the necessary of Maintenance and upkeep the siding roll forming machine

-

Máquina formadora de rollos de dos pisos

Máquina formadora de rollos de dos pisos -

Máquina formadora de rollos de canal de sombrero de copa de listón de techo Omega

Máquina formadora de rollos de canal de sombrero de copa de listón de techo Omega -

Máquina perfiladora de láminas corrugadas PPGI de alta velocidad

Máquina perfiladora de láminas corrugadas PPGI de alta velocidad -

máquina formadora de rollos de viga superior cruzada para casa contenedor de 3 mm de espesor

máquina formadora de rollos de viga superior cruzada para casa contenedor de 3 mm de espesor -

Máquina perfiladora de tapas de cumbrera de techo Aluzinc PPGI

Máquina perfiladora de tapas de cumbrera de techo Aluzinc PPGI -

Máquina perfiladora de paneles de pared de techo para decoración

Máquina perfiladora de paneles de pared de techo para decoración

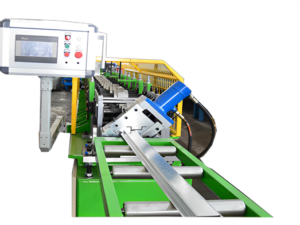

Perfiladoras de revestimientos are specialized equipment used in the construction industry to fabricate metal or other materials into continuous lengths of siding for building exteriors. These machines can produce siding in a wide range of colors, patterns, and profiles, and they are essential for meeting the unique design and functionality requirements of various construction projects.

Proper maintenance and upkeep of siding roll forming machines are necessary for their longevity and to ensure that they continue to produce high-quality, consistent products. Routine maintenance of the machine can help prevent breakdowns, reduce the risk of accidents, and increase the efficiency of the production process.

Neglecting maintenance can lead to a wide range of problems, including reduced accuracy and consistency of the produced siding, higher maintenance costs, and decreased production efficiency. Additionally, without proper upkeep, the machine’s components may wear out more quickly, leading to more frequent replacements and downtime.

Therefore, regular maintenance and upkeep of a siding roll forming machine are essential for the long-term success of the construction project, as well as the profitability and sustainability of the business that operates the machine.

The Safety precautions of Maintenance and upkeep the siding roll forming machine

Ensuring safety is a critical aspect of maintaining and cleaning a siding roll forming machine. Here are some common safety measures and procedures that should be followed:

Turn off the machine: Before performing any maintenance or cleaning, make sure the machine is turned off and unplugged from the power source.

Lockout the power supply: Use a lockout/tagout system to prevent anyone from accidentally turning on the machine while you are working on it.

Wear Equipos de protección individual (EPI): Wear appropriate PPE, including gloves, safety glasses, and hearing protection, to protect yourself from sharp edges, hot surfaces, and noise.

Clean the workspace: Remove any debris, tools, and other materials from the workspace to prevent slips, trips, and falls.

Follow the manufacturer’s instructions: Follow the manufacturer’s instructions and warnings when performing maintenance or cleaning.

Be aware of moving parts: Be mindful of the moving parts of the machine, especially the rollers and blades, and keep your fingers and clothing away from them.

Do not override safety features: Do not attempt to bypass any safety features or guards on the machine.

Do not operate the machine with damaged parts: Do not operate the machine if any parts are damaged or malfunctioning.

By following these safety measures and procedures, you can reduce the risk of accidents and injuries when performing maintenance and cleaning tasks on your siding roll forming machine.

The Troubleshooting of Maintenance and upkeep the siding roll forming machine

Here are some common problems that can occur with a siding roll forming machine, along with some basic maintenance procedures that can prevent these problems from occurring in the first place and how to troubleshoot them:

Uneven or inconsistent material thickness: If the machine produces inconsistent material thickness, it can lead to problems with the quality and appearance of the produced siding. To prevent this problem, clean the rollers and blades regularly and ensure they are properly lubricated. Check the machine’s alignment and adjust it as needed. If you notice this problem while operating the machine, stop production, and check the material thickness gauge, rollers, and blades.

Machine vibration or noise: Excessive vibration or noise can indicate worn or damaged components such as the bearings, gears, or shafts. To prevent this problem, regularly lubricate the machine’s moving parts, and inspect for any worn or damaged components. If you notice this problem, stop the machine and inspect it for any damage or worn components.

Jamming or clogging: The accumulation of debris or a buildup of material can cause the machine to jam or clog, leading to production downtime. To prevent this problem, clean the machine regularly and remove any debris or buildup of material. If you notice this problem, stop the machine and remove the blockage.

Electrical problems: Electrical problems can occur due to various reasons, such as loose connections, faulty wiring, or tripped circuit breakers. To prevent this problem, inspect the electrical connections and components regularly and tighten any loose connections. If you notice an electrical problem, turn off the machine and check the wiring and circuit breakers.

Wear and tear of components: Wear and tear of components such as rollers, blades, or bearings can cause the machine to produce low-quality siding or malfunction. To prevent this problem, regularly lubricate the machine’s moving parts, inspect for any worn or damaged components, and replace them as needed. If you notice this problem, inspect the machine for any worn or damaged components and replace them as needed.

By following these basic maintenance procedures, you can prevent many common problems from occurring with your siding roll forming machine.

The Maintenance And Upkeep of siding roll forming machine

Here are some steps to maintain and upkeep your siding roll forming machine:

Clean the machine regularly: Dirt, debris, and metal shavings can accumulate on the machine, causing wear and tear of its components. Therefore, it’s essential to clean the machine regularly using a cloth, air compressor, or vacuum.

Lubricate the moving parts: The machine’s moving parts such as rollers, blades, and bearings require regular lubrication to prevent friction and wear. Consult the machine’s manual for the recommended lubrication schedule and use the appropriate type of lubricant.

Inspect the machine’s components: Regular inspection of the machine’s components is critical to identify any worn or damaged parts that can affect the machine’s performance. Inspect the rollers, blades, bearings, and electrical components, and replace any damaged or worn parts as needed.

Check the alignment of the machine: The machine’s alignment can affect the quality and consistency of the produced siding. Check the machine’s alignment regularly and adjust it as needed.

Verify the electrical connections: Electrical problems can cause the machine to malfunction or stop working. Therefore, verify the electrical connections regularly and ensure they are tight and secure.

Replace worn or damaged components: Worn or damaged components can cause the machine to produce low-quality siding or stop working. Therefore, replace any worn or damaged components, such as rollers, blades, or bearings, as soon as possible.

Train your employees: Train your employees on the proper use and maintenance of the machine to prevent accidents, improve efficiency, and reduce downtime.

By following these maintenance and upkeep steps, you can prolong the life of your siding roll forming machine, ensure optimal performance, and prevent unnecessary downtime. Regular maintenance and inspection are essential to prevent problems and reduce maintenance costs in the long run.

In summary, to ensure the longevity and efficient operation of the machine, regular maintenance and upkeep are essential. This includes cleaning the machine, lubricating the moving parts, inspecting the components, verifying the electrical connections, checking the machine’s alignment, replacing any worn or damaged parts, and training employees on proper use and maintenance. By following these maintenance and upkeep steps, you can prolong the life of your siding roll forming machine, ensure optimal performance, and prevent unnecessary downtime. If you are in the market for a siding roll forming machine, be sure to choose a reputable supplier like Suhang Machinery to ensure high-quality, reliable equipment.