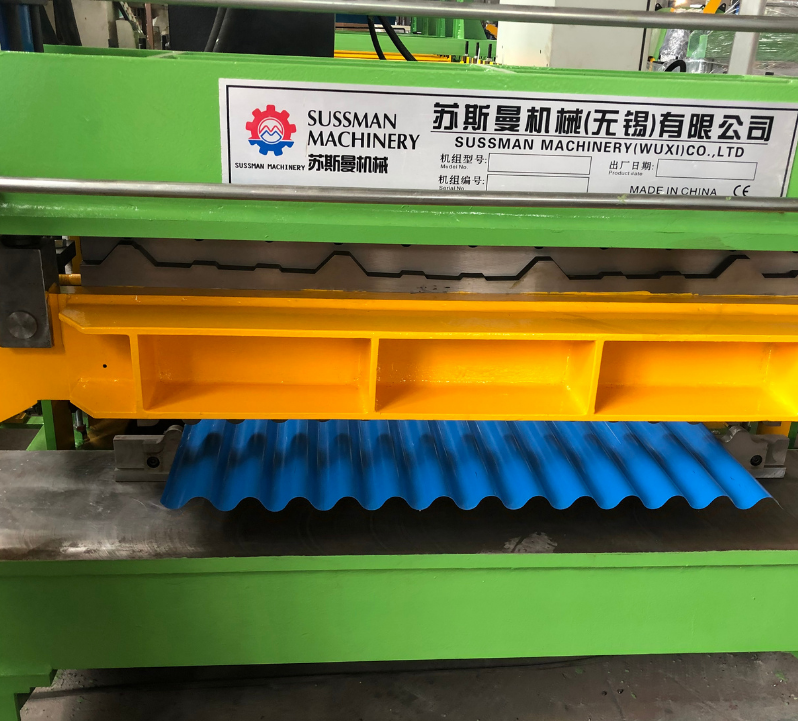

Dek ganda pembentukan gulungan mesin dapat menghasilkan dua gambar profil yang berbeda, yang dapat menghemat lebih banyak ruang dan uang dibandingkan dengan dua mesin yang berbeda, kisaran ketebalan material 0,3-0,8mm atau 0,12-0,4mm, bahan PPGI, baja tahan karat dan baja galvanis

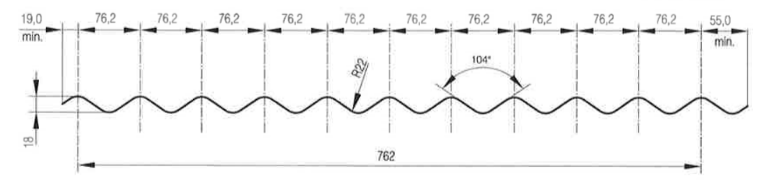

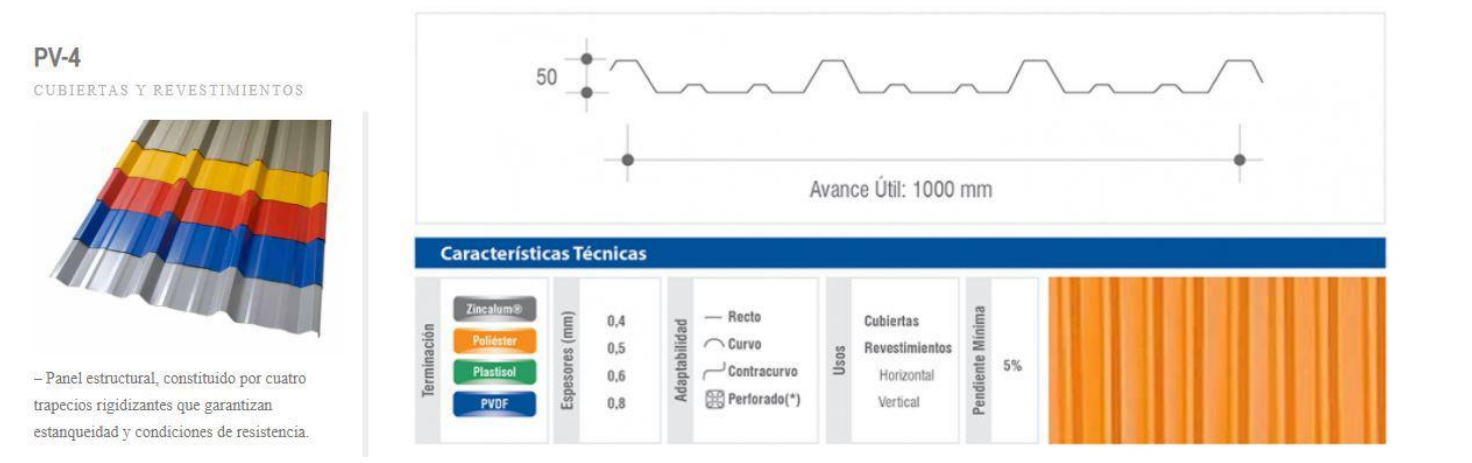

Anda dapat memilih dua gambar profil yang berbeda, misalnya:

- Lembaran atap dan lembaran bergelombang

- Lembaran dinding dan lembaran bergelombang

- Lembaran atap dan lembaran dinding

- Genteng kaca dan lembaran atap

- Ubin kaca dan lembaran bergelombang

Mesin pembuat gulungan lapisan ganda tidak dapat bekerja pada saat yang sama, satu kali hanya menghasilkan satu profil lapisan. Ada satu kopling sebagai satu sisi mesin, dan Anda cukup menggerakkan satu roda pegangan untuk membuat profil lapisan lainnya, dibutuhkan beberapa detik, dan seluruh lini hanya membutuhkan satu orang untuk mengoperasikannya, sangat mudah

Gambar Profil

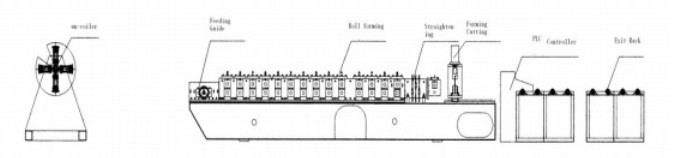

Proses teknologi

Membuka gulungan - Pembentukan gulungan - Pemotongan hidrolik - Pengumpulan produk

|

Daftar Mesin

|

Decoiler manual 5 ton | 1 set |

| Memberi makan dengan pemandu | 1 set | |

| Mesin pembentuk gulungan utama | 1 set | |

| Kotak Kontrol PLC | 1 unit | |

| Alat pemotong hidrolik | 1 unit | |

| Meja pasif 2m | 2 unit | |

| Suku cadang | 1 paket | |

| Penutup pengaman | 1 set |

Data teknis

| Nomor | Item | Jenis unit | RF-DL |

| 1 | Ketebalan Baja | mm |

0,11-0,3mm untuk bergelombang, 0,3-0,8mm untuk lembaran trapesium, Baja Berwarna / Kumparan Baja Galvanis

|

| 2 | Kecepatan Pembentukan | m/mnt | 8-15 |

| 3 | Dudukan rol | berdiri |

Lapisan atas adalah sekitar 22 stasiun

Lapisan bawah sekitar 20 stasiun |

| 4 | Bahan Rol | mm |

Baja 45#, dilapisi dengan krom

|

| 5 | Bahan dan diameter poros | mm |

Baja Ф75 45#, dilapisi dengan krom

|

| 6 | Tenaga Motor Utama | Kw | 7.5 |

| 7 | Daya potong hidrolik | Kw | 4 |

| 8 | Tekanan hidrolik | Mpa | 12 |

| 9 | Sumber Daya listrik |

380V, 50HZ, 3 fase

|

|

| 10 | Toleransi | mm | ±1.5 |

| 11 |

Bahan pemotongan

|

Cr12Mov HRC58-62

|

|

| 12 | Sistem pengaturan |

PLC dengan layar sentuh

|

|

| 13 | Berat mesin utama | T | 10T |

| Catatan: motor utama, stasiun hidrolik, dan kotak kontrol berada di bawah rangka mesin untuk menghemat tempat, layar sentuh menggantung | |||

Detail dari setiap komposisi

1. Uncoiler: 5 ton de-coiler manual

- Diameter bagian dalam koil: ¢460-520mm

- Max out diameter koil: ¢1250mm

- Lebar Kumparan Maks: 1250mm

2. Pemotongan Hidraulik

- Gerakan pemotongan: Mesin utama berhenti dan kemudian memotong secara otomatis. Setelah pemotongan, mesin utama akan hidup kembali secara otomatis.

- Bahan pisau: CR12Mov dengan perlakuan panas

- Pengukuran panjang: Secara otomatis

- Ketebalan pemotongan: 0.5-1.0mm

- Daya Stasiun Hidraulik: 4kw

3. Meja pasif 2 meter

- Ini mengadopsi baja yang dilas dan roller yang didukung untuk mengirimkan produk.

- Ukuran: 2000 * 1300 * 800mm

4. Kotak Kontrol

- Pemasok daya: 380V, 50 Hz, 3Phase

- Pengukuran panjang & kuantitas secara otomatis;

- Panjang & kuantitas dikendalikan oleh PLC

- Ketidaktepatan panjang dapat diubah dengan mudah.

- Panel kontrol: Sakelar tipe tombol dan layar sentuh

- Satuan panjang: milimeter (diaktifkan pada panel kontrol)

Apa itu mesin pembuat gulungan dek?

Mesin pembuat gulungan dek, juga dikenal sebagai mesin pembuat gulungan dek logam atau mesin pembuat gulungan dek baja, adalah peralatan industri khusus yang digunakan dalam industri konstruksi untuk membuat panel atau lembaran dek logam. Panel decking logam biasanya digunakan sebagai komponen struktural pada bangunan, terutama untuk membangun lantai, atap, dan mezanin.

Mesin pembuat gulungan dek mengambil gulungan logam, biasanya baja, dan memprosesnya melalui serangkaian rol dan cetakan. Rol dan cetakan ini secara bertahap membentuk logam menjadi profil tertentu, yang merupakan bentuk dan desain yang diinginkan dari panel penghiasan logam. Proses melewatkan logam melalui rol dan cetakan dikenal sebagai roll forming.

Mesin ini dilengkapi dengan berbagai stasiun, seperti stasiun decoiling, leveling, punching, roll forming, cutting, dan stacking. Setiap stasiun menjalankan fungsi tertentu dalam keseluruhan proses manufaktur. Kumparan logam dimasukkan ke dalam mesin, dan melewati stasiun-stasiun ini untuk menjalani operasi yang diperlukan untuk menghasilkan panel penghiasan logam akhir.

Mesin pembuat gulungan dek mampu menghasilkan panel dek logam dengan bentuk, ukuran, dan profil yang konsisten. Mesin ini menawarkan keunggulan seperti efisiensi produksi yang tinggi, presisi, dan opsi penyesuaian. Panel decking logam yang dihasilkan tahan lama, ringan, dan memiliki kemampuan menahan beban yang sangat baik, sehingga cocok untuk berbagai aplikasi konstruksi.

Secara keseluruhan, mesin pembuat gulungan dek memainkan peran penting dalam pembuatan panel dek logam, memberikan solusi yang efisien dan otomatis untuk memproduksi komponen penting yang digunakan dalam industri konstruksi.

keuntungan dari mesin pembuat gulungan dek ganda

Mesin roll forming dek ganda menawarkan beberapa keunggulan dibandingkan mesin dek tunggal. Berikut adalah beberapa keuntungan utama:

- Meningkatkan efisiensi produksi: Mesin roll forming dek ganda memiliki dua set stasiun roll forming, yang memungkinkan pembentukan dua profil yang berbeda atau dua lapisan dari profil yang sama secara bersamaan. Hal ini menghasilkan efisiensi produksi yang lebih tinggi dibandingkan dengan mesin dek tunggal, karena mengurangi waktu yang diperlukan untuk membentuk beberapa profil.

- Desain hemat ruang: Dengan memanfaatkan dua tingkat stasiun roll forming dalam mesin yang sama, mesin roll forming dek ganda membutuhkan lebih sedikit ruang lantai dibandingkan dengan memiliki dua mesin dek tunggal yang terpisah. Hal ini sangat bermanfaat di pabrik atau bengkel dengan ruang terbatas.

- Keserbagunaan: Mesin roll forming dek ganda menawarkan keserbagunaan yang lebih besar dalam memproduksi berbagai macam profil. Mesin ini dapat menangani berbagai bentuk, ukuran, dan bahan profil di setiap dek, sehingga memungkinkan peningkatan fleksibilitas dalam pembuatan berbagai produk. Keserbagunaan ini membuat mesin ini cocok untuk beragam industri dan aplikasi.

- Penghematan biaya: Meskipun investasi awal pada mesin roll forming dek ganda mungkin lebih tinggi daripada mesin dek tunggal, penghematan biaya secara keseluruhan dapat menjadi signifikan. Dengan peningkatan efisiensi produksi dan kemampuan untuk memproduksi beberapa profil secara bersamaan, mesin ini membantu mengurangi biaya tenaga kerja, konsumsi energi, dan biaya perawatan, yang mengarah pada penghematan jangka panjang.

- Kapasitas produksi yang ditingkatkan: Dengan dua tingkat stasiun roll forming, mesin dek ganda dapat mengakomodasi volume produksi yang lebih tinggi dibandingkan dengan mesin dek tunggal. Hal ini sangat bermanfaat bagi industri dengan persyaratan produksi skala besar atau tenggat waktu produksi yang ketat.

- Kontrol kualitas yang lebih baik: Mesin roll forming dek ganda menawarkan kontrol kualitas yang lebih baik karena memungkinkan pembentukan profil yang tepat dan konsisten. Setiap dek dapat disesuaikan secara independen untuk memastikan dimensi yang akurat, toleransi yang ketat, dan produk akhir berkualitas tinggi.

Penting untuk dicatat bahwa keuntungan yang tercantum di atas adalah keuntungan umum yang terkait dengan mesin roll forming dek ganda. Keuntungan spesifik dapat bervariasi tergantung pada desain, fitur, dan persyaratan proses produksi mesin.

Apa area aplikasi utama dari mesin pembuat gulungan dek logam?

Mesin roll forming dek logam terutama digunakan dalam industri konstruksi untuk produksi dek logam atau sistem penghiasan lantai. Dek logam ini biasanya digunakan sebagai komponen struktural dalam berbagai aplikasi. Berikut adalah area aplikasi utama mesin pembuat gulungan dek logam:

- Bangunan Komersial dan Industri: Dek logam yang diproduksi oleh mesin roll forming banyak digunakan pada bangunan komersial dan industri untuk membangun lantai, atap, dan tingkat mezanin. Dek logam memberikan dukungan struktural, stabilitas, dan platform untuk pemasangan material lantai.

- Bangunan Bertingkat dan Struktur Bertingkat Tinggi: Dek logam memainkan peran penting dalam konstruksi bangunan bertingkat dan struktur bertingkat. Mereka menyediakan platform yang kuat, ringan, dan tahan lama untuk menopang pelat beton, memperkuatnya, dan mendistribusikan beban ke seluruh struktur. Dek logam meningkatkan integritas struktural keseluruhan dan kapasitas penahan beban bangunan.

- Sistem Lantai Komposit: Dek logam sering digunakan sebagai bagian dari sistem lantai komposit, di mana mereka bekerja bersama dengan beton. Dek logam berfungsi sebagai bekisting selama proses penuangan beton dan kemudian berfungsi sebagai komponen struktural permanen. Kombinasi dek logam dan beton ini menciptakan lantai komposit yang efisien dan kuat.

- Sistem Atap: Dek logam yang diproduksi oleh mesin roll forming digunakan sebagai dasar untuk sistem atap. Mereka menyediakan fondasi yang stabil dan aman untuk berbagai bahan atap, seperti insulasi, membran, dan lapisan kedap air. Metal deck juga berkontribusi terhadap ketahanan api dan efisiensi energi sistem atap secara keseluruhan.

- Konstruksi Jembatan: Dek logam digunakan dalam konstruksi jembatan untuk membentuk dek jembatan. Mereka menawarkan solusi yang ringan dan ekonomis yang membantu mengurangi berat keseluruhan struktur jembatan. Dek logam memberikan kekuatan, daya tahan, dan ketahanan terhadap korosi, sehingga cocok untuk jembatan pejalan kaki dan kendaraan.

- Proyek Infrastruktur dan Industri: Dek logam dapat digunakan di berbagai proyek infrastruktur dan industri, termasuk gudang, pabrik, pusat distribusi, dan fasilitas penyimpanan. Mereka menyediakan sistem lantai yang kuat dan andal yang dapat menahan beban berat, lalu lintas pejalan kaki, dan pengoperasian peralatan.

- Perkuatan dan Renovasi: Dek logam juga digunakan dalam proyek perkuatan dan renovasi untuk memperkuat struktur yang sudah ada atau mengubahnya menjadi bangunan bertingkat. Dek logam dapat dipasang di atas struktur yang sudah ada, memberikan lantai tambahan dan meningkatkan stabilitas keseluruhan dan kapasitas penahan beban.

Ini adalah area aplikasi utama dari mesin pembuat gulungan dek logam. Namun, perlu dicatat bahwa aplikasi spesifik dapat bervariasi tergantung pada praktik konstruksi regional dan kode bangunan.

Ulasan

Belum ada ulasan.