For Roll forming machine China for Automatically PPGI Fence Panel system, we need three machines, which is fencing sheet machine, fencing post machine, fence rail machine, the material thickness is 0.4-0.7mm, material will be galvanized steel or color steel, automatic cut any length you want, fencing is very popular in Australia, New Zealand.

The Roll forming machine China for Automatically PPGI Fence Panel consists of decoiler, roll forming system, and cut to length by hydraulic cutting, receiving table, etc.

Roll forming machine China for Automatically PPGI Fence Panel can be installed on top of limestone walls with panels stepped, post and rail fencing is a traditional and cost-effective form of fencing. Its simple design makes it the ideal choice for a DIY project, especially on sloping sites and uneven ground, and it is widely used for house garden, school, factory, etc.

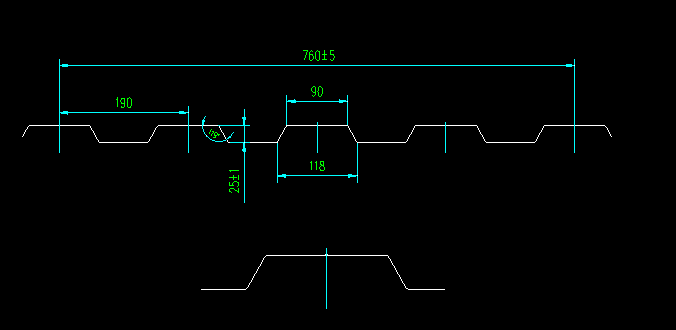

Profile of the product

(Basis on customer’s requirement to design)

Technological process

Uncoiling—Feeding with guide——Roll forming—Cutting—Products collecting

|

Machine list

|

5 tons passive de-coiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| PLC Control box | 1 unit | |

| Hydraulic cutting device | 1 unit | |

| Out tables | 2 units | |

| Safety cover | 1 set |

Technical Data

1. Un-coiler

- 5 tons passive decoiler

- Coil inner Diameter: ¢450-550mm

- Max out diameter of the coil:¢1500mm

- Max Coil Width: 1250mm

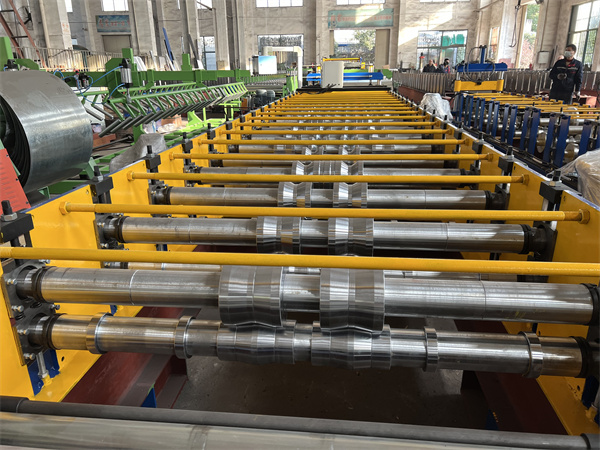

2. Roll forming machine

- Rolling Speed: About 8-12m/min

- Steel sheet Thickness: 45 mm to 0.7mm PPGI,Galvanized Steel

- Roller Stations:about 18 stations

- Roller Material : 45# forge steel, coated with chrome

- Shaft Material and DIA: ¢76mm,material is 45# forge steel, Chrome with quenching

- MainMotor Power:5kw

- Hydraulic Pressure:12Mpa

- Power supplier: 380V, 50HZ,3 phase or customized as customer’s requirement

- Way Of Drive:bychain

- Color Of The Machine:blue or customized

- The size of the forming machine:About 8500*1500*1500mm

- Machine weight: about 8 tons

- Control system: PLC control panel with touching screen

3. Hydraulic Cutting

- Cutting motion: The main machine stops and then cut automatically. After cutting, the main machine re-starts automatically.

- Material of blade: CR12Mov with heat treatment

- Length measuring: Automatically

- The cutting thickness: 0.3- 0.8mm

- Hydraulic Station Power: 4 KW

4. Out table

- It adopts welded steel and supported roller to transmit the products.

- Size:4000*1350*1200mm

5. Control Box

- Power supplier: 380V, 50 Hz, 3Phase (adjusted with the requirement)

- Length & quantity measurement automatically;

- Length & quantity controlled by PLC,

- Length inaccuracy can be amended easily.

- Control panel: Button-type switch and touch screen

- The language in the touch screen: English and Chinese

- Unit of length: millimeter (switched on the control panel)

what is metal roof panel roll forming machine?

A metal roof panel roll forming machine is a specialized piece of equipment used in the construction industry to manufacture metal roof panels. Roll forming is a continuous process where a long strip of metal is fed into the machine, and it passes through a series of rolls and forming stations.

The roll forming machine is designed to shape the metal strip into the desired profile of the roof panel. The rolls and forming stations have specific contours and shapes that gradually bend and shape the metal strip. These rolls can be adjusted to create different profiles, such as standing seam, corrugated, or ribbed panels.

The metal strip is typically made of materials like steel, aluminum, or copper, which are durable and weather-resistant. The roll forming machine not only shapes the metal but also cuts it to the required length. It can incorporate various features into the roof panels, such as ribs, flutes, or interlocking mechanisms for easy installation.

Metal roof panel roll forming machines are automated and highly efficient, capable of producing large quantities of roof panels in a short time. They offer precision and consistency in the manufacturing process, resulting in high-quality panels with uniform dimensions.

These panels are widely used in commercial, industrial, and residential construction projects as they provide a durable, lightweight, and attractive roofing solution. Metal roof panels are known for their longevity, resistance to harsh weather conditions, and low maintenance requirements.

What is fence roll forming machine?

A fence roll forming machine is a specialized piece of equipment used to manufacture metal fences through the roll forming process. Roll forming is a continuous bending operation where a long strip of metal is passed through a series of rolls and forming stations to shape it into the desired fence profile.

The fence roll forming machine is designed to create various types of fences, such as chain-link fences, wire mesh fences, and steel picket fences. The machine can handle different types and thicknesses of metal, such as galvanized steel, stainless steel, or aluminum, depending on the desired fence material.

The roll forming machine consists of multiple pairs of rolls and forming stations. Each station performs a specific bending or shaping operation on the metal strip. The rolls gradually shape the metal strip by bending it into the required fence profile, which may include curves, loops, or other intricate patterns.

The machine can also incorporate additional features into the fence, such as notches for wire connections, hooks for interlocking panels, or brackets for gate attachments. Some fence roll forming machines have built-in cutting mechanisms to trim the metal strip to the desired fence length.

Fence roll forming machines are typically automated and can operate at high speeds, enabling efficient production of large quantities of fences. They offer precise and consistent manufacturing, ensuring uniform dimensions and high-quality fence products.

Metal fences manufactured using roll forming machines are widely used in various applications, including residential, commercial, and industrial properties. They provide security, durability, and aesthetic appeal, making them a popular choice for boundary enclosures, privacy barriers, and decorative fencing solutions.

Reviews

There are no reviews yet.