 set |

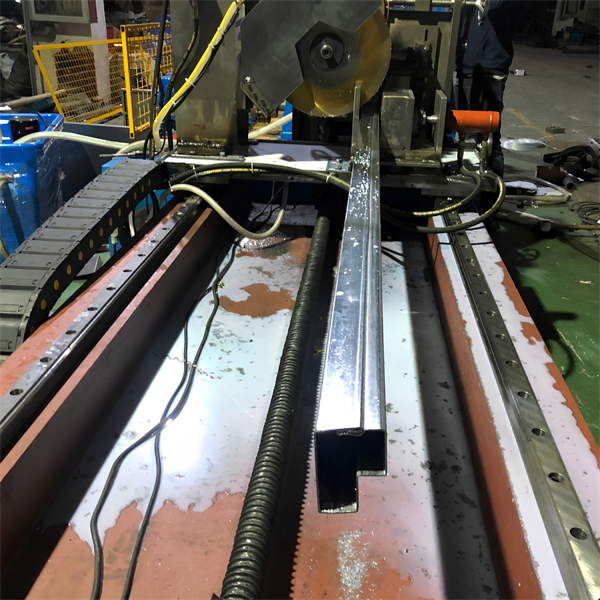

| 3 | Fly saw cutting | 1 set |

| 4 | Control system ( including control box) | 1 set |

| 5 | 6 meters out table | 1 unit |

| 6 | Spare parts | 1 package |

| 7 | Cooling system | 1 set |

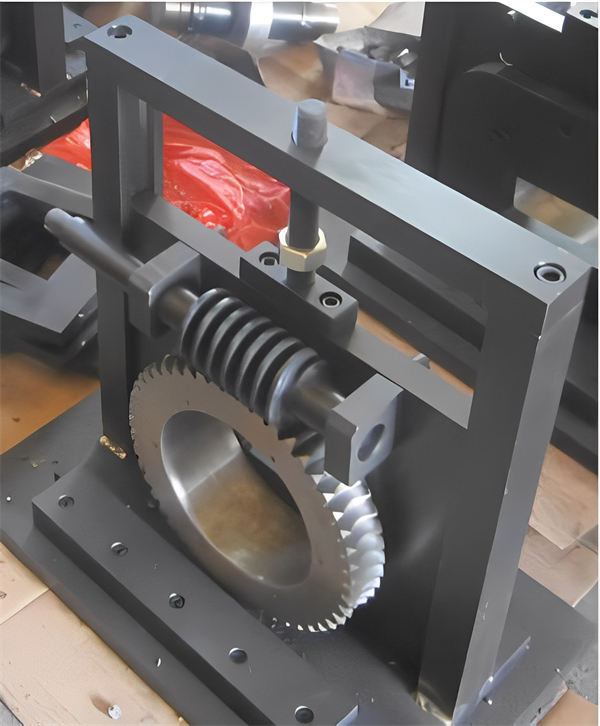

| 8 | Gear box driven | 1 set |

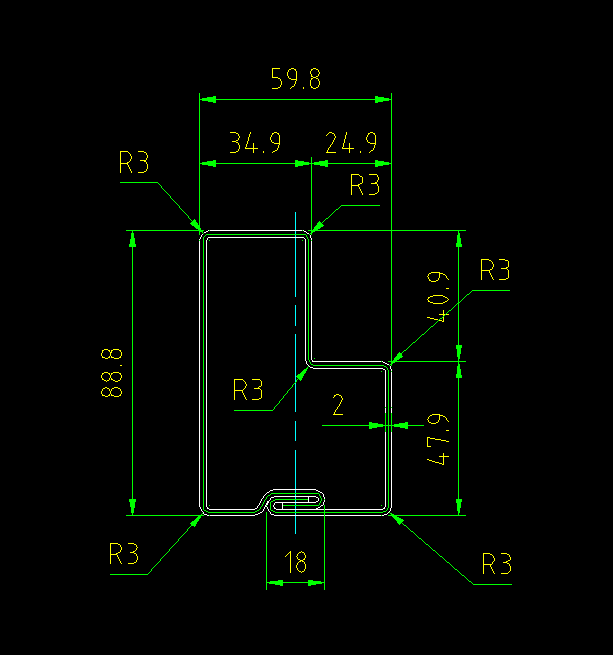

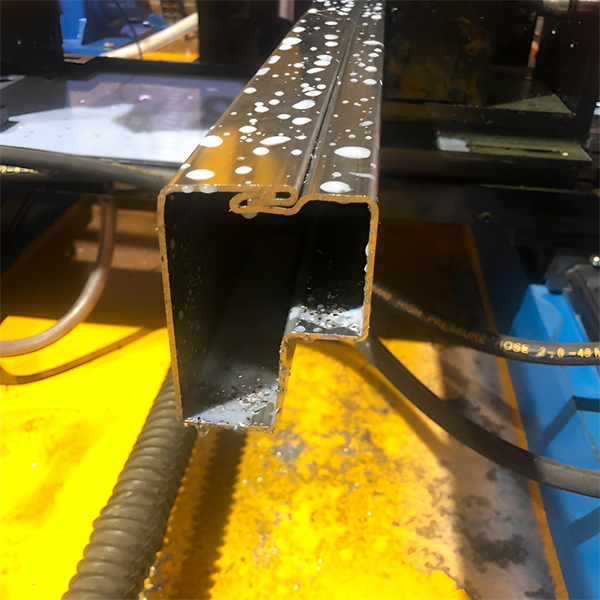

Profile drawings

Machine Layout

Technique data

1. 3 ton hydraulic De-coiler& coil car

- Diameter: 460-520mm expansion.

- Expansion: hydraulic

- Capacity: 3000kg per mandrel

- Max Coil Width: 500mm

- Drag tension brake with variable brake tension adjustment valve

2. Leveling device

- 7 rolls leveling, 3 rolls up and 4 rolls down, roller leveler rolls are smaller, get flatting better

- Diameter is Ø70mm, chrome and HRC60 heat treatment to secure the smooth surface

3. Main Roll forming machine technique data

- Suitable Plate Material: thickness 1.2-2mm, Galvanize steel or black steel

- Working Line Speed: 0-10meters / min

- Forming machine:about 26 stations

- Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

- Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermalrefining

- Driven system: gear box driven

- Main Power with reducer: 15KWWH Chinese Famous

- Cutting: Hydraulic CuttingCr12mov

- Material of Cutting Knife: Cr12Mov, Quench HRC58-62

- 10. The whole machine is controlled by industry computer-PLC.

- PLC–Panasonic, Japan English and Chinese Language

- Touch Screen–Delta

- Encoder–Omron, Japan

- Electric parts–Schneider

4. Main roll forming machine share list

- De-coilerwith coil car

- main frame of the machine

- Main Motor

- PLC Control box

- fly saw cutting

- Out tables

- Cooling system

What is box beam roll forming machine?

A box beam roll forming machine is a type of industrial machinery used in the manufacturing process of box beams. Box beams are structural components that are commonly used in various industries, such as construction, transportation, and storage systems.

The roll forming machine is designed to shape and form continuous metal strips or coils into box beam profiles. It consists of a series of rollers that gradually bend the metal strip into the desired shape. The rollers are strategically positioned along the machine, and each roller performs a specific bending or forming operation on the metal.

The box beam roll forming machine typically includes multiple sets of rollers, with each set responsible for shaping a specific part of the box beam. The machine may have additional accessories and components to cut the formed beams to the desired lengths or add specific features, such as holes or slots, to the beams.

The roll forming process is highly efficient and allows for the continuous production of box beams with consistent dimensions and quality. It is a cost-effective method for mass production, as it eliminates the need for individual piece fabrication.

Box beams manufactured using roll forming machines are known for their strength, durability, and versatility. They are widely used in applications such as building frames, conveyor systems, racking systems, and support structures.

It’s worth noting that specific designs and capabilities of box beam roll forming machines can vary depending on the manufacturer and the intended application.

application of pallet rack roll forming machine

- Warehousing and Storage Systems: Pallet rack roll forming machines are used to manufacture the main components of pallet racking systems, including upright frames and horizontal beams. These components are essential for creating efficient storage systems that maximize vertical space and allow for easy access to goods.

- Logistics and Distribution Centers: Pallet racks are commonly used in logistics and distribution centers to store and organize products for efficient inventory management and order fulfillment. Roll-formed pallet racks enable the safe and organized storage of goods, facilitating easy loading and unloading using forklifts or other material handling equipment.

- Retail and E-commerce Facilities: Retailers and e-commerce companies rely on pallet racks to store and display products in their warehouses and fulfillment centers. The roll forming machines are used to manufacture racks that can accommodate a wide range of products, from large and bulky items to smaller boxes and cartons.

- Manufacturing and Industrial Facilities: Pallet racks are utilized in manufacturing and industrial environments to store raw materials, work-in-progress (WIP), and finished goods. The roll-formed racks provide sturdy support for heavy loads, making them suitable for storing industrial components, machinery parts, and other materials.

- Automotive Industry: Pallet racks find extensive use in the automotive industry for storing components, tires, and other automotive parts. The roll forming machines produce racks with specific dimensions and load-bearing capacities to meet the unique requirements of the automotive sector.

- Cold Storage and Food Industry: Pallet racks designed for cold storage and food industry applications are manufactured using specialized roll forming machines. These racks are designed to withstand low temperatures and are suitable for storing perishable goods, frozen products, or food and beverage inventory.

Which fields are the main applications of rack shelf roll forming machine?

- Warehousing and Logistics: Rack shelves are widely used in warehouses and distribution centers for efficient storage and organization of goods. Rack shelf roll forming machines are used to produce sturdy and customized shelving units that can withstand heavy loads and facilitate easy access to stored items.

- Retail and Display: Rack shelves are commonly used in retail stores and supermarkets to showcase and organize products for sale. Roll forming machines are employed to manufacture various types of display racks, such as gondola shelves, pegboard shelves, and slatwall shelves, which are designed to enhance product visibility and maximize retail space utilization.

- Industrial Storage: Many industries require specialized storage systems to store heavy equipment, tools, and supplies. Rack shelf roll forming machines are utilized to produce heavy-duty industrial shelving units, such as pallet racks, cantilever racks, and boltless racks, which are designed to handle substantial loads and provide efficient storage solutions for factories, workshops, and warehouses.

- Automotive Industry: In the automotive sector, rack shelves are used for storing components, spare parts, and tools. Roll forming machines can manufacture specific shelving designs tailored to the automotive industry’s requirements, ensuring optimal organization and accessibility of items in repair shops, garages, and automotive manufacturing facilities.

- E-commerce and Fulfillment Centers: With the rapid growth of e-commerce, efficient storage and order fulfillment systems are crucial. Rack shelf roll forming machines play a vital role in producing shelving units for e-commerce warehouses and fulfillment centers, enabling efficient inventory management, order picking, and packing processes.

- Document and Archive Storage: Rack shelves are utilized in offices, libraries, and archival facilities for storing documents, files, and records. Roll forming machines can produce specialized shelving systems, such as archive shelving, file racks, and document storage solutions, ensuring proper organization, easy retrieval, and protection of important paperwork.

Reviews

There are no reviews yet.