For Roll forming machine company for Fence guide Rail system, we need three machines, which is fencing sheet machine, fencing post machine, fence rail machine, the material thickness is 0.4-0.7mm, material will be galvanized steel or color steel, automatic cut any length you want, fencing is very popular in Australia, New Zealand.

The Roll forming machine company for Fence guide Rail is a complete production line for the manufacture of metal fencing profiles with notched edge or slotted holes for supporting on a metal fencing system.

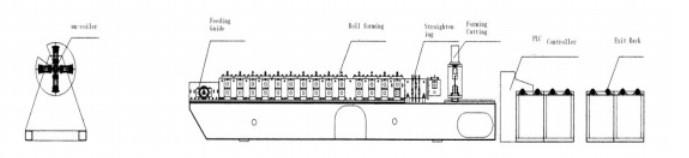

The Roll forming machine company for Fence guide Rail consists of decoiler, hydraulic punching device, roll forming system, and cut to length by hydraulic cutting, receiving table, etc.

The Roll forming machine company for Fence guide Rail can be installed on top of limestone walls with panels stepped, post and rail fencing is a traditional and cost-effective form of fencing. Its simple design makes it the ideal choice for a DIY project, especially on sloping sites and uneven ground, and it is widely used for house garden, school, factory, etc.

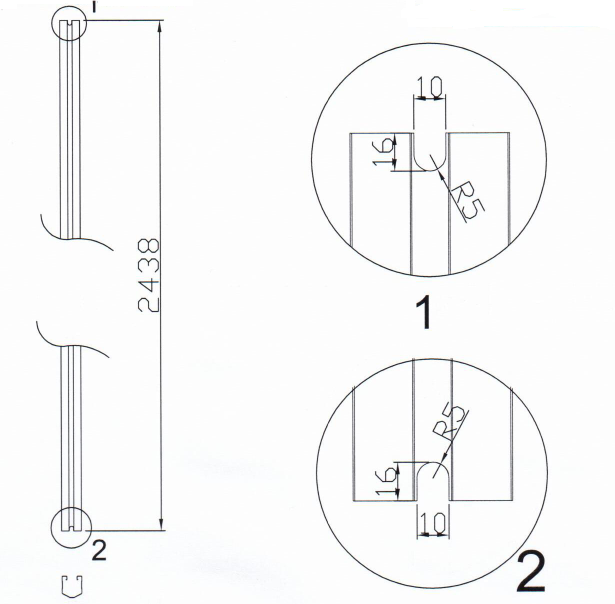

Profile of the product

(Basis on customer’s requirement to design)

Technological process

Uncoiling—feeding with guide—Hydraulic punching—Roll forming——Cutting—Products collecting

|

Machine list

|

3 ton manual de-coiler | 1 set |

| Feeding with guide | 1 set | |

| Hydraulic punching | 1 set | |

| Main roll forming machine | 1 set | |

| Hydraulic cutting device | 1 set | |

| PLC Control box | 1 set | |

| Hydraulic station | 1 set | |

| 4m out table | 1 set | |

| Safety cover | 1 set |

The external of machine

| Items |

Specifications

|

|

| Material of coil | Material Thickness |

0.5-0.7mm galvanized, G235-350Mpa

|

| Un Coiler | 3 tons manual | |

| Forming system | Rolling Speed |

About 10-20 m/min

|

| Roller Stations |

About 19 stations

|

|

| Roller Material |

45# Steel with quenching 60mm shaft

|

|

| Maim Motor Power | 7.5 kw | |

| Hydraulic cutting Power | 3 kw | |

| Cutting system | Material Of Cutting |

CR12 with quench treatment

|

| Hardness | HRC58-62 | |

| Tolerance | ±1.5mm | |

| Electrical control system | Electric Source |

380V, 50HZ,3 phase

Also can satisfy Customer’s require |

| Control System |

PLC with touch screen

|

|

| Weight | About 3.5 tons | |

| Way Of Drive |

1 inch single chain

|

|

| Size of machine |

Length 9500mm* Width 800mm* Height 1500mm

|

Details of each composition

1.Decoiler

- 3 tons passive decoiler

- Diameter: 460-520mm expansion.

- Expansion:manaul

- Capacity: 3000kg per mandrel

2. Hydraulic punching

3. Hydraulic Cutting

- Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

- Material of blade: CR12mov with heat treatment

- Length measuring: Automatically

- Tolerance of length: + 1.5mm

- In order to get the perfect profiles, we recommend the post hydraulic cutting by changing the cutting moulds. It is easy to operate.

4. Out Table

- Length : 4 meters

- Quantity: 1 units

5. Control Box

- Power supplier: 380V, 50 Hz, 3Phase (adjusted with the requirement)

- Length & quantity measurement automatically;

- Length & quantity controlled by PLC,

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- The language in the touch screen: English and Chinese

- Unit of length: millimeter (switched on the control panel)

what is guide rail roll forming machine?

A guide rail roll forming machine is a specialized piece of equipment used in the manufacturing industry to produce guide rails or guardrails. Guide rails are commonly used in various applications, including highways, railways, warehouses, and industrial facilities, to provide safety and guidance for vehicles, equipment, or pedestrians.

The roll forming process involves feeding a continuous strip of metal into the machine, which then passes through a series of rolls or rollers. These rolls gradually shape the metal strip into the desired profile of the guide rail. The rolls are specifically designed to form the metal strip into the required shape, typically featuring grooves, flanges, or other features.

The guide rail roll forming machine can handle different types of metals, such as steel, aluminum, or stainless steel, depending on the application and requirements. It often incorporates various components, including decoilers, leveling units, punching units, and cutting systems, to perform specific operations during the roll forming process.

By using a guide rail roll forming machine, manufacturers can efficiently produce guide rails in large quantities with consistent quality and precise dimensions. The machine’s automation and precision enable high-speed production while minimizing material waste.

applicaiton of fence roll forming machine

A fence roll forming machine is a specialized piece of equipment used in the manufacturing industry to produce fences of various types. It is designed to efficiently and accurately form continuous metal strips into the desired profiles and shapes needed for different fence designs. Here are some applications of a fence roll forming machine:

- Residential Fencing: Fence roll forming machines are commonly used to manufacture fences for residential properties. These fences can be made of materials such as steel, aluminum, or PVC, and come in different styles, including picket fences, privacy fences, and ornamental fences.

- Agricultural Fencing: The machine is utilized in producing fences for agricultural purposes, such as livestock enclosures, farm boundaries, and animal control. These fences are typically designed to be sturdy and durable, ensuring the safety and security of animals and crops.

- Industrial Fencing: Fence roll forming machines are used to manufacture fences for industrial applications, including perimeter security for factories, warehouses, and industrial facilities. These fences often incorporate additional security features like barbed wire, razor wire, or anti-climbing structures.

- Highway and Road Fencing: Fences are essential for highway and road infrastructure to provide safety, control access, and separate different areas. Fence roll forming machines are employed to produce highway and road barriers, guardrails, and sound barriers.

- Sports and Recreation Fencing: The machine is used to manufacture fences for sports fields, parks, playgrounds, and recreational areas. These fences ensure the safety of participants and define the boundaries of the playing area.

- Temporary Fencing: Fence roll forming machines are also used to produce temporary fencing solutions for construction sites, events, or crowd control purposes. These fences are designed to be easily installed, removed, and transported.

The flexibility and versatility of fence roll forming machines make them suitable for various applications in the fencing industry. They enable efficient production, consistent quality, and customization options for different fence designs, sizes, and materials.

Reviews

There are no reviews yet.