Станок для формирования рулонных водосточных труб из алюминия PPGI производит полукруглые и прямоугольные водосточные трубы различной длины и размеров, также возможно изготовление труб нестандартной формы в зависимости от требований заказчика. Визуализированный сенсорный дисплей позволяет легко управлять машиной. Введенные параметры могут быть сохранены отдельно для каждого профиля водостока, что позволяет быстро переналаживать станок; управление станком очень простое, для работы с ним требуется всего один человек.

Алюминиевый PPGI водосточный желоб может производить материал толщиной 0,3-0,8 мм, материал PPGI, гальваническую сталь и оцинкованную сталь, также мы можем настроить машину в соответствии с вашим чертежом.

Конструкция машины для формирования рулонных алюминиевых желобов PPGI Rain представляет собой единый блок, что означает, что блок управления и двигатель находятся под рамой машины, когда вы получаете машину, нет необходимости собирать и подключать сложные кабели машины, вам нужно подключить только один главный кабель, после чего машина начинает работать. Это экономит время и место.

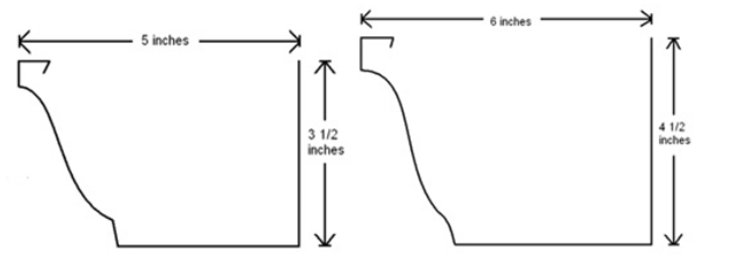

Чертеж профиля

Технологический процесс

Размотка - Подача с направляющей - Формирование валков - Вырубка - Сбор продукции

|

Список машин

|

Пассивный разматыватель 3 тонны | 1 комплект |

| Кормление с гидом | 1 комплект | |

| Основная профилегибочная машина | 1 комплект | |

| Блок управления ПЛК | 1 блок | |

| Гидравлическая станция | 1 блок | |

| Гидравлическая резка | 1 блок | |

| Выходные столы | 2 единицы | |

| Защитная крышка | 1 комплект |

Технические данные

| Предмет номер | Описание |

Предлагаемая спецификация

|

| 1 | Скорость прокатки |

10-15 м/мин (не включая время резки)

|

| 2 | Толщина прокатки | 0,3-0,6 мм |

| 3 | Сырье |

Оцинкованный стальной лист

|

| 6 | Измерение |

Около 7500×1000×1200 (мм)

|

| 7 | Масса | Около 6 тонн |

| 8 | Роликовые станции |

Около 16 станций

|

| 9 | Материал ролика |

Сталь кузнечная 451ТП5Т, покрытая хромом

|

| 10 | Диаметр вала |

Φ70мм, материал кованая сталь 45#

|

| 11 | Передача инфекции |

По цепочке 1 дюйм

|

| 12 | Материал цепи |

Сталь кованая 451ТП5Т с частотной закалкой, 12А

|

| 14 | Материал резки |

Cr12Mov с закалкой HRC58-62°

|

| 15 | Толерантность | 6 м ± 1,5 мм |

| 16 | Рамка | Сталь типа Н |

Подробности каждой композиции

1. Пассивный разматыватель 3T

- Внутренний диаметр катушки: ¢460мм~520мм

- Максимальный диаметр катушки: ¢800 мм

- Расширение: с 4 ладонями, с тормозом

- Максимальная ширина катушки: 500 мм

2. Резка

(1) Резка после формовки: Отрежьте лист после формовки до необходимой длины.

(2) Движение резки: Основной станок автоматически останавливается, и происходит резка. После резки основной станок автоматически включается.

(3) Материал лезвия: CR12Mov с термообработкой

(4) Измерение длины: автоматическое измерение длины

(5) Допустимое отклонение длины: 10 м ± 2 мм.

3. Выносные столы

- Длина: 2 метра

- Количество: 2 шт.

4. Блок управления

(1) Источник питания: 380 В, 50 Гц, 3 фазы (настраивается по запросу)

(2) Автоматическое измерение длины и количества;

(3) Длина и количество контролируются ПЛК

(4) Неточность длины можно легко исправить.

(6) Панель управления: кнопочный переключатель и сенсорный экран

(7) Единица длины: миллиметр (включается на панели управления)

что такое машина для формирования рулонов водосточных труб?

Рулонный станок предназначен для изготовления водосточных труб определенного профиля и размеров. Как правило, она состоит из ряда роликов, направляющих и режущих инструментов, которые формируют непрерывный металлический рулон в желаемую форму водостока. Машина управляется компьютером и может быть настроена на производство водосточных труб различных размеров, материалов (например, алюминия или стали) и профилей (например, К-образных или полукруглых).

Процесс начинается с подачи плоского металлического рулона в машину. Рулон проходит через ряд роликов, которые постепенно изгибают и придают металлу форму профиля желоба. По мере придания желобу нужной формы можно использовать дополнительные ролики или прессовые инструменты для создания таких элементов, как фланцы или монтажные кронштейны. Наконец, желоб обрезается до нужной длины и выбрасывается из машины.

Станки для формирования рулонных водостоков обладают рядом преимуществ по сравнению с традиционными методами производства водостоков. Они обеспечивают эффективное крупносерийное производство с неизменным качеством и точностью. Машины могут обслуживаться относительно неквалифицированным персоналом, что снижает трудозатраты и повышает производительность. Кроме того, они позволяют быстро менять профили и размеры желобов, что делает их универсальными для различных требований заказчика.

5 лучших машин для формирования рулона водосточного желоба в Китае

- Sussman Machinery(Wuxi)Co., Ltd. (Уси, Цзянсу)

- Tianjin Haixing Imp & Exp Co., Ltd. (Тяньцзинь)

- Компания Cangzhou Forward Roll Forming Machinery Manufacturing Co. (Канчжоу, Хэбэй)

- Liming Stamping Forming Machine Co., Ltd. (Ботоу, Хэбэй)

- Компания Jiangsu Huazhong Roll-Forming Machine Co. (Уси, Цзянсу)

что такое машина для холодной прокатки водосточных труб?

Станок холодной вальцовки водостоков - это особый тип вальцовочного оборудования, используемого для производства водосточных труб. Она предназначена для формирования водосточных труб из рулонов различных металлов, например, алюминия или стали, методом холодной прокатки.

Как правило, станок состоит из ряда роликов, направляющих и режущих инструментов, которые придают металлическому рулону желаемый профиль желоба. Металлический рулон подается в машину и, проходя через ролики, постепенно изгибается и принимает форму желоба. Дополнительные ролики и прессующие инструменты могут использоваться для создания специфических элементов и деталей, таких как фланцы, отверстия для водосточных труб или монтажные кронштейны.

Одной из основных характеристик машины для холодной прокатки водостоков является использование процесса холодной прокатки. В отличие от горячей прокатки, при которой металл нагревается, холодная прокатка осуществляется при комнатной температуре, что позволяет использовать ее для таких материалов, как алюминий и сталь. Этот процесс обеспечивает такие преимущества, как точность формы, стабильное качество и повышенная скорость производства.

Станки для холодной прокатки желобов могут быть настроены на производство желобов различных размеров, профилей (например, К-образных или полукруглых) и толщины. Часто они оснащаются системами компьютерного управления для точного контроля и автоматизации, что обеспечивает эффективность и точность производства.

Эти машины играют важнейшую роль в производстве водосточных систем, обеспечивая массовое производство высококачественных водосточных желобов с неизменными размерами и профилями.

Топ-5 способов, которыми машина для формирования желоба может помочь вашему дому или бизнесу

Отзывы

Отзывов пока нет.