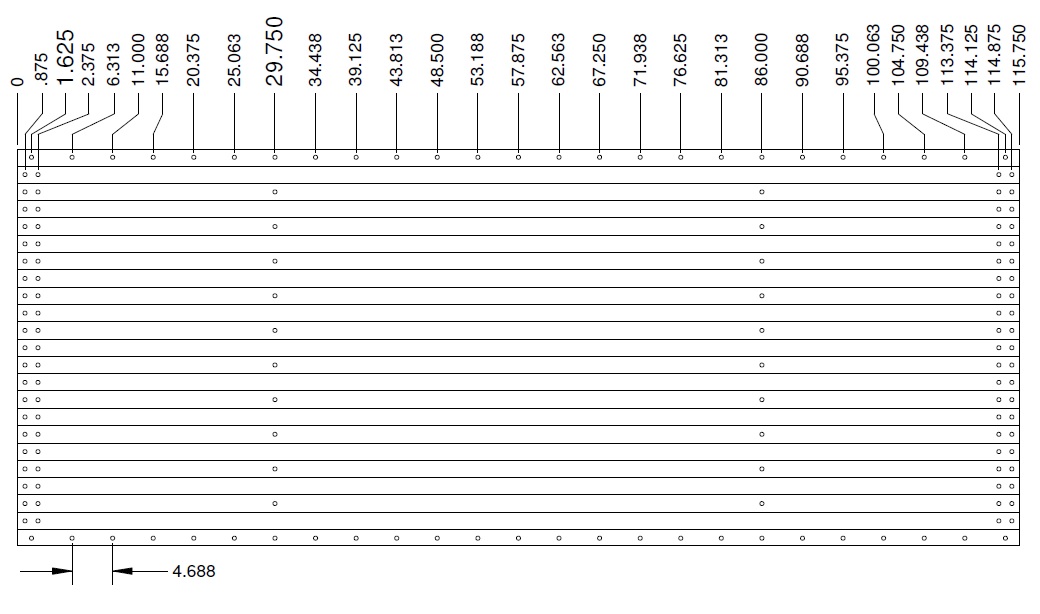

Profile Drawing of Silo corrugated plate roll forming machine factoryplate roll forming machine

Machine list of Silo corrugated plate roll forming machine factory

| Number | Machine list | Number |

| 1 | 5 tons hydraulic de-coiler | 1 set |

| 2 | Feeding &leveling device | 1 set |

| 3 | Hydraulic punching device | 1 set |

| 4 | Main forming machine | 1 set |

| 5 | Hydraulic Cutting device | 1 set |

| 6 | Curving device | 1 set |

| 7 | PLC control system | 1 set |

| 8 | Hydraulic station | 1 set |

| 9 | Gear box drive system | 1 set |

The technique data of Silo corrugated plate roll forming machine factory

- Materials: 1.5-2.0mm galvanized coils

- Forming steps: about 20 stations

- Material of rollers: Gcr15 steel precision-machined, high frequency quenching HRC58-62,

- Material of main shaft : 45# high quality steel (diameter>¢50)

- Cutting: hydraulic cutting; quenching HRC58-62

- Electronic control: PLC control Brand

- Dimension of machine: 11500mmX1350mmX1500mm

- Working speed: about 2-10m/min;

- Drive system: gear box drive

- Main motor power: 22kw

- Curving machine: Curving continuously to make the sheets straight, the min Radius 1.8m, the Radius can be adjustable.

- Cutting: Hydraulic cutting

- Hydraulic station power 22kw

- Voltage: 220V, 60HZ, 3 phases

Working flow of Silo corrugated plate roll forming machine factory

De-coiler—feeding with guide→Straightening device→Punching device→roll forming machine→Curving device→Run out table

Spare parts Pictures for reference

1. 5 tons hydraulic decoiler

- Coil inner Diameter: ¢460-520mm

- Max out diameter of the coil: ¢1500mm

- Max Coil Width: 1250mm

2. Feeding & Leveler device

3. Hydraulic cutting & curving device

4. Control box

what is corrugated roof roll forming machine?

A corrugated roof roll forming machine is a type of industrial equipment used to manufacture corrugated metal roofing sheets. Corrugated metal sheets are widely used in the construction industry for roofing applications due to their durability, strength, and weather resistance.

The roll forming machine is designed to produce continuous lengths of corrugated metal sheets by passing metal coils through a series of rollers. These rollers are specially shaped to gradually shape the metal into the desired corrugated profile. The machine typically consists of a decoiler, which holds the metal coil, followed by a series of rollers, cutting devices, and a final stacker.

The process begins with the decoiler unwinding the metal coil, which is then fed into the roll forming machine. The metal passes through a sequence of rollers, each one bending the metal incrementally to create the corrugated shape. The rollers have strategically placed contours and profiles that gradually shape the metal, forming ridges and valleys to achieve the characteristic corrugated pattern.

Depending on the design and specifications of the machine, various other processes may be incorporated into the production line. These can include embossing patterns onto the metal surface, applying protective coatings or finishes, and cutting the sheets to the desired length. The final product is a continuous length of corrugated metal roofing sheet that can be further cut into individual panels as needed.

Corrugated roof roll forming machines are typically used in large-scale manufacturing facilities and are capable of producing high volumes of roofing sheets efficiently. They provide a cost-effective and automated solution for producing corrugated metal roofing products, contributing to the construction industry’s demand for durable and reliable roofing materials.

how about corrugated roll forming machine price?

The price of a corrugated roll forming machine can vary depending on several factors, including its specifications, features, complexity, and the manufacturer or supplier. Additionally, market conditions and geographic location can also influence the price.

On average, a basic corrugated roll forming machine can range from several thousand dollars to tens of thousands of dollars. However, more advanced and high-capacity machines with additional features and customization options can cost significantly more.

It’s important to note that the price of the machine is just one component of the overall investment. Other factors to consider include shipping or transportation costs, installation expenses, training, maintenance, and potential additional tooling or accessories required.

To get an accurate and up-to-date price for a corrugated roll forming machine, it’s best to contact specific manufacturers, suppliers, or distributors. They can provide you with detailed pricing information based on your specific requirements and provide any additional support or services you may need.

top 5 silo roll forming machine factory

- Sussman Machinery(Wuxi)Co., Ltd. is specialized in manufacturing shape steel cold roll forming machines about 20 years, exporting slitting line and whole group international trade business.

- Bradbury Group: Bradbury Group is a renowned manufacturer of roll forming equipment, including silo roll forming machines. They have a strong presence in the industry and offer a range of solutions for various applications.

- Formtek Group: Formtek Group is a leading global supplier of integrated roll forming systems and related machinery. They have a diverse portfolio of roll forming machines, including those for silo production.

- Yoder Manufacturing: Yoder Manufacturing is a well-established manufacturer of roll forming machinery. They offer a wide range of roll forming equipment, including machines suitable for silo production.

- Samco Machinery: Samco Machinery is known for its innovative roll forming solutions and has a reputation for producing high-quality machinery. They offer customized roll forming machines for various applications, including silo manufacturing.

Reviews

There are no reviews yet.